Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Latin American applied research

versão impressa ISSN 0327-0793

Lat. Am. appl. res. v.38 n.3 Bahía Blanca jul. 2008

Effect of the sterilization process on physical and mechanical properties of the Bonacryl bone cement

L. Morejón1, J. A. Delgado1, L. Agüero1, M. Rapado2, M. P. Ginebra3, F. J. Gil3 and E. Mendizábal4

1Centro de Biomateriales, Universidad de La Habana. C. Habana, CP 10400, Cuba. lizette@biomat.uh.cu

2 Centro de Aplicaciones Tecnológicas y Desarrollo Nuclear, CP 10600, Cuba

3 Universidad Politécnica de Cataluña, Barcelona, CP 08028. España

4 Universidad de Guadalajara, Jalisco. CP 44430. México

Abstract — The use of bone cements of poly(methyl methacrylate) (PMMA) to fix artificial prosthesis to the human body is a habitual method in orthopedic surgery. The hip and the knee joints have a very complex biomechanics and support high loads, for these reasons, acrylic bone cements have to comply with international standards in order to secure the biofuncionality and durability of the implant.

In this work we report the effect of sterilization by ethylene oxide or gamma radiation on the BONACRYL Cuban cement. We determined how sterilization methods affect the molecular weight of the polymer as well as its quasi-static mechanical properties. The results demonstrated that the gamma radiation modifies the molecular weight of the PMMA although the compression and bending strength were not affected by the sterilization process applied.

Keywords — Bone Cements. Poly(methylmetha-crylate). Sterilization. Mechanical Properties.

I. INTRODUCTION

Acrylic bone cements are widely used in orthopedic surgery to fix artificial prostheses in the body osseous structure (Charnley, 1970). The success of a hip arthroplasty depends on a great number of factors. Statistical data show that the cemented prostheses fail due to septic processes, the mechanical breakage of the acrylic cement or prostheses, or the loosening of bone/cement and cement/prostheses interfaces (Horowitz et al., 1993). Bone cement failure through crack initiation, propagation and fracture may be a critical factor in the process of failure of the implant. Since in most of the cases the cement contributes to the failure of the implant, it is necessary for the cement to have the adequate properties to guarantee implants durability (Horowitz et al., 1993; Willert et al., 1990).

The acrylic bone cement is composed of a solid and a liquid part. The solid part consists of PMMA beads, barium sulfate as a radiopaque material, and benzoyl peroxide as the initiator. The liquid part is usually formulated by using methyl methacrylate as the monomer, hydroquinone, which prevents earlier polymerization and N,N-dimethyl-p-toluidine, which accelerates initiator decomposition. Cement setting takes from 5 to 15 minutes which permits a firm and immediate anchorage of the implant to the body structure. Cement setting takes place as a result of radical polymerization. Because of the complexity of the biomechanics of the hip joint and the high loads that they have to support some static mechanical properties have to comply with international standards in order to secure the biofuncionality and durability of the implant (ISO 5833, 2002).

In this work we report the effect of the sterilization by ethylene oxide and gamma radiation on the Bonacryl Cuban cement on molecular weight of the polymer beads and in some quasi-static mechanical properties of the bone cement.

II. METHODS

A. Bone Cement

The liquid part of the Bonacryl bone cement is composed by 97.3% vol. methyl methacrylate, 2.7% vol. N,N-dimethyl-p-toluidine and 80 ppm of hydroquinone. The solid part of the Bonacryl cement consists on 90% wt. of a mixture of two types of PMMA beads (A and B) and 10% wt. of barium sulfate from Fluka. The bead mixture was prepared by mixing A and B beads (Table 1) in a ball mill in a proportion of 80/20 wt.By means of Iodinemetry it was found that the PMMA beads had a 2.63 ± 0.02% of residual peroxide, which is in the range of the amount required for the polymerization of the Bonacryl, so more peroxide was not added to the solid formulation. A 2/1 solid/liquid ratio was used for all formulations

To determine the effect of sterilization, 25 samples consisting each one in 1.0 g of the solid part were sterilized with ethylene oxide using a ED-100 Sakura equipment. Samples were wrapped with paper and introduced into the sterilization camera containing 20% ethylene oxide and 80% carbon dioxide, where they were maintained at 60 °C for 6 hours. Then the samples were desgasificated for 8 hours. Also, other 25 samples consisting each one in 1.0 g of the solid part were sterilized by gamma radiation using an laboratory blinded irradiator (PXM-Gamma 30, Russian made) using a Co60 source at a dose of 25 kGy.

B. Beads characterization

The molecular weight of polymeric beads, before and after sterilization, were determined by viscosimetry at 23.0± 0.1°C using an Oswald viscosimeter. The beads were dissolved in chloroform to obtain solutions containing 1.0% wt of PMMA and the flow time of the solution was used to obtain the reduced viscosity using the following equation:

Reduced viscosity (η) = (t1/t0 - 1)*100/c (1)

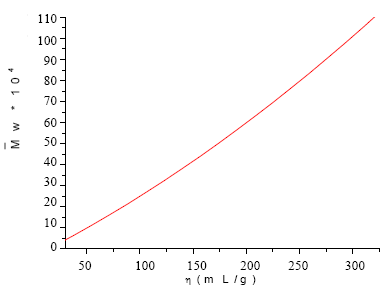

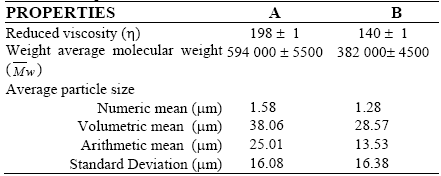

where t0 is the chloroform flow time, t1 is the PMMA solution flow time and c is the concentration (in percent) of PMMA in the solution. The weight average molecular weight ( ) of the PMMA beads was obtained by using the reduced viscosity and the Röhm calibration curve to determine the molecular weight of PMMA cements (Kühn, 2000) (Fig. 1). Beads particle size distribution was determined in a Sedigraph 5100, by measuring the dispersion of 1.0 g of the PMMA beads in water (Fig. 2).

) of the PMMA beads was obtained by using the reduced viscosity and the Röhm calibration curve to determine the molecular weight of PMMA cements (Kühn, 2000) (Fig. 1). Beads particle size distribution was determined in a Sedigraph 5100, by measuring the dispersion of 1.0 g of the PMMA beads in water (Fig. 2).

Fig. 1. Röhm calibration curve: Reduced Viscosity (η) vs. Weight average molecular weight ( ).

).

Glass transition temperature of the beads, before and after sterilization were determined in a Perkin Elmer DSC7 calorimeter at a heating rate of 10 ºC/min.

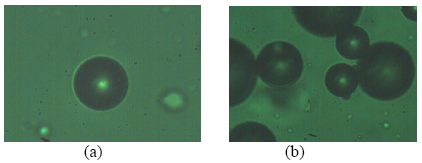

Microphotographies were taken at an amplification of 50X in an Olympus optical microscope.

Maximum temperature and setting time was determined by using 1.0 g of the mixture of the solid and the liquid part. The mixture was introduced in an ultrahigh molecular weight polyethylene mold thermally isolated and the temperature was followed with a HANNA thermometer using a HI9053 thermocouple. Setting time (ts) was the time when reaction temperature is one half of the sum of room and maximum temperatures.

C. Mechanical tests

To determine the effect of the sterilization procedure on compression and bending properties, three types of cement samples were prepared: in the first type of sample of solid part were not sterilized; in the second type the solid part were sterilized by ethylene oxide and in the third one the solid part were sterilized with gamma irradiation.

Compression and bending test specimens were made following ISO 5833 specifications. The compression specimens were cylinders having a 6 mm in diameter and 12 mm in height. Prior the tests, the samples were conditioned at 23±2 °C for 24±2 hours. The compression tests were carried out in a Universal Testing Machine MTS BIONIX 858. The cross-head speed employed was 20 mm/min. At least five specimens were tested, and the mean and standard deviation is reported for each sample. Flexure tests were done on an Instron Universal Testing Machine in three points bending using a cross-head speed of 1.0 mm/min. The flexure specimens were flat rectangular bars with the following dimensions: 60x8.5x3mm. Prior to the tests the samples were conditionated at 37 ± 0.1°C in water for 50 hours.

Fig. 2. Particle size distribution of the PMMA beads a) A b) B

III. RESULTS AND DISCUSSION

Table 1 shows the reduced viscosity, the weight average molecular weight ( ), and the average particle size of the beads before sterilization treatment. The particle size distribution was unimodal in both cases and the average particle size was in the range of particle size of commercial materials. Optical microscopy was used to observe that the beads were spherical. A mixture of PMMA beads of A/B (80/20 wt) was used to obtain a rapid integration of the liquid part with the solid part. B beads had smaller particle size and lower molecular weight, fact that facilitates their dissolution by the MMA monomer before the setting occurs.

), and the average particle size of the beads before sterilization treatment. The particle size distribution was unimodal in both cases and the average particle size was in the range of particle size of commercial materials. Optical microscopy was used to observe that the beads were spherical. A mixture of PMMA beads of A/B (80/20 wt) was used to obtain a rapid integration of the liquid part with the solid part. B beads had smaller particle size and lower molecular weight, fact that facilitates their dissolution by the MMA monomer before the setting occurs.

The cement was prepared and its setting properties were determined under standard conditions. After mixing the solid and the liquid part it was observed that the mixture had adequate manipulation properties and its setting time (5.61±0.02min) and maximum tempe-rature (46.9±0.4 °C) were in accordance with the ISO 5833 standard.

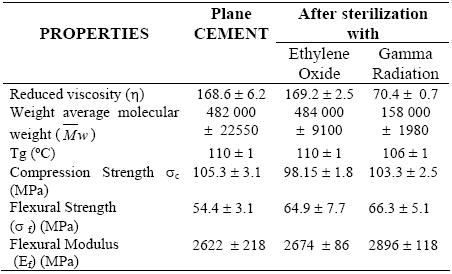

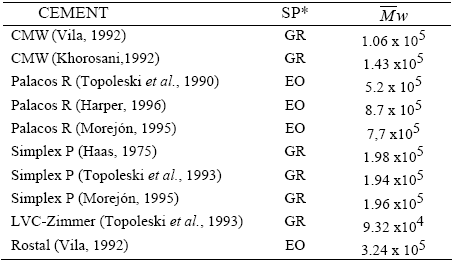

Table 2 shows that  decreased with the gamma radiation but it didn't with the ethylene oxide treatment. However the

decreased with the gamma radiation but it didn't with the ethylene oxide treatment. However the  of the beads is within the

of the beads is within the  reported for the commercial beads used in acrylic bone cements (Table 3). Table 2 shows that the Tg was modified only when the sterilization was done with gamma radiation, and it can be explained by the decrease in molecular weight. It was reported a decrease in Tg of 12 ºC when PMMA was gamma irradiated with 23.5 kGy (O´Rourke Muisener et al., 2002).

reported for the commercial beads used in acrylic bone cements (Table 3). Table 2 shows that the Tg was modified only when the sterilization was done with gamma radiation, and it can be explained by the decrease in molecular weight. It was reported a decrease in Tg of 12 ºC when PMMA was gamma irradiated with 23.5 kGy (O´Rourke Muisener et al., 2002).

Microphotographies of beads before and after gamma radiation show that there are not noticeable changes in surface or colour after the sterilization procedure

Table 1. Properties of PMMA beads

Table 2. Properties of bone cement non sterilized and sterilized

Fig. 3. Microphotographies of beads before (a) and after (b) gamma irradiation.

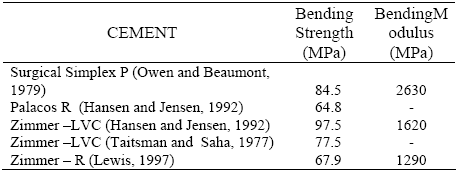

Table 2 also shows that bending strength and bending are practically unmodified by the sterilization procedure, even in the case of gamma irradiation where the beads had a lower  . Graham et al. (2000), reported that when a Palacos bone cement was gamma irradiated with a dose of 100 kGy, which is larger than that used in this work, there was a decrease in fracture resistance when compared with ethylene oxide sterilization method. The advantage of gamma irradiation is that it has a high penetration capacity which allows the direct sterilization of the sample when it is packed. However, gamma irradiation affects

. Graham et al. (2000), reported that when a Palacos bone cement was gamma irradiated with a dose of 100 kGy, which is larger than that used in this work, there was a decrease in fracture resistance when compared with ethylene oxide sterilization method. The advantage of gamma irradiation is that it has a high penetration capacity which allows the direct sterilization of the sample when it is packed. However, gamma irradiation affects  , usually decreasing its value. In our case

, usually decreasing its value. In our case  decreased, but the mechanical properties were not affected (Table 2), because some mechanical properties do not change above a critical

decreased, but the mechanical properties were not affected (Table 2), because some mechanical properties do not change above a critical  value (Lautenschlager et al., 1986). For example in the case of tensile properties the critical value is 1.5x105 Daltons which is below of the

value (Lautenschlager et al., 1986). For example in the case of tensile properties the critical value is 1.5x105 Daltons which is below of the  of the irradiated beads. The sterilization with ethylene oxide is widely used since it does not affect

of the irradiated beads. The sterilization with ethylene oxide is widely used since it does not affect  , but it has the inconvenience that the ethylene oxide is a toxic agent, flammable and explosive and it is necessary to have a good control when using it and the amount of residual ethylene oxide in the beads should be under norm. By comparing the elastic modulus and flexural resistance reported by other commercial cements (Table 4) with the values obtained in this work we can conclude that they are in good agreement. On the other hand compression resistance was not modified by the irradiation procedure and its value is higher than 70 MPa, which is much higher than the minimum accepted by ISO 5833 norm.

, but it has the inconvenience that the ethylene oxide is a toxic agent, flammable and explosive and it is necessary to have a good control when using it and the amount of residual ethylene oxide in the beads should be under norm. By comparing the elastic modulus and flexural resistance reported by other commercial cements (Table 4) with the values obtained in this work we can conclude that they are in good agreement. On the other hand compression resistance was not modified by the irradiation procedure and its value is higher than 70 MPa, which is much higher than the minimum accepted by ISO 5833 norm.

Finally, the molecular weight of the beads was not affected when sterilized with ethylene oxide, but there is a decrement on  when gamma irradiation is used; however,

when gamma irradiation is used; however,  is within the reported values of other commercial cements treated with the same type of irradiation. Furthermore, flexural modulus, flexural resistance and compression strength are not affected by the sterilization conditions used in this work. Due to these reasons, it is possible to state that either of the sterilization methods proposed can be used when the Bonacryl cement is prepared from the beads used in this work.

is within the reported values of other commercial cements treated with the same type of irradiation. Furthermore, flexural modulus, flexural resistance and compression strength are not affected by the sterilization conditions used in this work. Due to these reasons, it is possible to state that either of the sterilization methods proposed can be used when the Bonacryl cement is prepared from the beads used in this work.

Table 3. Weight average molecular weight ( ) of commercial bone cement

) of commercial bone cement

SP*: Sterilization Process. GR: Gamma Radiation, EO: Ethylene Oxide

Table 4. Flexural Properties (3-Point Bending) of commercial bone cements.

IV. CONCLUSIONS

Molecular weight of the beads, beads size distribution and residual peroxide of the Bonacryl cement resulted adequate, since they permitted an easy manipulation of the cement formulation. The setting time, maximum temperature and mechanical properties were also in accordance with the international standard. Quasi-static mechanical properties (bending and compression strength) were not affected by the sterilization process applied. Furthermore, either of the sterilization methods can be used. However, because the cement will be used under cyclic loads, other important mechanical properties such as dynamical properties should be studied.

REFERENCES

1. Charnley, J., Acrylic Cement in Orthopaedic Surgery, E.S., Livingston, London (1970). [ Links ]

2. Graham, J., L. Pruitt, M. Ries and N. Gundiah, "Fracture and fatigue properties of acrylic bone cements. The effects of mixing method, sterilization treatment, and molecular weight." Journal of arthroplasty, 15, 1028-1035 (2000). [ Links ]

3. Haas, S.S., G.M. Brauer and G. Dickson, "A Characterization of polymethylmethacrylate bone cement", Bone Joint Surg., 57A, 380-391 (1975). [ Links ]

4. Hansen, D. and J.S. Jensen, "Additional mechanical test of bone cements", Acta Orthop Belg., 58, 268-271 (1992). [ Links ]

5. Harper, E.L., Development and characterisation of a hydroxyapatite reinforced poly(ethylmethacrylate) bone cement, PhD Thesis, London University (1996). [ Links ]

6. Horowitz, S.S., S.B. Doty, J.M. Lane and A.H. Burstein, "Studies of the mechanical failure of polymethy-methacrylate leads to bone resorption", J. Bone Joint Surg., 75A, 802-813 (1993). [ Links ]

7. ISO 5833-2002. International Standard, Implants for Surgery-Acrylic Resin Cements ( 2002). [ Links ]

8. Khorosani, S.N., Development and characterization of novel rubber thoughened bone cements, PhD Thesis, London University (1991). [ Links ]

9. Kühn, K.D., Bone Cements: Up-to-date Comparison of Physical and Chemical Properties of Commercial Materials, Springer-Verlag, Berlin (2000). [ Links ]

10. Lautenschlager, E.P., S.I. Stupp and J.C. Keller, "Structure and Properties of Acrylic Bone Cement", Functional Behaviour of Orthopaedic Biomaterials, Eds. P. Ducheyne y G.W Hastings, CRC Press Boca Raton, Florida (1986). [ Links ]

11. Lewis, G. "Properties of Acrylic Bone cements: State of the Art Review". J. Biomed Mater Res (Appl Biomater), 38, 155-182 (1997). [ Links ]

12. Morejón, L., "Homologation report of the Cuban Bone Cement Bonacryl", CCEEM, Center of Biomaterials, University of Havana, Cuba (1995). [ Links ]

13. Owen, A.B. and P.W. Beaumont, "Fracture behavior of commercial surgical acrylic bone cements", J. Biomed. Eng., 1, 277-280 (1979). [ Links ]

14. O'Rourke Muisener, P.A., L. Clayton, J. D'Angelo, J.P. Harmon, A.K. Sikder, A. Kumar, A.M. Cassell and M. Meyyappan, "Effects of gamma radiation on poly(methyl methacrylate)/single-wall nanotube composites", J. Mater. Res., 17, 2507-2512 (2002). [ Links ]

15. Taitsman, J.P. and S. Saha, "Tensile strength of wire-reinforced bone cement and twisted stainless-steel wire", J. Bone Joint Surg., 59-A, 419-425 (1977). [ Links ]

16. Topoleski, L.D.T., P. Ducheyne and J.M. Cuckler, "Microstructural pathway of fracture in poly (methylmethacrylate) bone cement failure mechanisms", J. Biomed Mater. Res., 24, 135-154 (1990). [ Links ]

17. Topoleski, L.D.T., P. Ducheyne and J.M. Cuckler, "Microstructural pathway of fracture in poly (methylmethacrylate) bone cement", Biomaterials, 14, 1165-1172 (1993). [ Links ]

18. Vila, M.M., Optimización de la fijación prótesis-hueso en implantes articulares cementados, PhD Thesis, Polytechnic University of Catalonia (1992). [ Links ]

19. Willert, H.G, H. Bertram and G.H. Buchhorn, "Osteolysis in alloarthroplasty of the hip. The role of bone cement fragmentation", Clin. Orthp. Rel. Res., 258, 108-121 (1990). [ Links ]

Received: December 1, 2006.

Accepted: September 25, 2007.

Recommended by Subject Editor Orlando Alfano.