Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Latin American applied research

versão impressa ISSN 0327-0793

Lat. Am. appl. res. v.38 n.3 Bahía Blanca jul. 2008

Application of genetic algorithms for designing cost optimal heat exchanger networks

F. B. Avila-Díaz1, A. Uribe-Rodríguez2 and E. F. Castillo-Monroy3

1 Escuela de Ingeniería Química, Universidad Industrial de Santander, Bucaramanga, Colombia.

2 Instituto Colombiano del Petróleo (ICP), Bucaramanga, Colombia. ariel.uribe@ecopetrol.com.co

3 Centro de Investigación de la Caña de Azúcar de Colombia, Cali, Colombia. efcastillo@cenicana.org

Abstract — Genetic Algorithms (GA) were implemented in a synthesis design procedure for cost optimal Heat Exchanger Networks (HEN). The procedure consisted of two coupled GAs: External GA to search the optimal HEN structure, and Internal GA to search the optimal split-fractions for each evaluated HEN structure. This design procedure was tested with five HEN synthesis cases; the configurations obtained were compared with other design procedures such as Pinch Method, Mathematical Programming (LP, MILP, MINLP and NLP models) and Stochastic methods (Genetics Algorithms, Tabu Search and Particle Swarm Optimization). In the cases 1 to 4, the ΔTmin value was taken from previous papers. In case 5 the ΔTmin value was optimized using a supertargeting routine available in the design algorithm proposed in this work. User-defined forbidden/desired matches can be easily implemented as target in the HEN design.

Keywords — Heat-Exchanger Network (HEN). Design Synthesis. Stochastic Optimization. Genetic Algorithms.

I. INTRODUCTION

Heat Exchanger Networks (HEN) are one of the most important components in chemical processes. In most cases, the HEN design determines energy efficiency of processes. A HEN consists of a group of cold streams exchanging heat with a group of hot streams. A cold stream is defined as a stream that has to be heated from a supply temperature to a higher final target temperature at which this stream is required for further stages in the process. On the other hand, a hot stream is defined as a stream that has to be cooled from a supply temperature to lower final target temperature (Biegler et al., 1997).

The synthesis design problem analyzed in this paper is determining the optimal cost HEN structure required to take all process streams from their supply temperatures to their target temperatures.

There are three different synthesis approaches to solve this problem: Mathematical programming (Soršak and Kravanja, 2004; Biegler et al., 1997; Zhu, 1997), thermodynamic (Linnhoff and Hindmarsh, 1983; Gundersen and Naess, 1988) and stochastic methods (Lin and Miller, 2004; Lewin et al., 1998; Lewin, 1998). In this work a stochastic approach, Genetic Algorithms, is applied to design Cost Optimal HENs.

GAs are iterative and stochastic procedures, which attempt to emulate the evolution given in nature by applying genetic principles on a group of individuals. Each individual represents a potential solution to the problem. An encoding - decoding method has to be defined for each type of problem; usually, the encoded individual is a string of characters. Each encoded individual must represent one, and only one, potential solution. The initial population of individuals (possible solutions) is created randomly; each individual is evaluated by a fitness function (related to the objective function in the classical optimization approach); the result of this evaluation is the quantitative performance used by the GA to guide the search through the application of genetic operators. As a result, individuals evolve, improving the fitness value (Goldberg, 1989).

GAs performance is not affected by the problem of existence of the objective function derivative or badly behaved objective function surface. GAs are very useful when the behavior of the objective function is very noisy because sub-optimal solutions are not difficult to overcome with this technique. Since GAs examine several points (individuals) in each iteration (generation), good regions instead of good points are found in the search space (Goldberg, 1989). GAs have been previously applied to many fields including communication network design and decoding of LDPC codes (Scandurra et al., 2006).

Nowadays, when faster machines are being available in the market at low cost, the computation resources required by GAs are easily fulfilled.

II. SYNTHESIS DESIGN ALGORITHM

The synthesis procedure used in this paper for designing cost optimal HENs consisted of two coupled GAs: External GA to search the optimal HEN structure, and Internal GA to search the optimal split-fraction vector for each evaluated HEN structure.

Only one type of cold utility and one type of hot utility are considered by the synthesis design procedure used here. Each stream was allowed to split in a maximum of two branches. Pipe costs are not taken into account.

The cost law for individual installed heat exchanger is shown in Eq. 1.

Cexchanger = FC + CASm, (1)

where Cexchanger is the present capital cost of each installed exchanger [US$], FC is the fixed charge [US$], S is the heat exchanger area [m2], CA is a cost coefficient per unit area [US$·m-2], and m is the power for the area. For the calculation of the annualized capital costs, the cost law should be accompanied by other data such as expected lifetime [yr] and annual interest rate. In some cases the terms of the cost law are given for obtaining an already annualized cost (expected lifetime = 1 yr.).

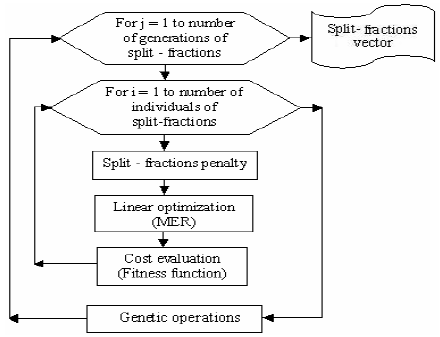

The design algorithm is shown in Fig. 1, and Fig. 2. This algorithm was implemented in MATLAB using Excelink for data exchange between Excel and Matlab.

The initial data required by the design algorithm are: Number of hot streams, number of cold streams; supply and target temperatures, heat capacity flow rate (CP) and average individual heat-transfer coefficients (h) for each stream; supply and target temperatures and

Figure 1. General design algorithm

Figure 2. Internal GA loops

average individual heat-transfer coefficients (h) for hot and cold utilities; cost law, expected life [yr] and annual interest rate for heat exchangers, heaters and coolers and finally, the cost of hot and cold utilities [US$/kW].

The algorithm includes a supertargeting procedure (Ahmad and Linnhoff, 1989), which calculates an optimal minimum difference of temperature in the heat exchangers (ΔTmin). However, for the sake of comparison, in the cases 1 to 4, the ΔTmin value was taken from previous papers. In the case 5 the ΔTmin value was optimized using the supertargeting routine previously mentioned and results were compared with previous papers where the ΔTmin value was also optimized. The initial population of HEN structures is randomly created before the GA starts the search of the best cost-optimum networks.

The routine called Preprocess verifies and corrects the structures for a maximum of two branches in each stream. This routine also rules out the heat exchanges thermodynamically forbidden (hot stream at a supply temperature lower than the supply temperature of cold stream) or the heat exchanges forbidden by the user (due to the distance between the hot and cold streams or to industrial safety reasons). In all the synthesis cases, thermodynamic forbidden exchanges were restricted; in case 3, both thermodynamic and user-defined forbidden matches were restricted.

In each HEN evaluated, the stream-split optimization problem turns out to be multimodal and non-convex, and thus requires some attention to ensure robustness. Care is needed for small values of split fractions, which can cause singularities and ill-conditioning in the LP formulation (Lewin, 1998). To avoid this problem in the internal GA, the routine called split-fraction penalty transforms fractions lower than 0.05 in zero and fractions greater than 0.95 in 1.

The linear optimization stage (MER: Maximum Energy Recovery) maximizes the sum of exchanger duties. This is equivalent to minimize the sum of heater and cooler loads (total use of utilities). A typical HEN structure is shown in Fig. 3; the linear model of optimization solved by the MER routine applied to this case is shown in Eq. 2-5.

Figure 3. Typical HEN structure

Once the duties Xi [kW] of every heat exchanger in the HEN are obtained by the MER routine, it is possible to proceed to the cost evaluation stage. This stage consists of the calculation of the total annualized cost [US$·yr-1] for each HEN structure as the sum of total annualized capital cost and total annualized operational cost.

| (2) |

subject to

Energy balances for each stream, for example H1:

| (3) |

And two thermodynamic restrictions for each exchanger (one at each side), for example X1:

| Cold Side: |  | (4) |

| Hot Side: |  | (5) |

The total annualized capital cost [US$·yr-1] is the sum of annualized capital costs for all heat exchangers in the HEN. This calculation requires the area of each exchanger [m2]; this area is directly obtained from the duty (Xi) [kW] of that exchanger (Eq. 6 and 7). The Paterson approximation is used to obtain the ΔTLM [K] value (Eq. 8); ΔT1 [K] and ΔT2 [K] are the temperature differences between hot and cold streams at each side of the exchanger.

| (6) |

| (7) |

| (8) |

The annualized operational cost calculation consists of the sum of the costs of hot and cold utilities required by the HEN in one year [US$·yr-1].

Since the cost-optimal HEN is obtained from a population of HEN structures where every individual has the number of exchangers coded in the respective chromosome and the MER is calculated for all the individuals of the population, the design algorithm used in this work follows the three steps required to be classified as a sequential synthesis type (Biegler et al, 1997). This feature of the algorithm reduces the environmental impact of the designed HEN because a lower use of hot and cold utilities implies lower thermal discharges of the process, lower requirements of steam, lower requirements of fuel combustion, lower gas emissions from combustion and lower use of water for cooling.

A. Encoding Method Used for Genetic Algorithms

For the external GA, the codification for HEN structures used here was based on the codification used by Lewin et al. (1998). To explain this codification, some previous definitions are required. The "key" streams group is selected as the greater between the hot streams group and the cold streams group; when the number of hot streams and cold streams are equal, the "key" streams are the cold streams. On the other hand, a HEN level is defined as the temperature or energy interval where heat exchangers in series are not allowed in any stream. In other words, the maximum number of HEN levels is the maximum number of exchangers in series allowed for any stream. Levels are numbered from the low-energy region to the high-energy region of the HEN. Then, level 1 is always the interval of lower energy at the cold side. The chromosome is regularly a string of characters representing one individual (in this case, one HEN structure). In this particular application, the chromosome length will be equal to the product of maximum number of levels, maximum number of branches and maximum number of key streams. For all the synthesis cases treated in this paper, the maximum number of branches was two and the maximum number of levels was three, except in the synthesis case 5 where 5 levels were used. Each character of the chromosome is a "gene" and its possible values are integers in the range between zero and the maximum number of "non-key" streams.

In each level, each key stream has two positions available in the chromosome, one for each possible branch. A gene zero represents the absence of a heat exchanger. A gene having an integer value different to zero represents the presence of a heat exchanger. When a heat exchanger is present, the non-key stream involved in that heat exchange is represented by the gene integer value; while the key stream and branch involved in the same heat exchange are represented by the position of this gene in the chromosome.

An example of a chromosome is shown in Fig. 4. It represents the HEN structure shown in Fig. 3. To avoid more than two branches in any non-key stream, a maximum of two occurrences of a determined gene value (non-key stream) is allowed in each level; all the other exchanges exceeding this maximum in each level are ruled out (zero is assigned to the corresponding gene value).

In the random creation of the initial population for the external GA, the gene values are randomly generated by considering a probability of 50% for the absence of heat exchangers in every gene. However, when a heat exchanger was present, all the non-key streams had the same probability of being selected for that exchange.

The population size was 14 individuals for all the generations of the external GA. The maximum number of generations was 100.

Figure 4. Chromosome representing the HEN structure shown in Fig. 3

Binary codification was used for the internal GA. Since a maximum of two branches was allowed, only one of the two split fractions was codified for each split in the HEN structure; the second split fraction was calculated as the subtraction from the unity. Then, only one split fraction is required to describe each split in the HEN. A split - fraction was represented by a chromosome of binary genes with a length determined by the precision of the value; in all the cases, the precision used for split - fractions was two decimals. The split-fraction vector was conformed by all the split fractions required for describing all the splits in the HEN structure. The length of this vector depended on the total number of splits in the whole HEN structure.

The population size was 6 for all the generations of the internal GA. The maximum number of generations was 15.

B. Genetic Operations and parameters for GAs

The routine called "Genetic operations" used in the design algorithm (Fig 1 and 2) corresponds to four consecutive operations: Selection of parents, Crossover, Mutation and Population replacement (Goldberg, 1989).

For applying the parent selection operation is necessary to define a fitness function and a probability of selection for each individual. In this work, the fitness function is the reciprocal of the total annualized cost and the probability of selection for each individual is the ratio of its fitness value over the sum of fitness values of all the individuals in the population.

For the external GA, two techniques of parent selection were applied: Roulette and Tournaments. Roulette consists of randomly selecting each parent from individuals of the entire population by considering their pro-bability of selection. Tournaments consists of randomly picking a subgroup of individuals out by considering an equal probability; then, among the individuals of this subgroup, one parent is randomly selected by considering the real probability of selection for each individual in this subgroup; in this work, even the size of the tournament subgroups was selected randomly in the range between two and the maximum number of individuals of the entire population. The selection of parents by roulette or tournaments is applied up to the number of selected parents is equal to the number of individuals in the current population. For the internal GA, only Roulette was applied as the parent selection technique.

In the crossover operation, a pair of individuals is randomly chosen among the previously selected parents. These two chosen parents will generate two descendants. According to a crossover probability defined by the user (px), the two descendants will be generated by combining the genetic information of the parents or by cloning the chromosomes of the parents; a constant crossover probability of 0.6 was used for both the external and the internal GAs; this crossover probability indicates that 60% of the descendants will be generated by combining the genetic information of the parents and 40% of the descendants will be generated by cloning the chromosomes of the parents. When a combination of genetic information is carried out, the two new chromosomes (two new descendants) are generated by exchanging genes between the parent chromosomes. In this work, two types of crossover were used: one-point crossover and uniform crossover. For the external GA, one-point crossover was used; in this type of crossover, the chromosome of each parent is divided in two sub-strings of genes; the position in the chromosome used as the limit between those two sub-strings is chosen randomly; the chromosome of the first descendant is generated by combining the first sub-string of the first parent with the second sub-string of the second parent; the second descendant is generated by combining the first sub-string of the second parent with the second sub-string of the first parent. For the internal GA, uniform crossover was used; in this type of crossover, the chromosome of a descendant is generated by alternatively concatenating, gene by gene, the chromosomes of the chosen parents; the first descendant will be generated when the first parent is the source of the first gene and the second descendant will be generated when the second parent is the source of the first gene.

In the mutation operation, a pair of individuals is randomly chosen among all the descendants obtained by crossover. The gene values of the two chromosomes are randomly changed according to a mutation rate. A mutation rate of 0.01 indicates that 1% of all the gene values in these two chromosomes will be changed. The mutation rate used in this paper was variable, generation after generation, at the beginning of both external and internal genetic algorithms (Fig. 5); initially, a very high mutation rate was used to guarantee a broad exploration of the search space. The highest initial value for the mutation rate was 0.8 for both external and internal GAs; the lowest value was 0.01 for external GA and 0.15 for internal GA; the value of the point X (Fig. 5) is 25 generations for external GA and 7 generations for internal GA.

The population replacement operation is the generational renovation required for evolution. For the external GA, three types of population replacement were used: Total replacement, Elitism replacement and Hybrid replacement. Total replacement is simply the substitution of all individuals from the previous generation for the descendants obtained after crossover and mutation. Elitism replacement allows the simultaneous competition between parent and descendants; the parent selection (before crossover and mutation) is done from a temporary population conformed by the population of the

Figure 5. Variable mutation rate

current generation and the population from the previous generation. Hybrid replacement operates very similar to Total replacement, with the difference that the presence of the best individuals from the current generation is guaranteed in the next generation; when this type of population replacement was used, the number of best individuals cloned into the next generation was 4 in all the cases. For the internal GA only the Hybrid replacement of population was applied.

III. HEN SYNTHESIS CASES AND RESULTS

In all the synthesis cases, tables are used to present the required initial data and the features of the reference HEN and the resulting HEN. The duties of all the process heat exchangers in the HENs are also tabulated; the order for the process heat exchangers in each table is the same order in which they occur in the chromosome string. For the sake of comparison, the annualized cost of reference HEN is re-calculated using the same routines and cost law as for the obtained HEN.

A. HEN Synthesis Case 1

This case is the Aromatics Plant problem that has been solved by Lewin (1998) applying Genetic Algorithms, by Linnhoff and Ahmad (1990) applying Thermodynamic Methods and by Zhu and O'Neill (1995) and Pettersson (2005), applying Mathematical Programming. The HEN structure obtained by Lewin (1998) was taken as the reference HEN. The cost of the resulting HEN is US$ 31614 per year less than the best solution reported by Lewin (1998) and US$ 567 per year less than the solution given by Pettersson (2005). Besides, the design obtained in this work has only two splits (H1 and H4) while the configuration obtained by Pettersson (2005) has seven splits (H1, H2, H3, H4, C1, C3 and C5). Table 4 presents the comparison of the results with these previous works.

B. HEN Synthesis Case 2

This example has been derived from the 10sp1 problem (Pho and Lapidus, 1973). This case has been solved by Flower and Linnhoff (1980), Papoulias and Grossman

Table 1. Initial data for synthesis case 1. (Lewin, 1998).

(1980), Lewin et al. (1998), Lewin (1998) and Lin and Miller (2004); applying Thermodynamic Methods,Mathematical Programming, Genetic Algorithms and Tabu Search respectively. The HEN structure obtained by Lewin et al. (1998) was taken as the reference HEN.

After applying the design algorithm proposed in this work, the resulting HEN has a cost US$ 117 per year less than the best solution reported by Lewin et al. (1998b), US$ 599 less than the best solution reported by Linnhoff and Ahmad (1990) and US$ 8 greater than the configuration obtained by Lin and Miller (2004). However, the HEN obtained by Lin and Miller (2004) has two splits with two branches and one split with three branches (See Table 8); then, Lin and Miller's HEN is a more complex design with respect to the resulting HEN in this paper and the cost difference is negligible.

C. HEN Synthesis Case 3

This problem was proposed by Nielsen et al. (1997) as a retrofit and modified by Lewin (1998) to solve a simplified grass-roots HEN design problem. In this case, besides the thermodynamic forbidden matches (H1-C5, H2-C5, H2-C6, H2-C7, H2-C8, H4-C5, H5-C5, H7-C5, H7-C6, H7-C7, H10-C5, H10-C6, H10-C7 and H10-

Table 2. Reference HEN for case 1. (Lewin, 1998).

Table 3. Resulting HEN for synthesis case 1.

Table 4. Comparison with previous papers for case 1.

Table 5. Initial data for synthesis case 2. (Lewin et al., 1998).

Table 6. Reference HEN for case 2. (Lewin et al., 1998).

Table 7. Resulting HEN for synthesis case 2.

Table 8. Comparison with previous papers for case 2.

C8), user-defined forbidden matches (H9-C3, H9-C4, H9-C5, H9-C6, H9-C7, H9-C8, H9-C9, H9-C10 and H9-C10, ) are implemented.

The forbidden matches ("bad genes") are eliminated at the preprocess stage by changing them to a zero value. In this way, only "good genes" are sent to the evolution process.

Table 9. Initial data for synthesis case 3. (Lewin, 1998).

Table 10. Reference HEN for case 3. (Lewin, 1998).

The HEN structure obtained by Lewin (1998) applying GA was taken as the reference HEN. This configuration has 31 units, including heaters and coolers and total cost of 1.61*108 DDK per year.

After applying the design algorithm presented in this work, the resulting HEN design has 27 units, QH = 42.50 MW, QC = 17.81 MW and total cost of 1.37*108 DDK per year. This HEN configuration is 17.17% per year less than the design reported by Lewin (1998).

The percentage of cost reduction with respect to the reference HEN in this case is the highest obtained when it is compared to the other cases presented in this paper, it is remarkable that this is the synthesis case with the highest number of streams.

D. HEN Synthesis Case 4

This synthesis case was solved by Zhu (1997), using block decomposition and heuristic rules. Despite the structure of the reference HEN (Zhu, 1997) and the resulting HEN is the same, the resulting HEN has a cost US$ 5443 per year less than the design reported by Zhu (1997). The cost gap is because of a better optimization of the split fraction values for the stream C1 in the resulting HEN. This synthesis case demonstrates the importance of the internal GA implemented in the design algorithm proposed in this paper.

E. HEN Synthesis Case 5

This case is a problem presented by Ahmad and Linnhoff (1989). The ΔTmin value proposed by Ahmad and Linnhoff (1989) was 10 °C. This problem was also solved by Silva et al. (2005), applying PSO and by Ravagnani et al. (2005), using GAs. Silva et al. (2005)

Table 11. Resulting HEN for synthesis case 3.

Table 12. Initial data for synthesis case 4. (Zhu, 1997).

Table 13. Reference HEN for case 4. (Zhu, 1997).

Table 14. Resulting HEN for synthesis case 4.

Table 15. Comparison with previous work for case 4.

Table 16. Initial data for synthesis case 5.

calculated an optimum ΔTmin value of 22°C, meanwhile Ravagnani et al. (2005) found 24 °C as the optimum ΔTmin value.

Applying the supertargeting procedure included in the design algorithm presented in this work, the optimum ΔTmin found was 22 °C. See Fig. 6. It is the same value reported by Silva et al. (2005). The obtained HEN cost is US$ 27768 per year less than the design reported by Ravagnani et al. (2005).

III. CONCLUSIONS

The resulting HENs obtained, after applying the design algorithm proposed in this paper, have a cost significantly lower than previously published works. It is remarkable that for the synthesis case with a greater number of streams (case 3), a greater gap between the cost obtained in this work and the cost of the reference HEN is observed in terms of cost percent. The importance of the internal GA for the optimization of the split-fraction values was demonstrated in synthesis case 4, where despite the structure of the reference HEN and the resulting HEN is the same, the resulting HEN has a cost US$ 5443 per year less than the reference HEN, this cost gap is because of a better optimization of the split fraction values in the resulting HEN. The performance of the external genetic algorithm was tested and best results were obtained when the parent selection technique was Tournaments and the generational renovation technique was Hybridreplacement. The supertargeting procedure included in the design algorithm presented in this paper produces optimum ΔTmin values similar to the optimum ΔTmin values obtained by previous authors.

Table 17. Resulting HEN for synthesis case 5.

(*) For this case, 5 HEN levels were required.

Table 18. Comparison with previous papers for case 5.

Figure 6. Supertargeting results for case 5

REFERENCES

1. Ahmad, S. and B. Linnhoff, "SUPERTARGETING: Different Process Structures for Different Economics", J. Energy Resources Tech., 111, 131-136 (1989). [ Links ]

2. Biegler, L., I. Grossman and A. Westerberg, A. Systematic Methods of Chemical Processing Design, Prentice-Hall, New Jersey (1997). [ Links ]

3. Flower, J.R. and B. Linnhoff, "A Thermodynamic Combinatorial Approach to the Design of Optimum Heat Exchangers Networks", AIChE Journal, 26, 1-9 (1980). [ Links ]

4. Goldberg, D., Genetic Algorithms in Search, Optimization, and Machine Learning, Addison Wesley Longman, New York (1989). [ Links ]

5. Gundersen, T. and L. Naess, "The Synthesis of Cost Optimal Heat Exchanger Networks. An Industrial Review of State of the Art", Comput. Chem. Eng., 12, 503-530 (1988). [ Links ]

6. Lewin, D.R., H. Wang and S. Ofir, "A Generalized Method for HEN Synthesis using stochastic optimization - I. General Framework and MER Optimal Synthesis", Comput. Chem. Eng., 22, 1503-1513 (1998). [ Links ]

7. Lewin, D.R., "A Generalized Method for HEN Synthesis using stochastic optimization - II. The Synthesis of Cost Optimal Networks", Comput. Chem. Eng., 22, 1387-1405 (1998). [ Links ]

8. Lin, B. and D.C. Miller, "Solving heat exchanger network synthesis problems with Tabu Search", Comput. Chem. Eng., 28, 1451-1464 (2004). [ Links ]

9. Linnhoff, B. and S. Ahmad, "Cost Optimum Exchanger Networks: I - Minimum Energy and Capital Using Simple Models for Capital", Comput. Chem. Eng., 14, 729-750 (1990). [ Links ]

10. Linnhoff, B. and E. Hindmarsh, "The Pinch Design Method for Heat Exchanger Networks", Chem. Eng. Sci., 38, 745-763 (1983). [ Links ]

11. Nielsen, J.S., M.W. Hansen and K.P. Kristensen, "Retrofit and Optimization of Industrial Heat Exchangers Networks: A Complete Benchmark Problem", Comput. Chem. Eng., 21, S469 - S472. (1997). [ Links ]

12. Papoulias, S.A. and I.E. Grossmann, "A Structural Optimization Approach in Process Synthesis - II Heat Recovery Networks", Comput. Chem. Eng., 7, 707-721 (1983). [ Links ]

13. Pettersson, F, "Synthesis of large-scale heat exchanger networks using a sequential match reduction approach", Comput. Chem. Eng., 29, 993-1007. (2005). [ Links ]

14. Pho, T.K. and L. Lapidus, "Topics in Computer Aided Design: Part II Synthesis of Optimal Heat Exchangers Networks by Tree Searching Algorithms", AIChE Journal, 19, 1182-1189 (1973). [ Links ]

15. Ravagnani, M.A.S.S, A.P. Silva, P.A. Arroyo and A.A. Constantino, "Heat Exchanger Network Synthesis and Optimization Using Genetic Algorithm", App. Thermal Eng., 25, 1003 -1017. (2005). [ Links ]

16. Scandurra, A.G., A.L. Dai Pra, L. Arnone, L. Passoni and J. Castineira Moreira, "A genetic-algorithm based decoder for low density parity check codes", Lat. Am. Appl. Res., 36, 169-173 (2006). [ Links ]

17. Silva, A.P., E.C. Biscaia and M.A.S.S. Ravagnani, "Heuristic Optimization of Heat Exchanger Networks", 4th Mercosur Congress on Process Systems Engineering, Costa Verde RJ, Brazil. (2005). [ Links ]

18. Sorsak, A. and Z. Kravanja, "MINLP retrofit of heat exchanger networks comprising different exchanger types", Comput. Chem. Eng., 28, 235-251 (2004). [ Links ]

19. Zhu, X., "Automated Design Method for Heat Exchanger Network Using Block Decomposition and Heuristic Rules", Comput. Chem. Eng., 21, 1095-1104 (1997). [ Links ]

20. Zhu, X. and B. O'Neill, "A Method for Automated Heat Exchanger Network Synthesis Using Block Decomposition and Non-Linear Optimization", Trans. I. ChemE. part A, 73, 919-930 (1995). [ Links ]

Received: February 20, 2007.

Accepted: November 18, 2007.

Recommended by Subject Editor José Pinto.