Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Latin American applied research

Print version ISSN 0327-0793

Lat. Am. appl. res. vol.40 no.1 Bahía Blanca Jan. 2010

ARTICLES

Osmotic dehydration of button mushroom: Fickian diffusion in slab configuration

M. E. Rezagah, M. Kashaninejad, H. Mirzaei and M. Khomeiri

Department of Food Science and Technology, Gorgan University of Agricultural Sciences and Natural Resources, Beheshti Avenue, Gorgan 49138-15739, Iran. m_rezagah@yahoo.com, kashani@gau.ac.ir, habibmirzaei@yahoo.ca, khomeiri@gau.ac.ir

Abstract Osmotic dehydration is a method to partially remove moisture from vegetables and fruits. Three sucrose concentrations (20, 30 and 40% w/w) in four temperatures (30, 40, 50 and 60ºC) were used in this study. Effective diffusion coefficient was determined for examined temperatures and concentrations using Fick's second law of diffusion adapted to slab geometry. The calculated effective diffusion coefficients of water were of the order of 10-9 m2/s. Activation energy was calculated and found to be 17.533, 4.861 and 5.446kJ/mol for 20, 30 and 40% w/w solutions, respectively.

Keywords Osmotic Dehydration; Button Mushroom; Effective Diffusion Coefficient; Activation Energy.

I. INTRODUCTION

Mushrooms are edible fungi of commercial importance and their cultivation has emerged as a promising agro-based land-independent enterprise (Shivhare et al., 2004). Consumption of mushrooms has increased substantially due to their nutritional value, delicacy and flavor. Button mushroom (Agaricus bisporus) is the most widely cultivated and consumed mushroom throughout the world and it contributes about 40% of the total world production of mushroom (Giri and Prasad, 2007) but due to very short shelf life of fresh mushroom using preservation methods to extend the shelf life is recommended. Drying is the easiest means to increase the longevity of high moisture products (Shukla and Singh, 2007). On the other hand mushrooms are very sensitive to temperature, therefore choosing a proper method of drying is a very important decision.

Osmotic dehydration is widely used for partial removal of water from product by immersion of mushroom in a hypertonic solution. The deriving force for the diffusion of water from the tissue into the solution is provided by the higher osmotic pressure of the hypertonic solution (Rastogi and Raghavarao, 2004). Simultaneously some of the solute diffuses into the tissue. The rate of diffusion of water depends on temperature, concentration of osmotic solution, material to solution mass ratio, size and geometry of the material.

Knowledge of drying kinetics of biological materials is essential to design, optimization and control of the drying process. Several studies have been carried out to determine osmotic drying behavior of plants (Ade-Omowaye et al., 2002; Azuara and Beristain, 2002; Corzo and Bracho, 2006; El-Aouar et al., 2003; Rahimzade Khoyi and Hesari, 2007; Rastogi and Raghavarao, 2004; Sutar and Gupta, 2007) and some on drying behavior of mushrooms (Arora et al., 2003; Giri and Prasad, 2007; Sahbaz et al., 2000; Walde et al., 2006), but there is a lack of such studies on osmotic dehydration of button mushrooms. Therefore, the present study wishes to determine the effect of osmotic solution concentration and temperature on drying kinetics during osmotic dehydration of button mushrooms and to calculate the effective diffusion coefficient and activation energy of the samples in different situations of osmotic dehydration.

II. MATERIALS AND METHODS

A. Materials

Fresh button mushrooms were obtained daily from local market and before each test the mushrooms were sorted according to their size and maturity, washed to remove dirt and sliced with a sharp knife. Slices of 5mm thickness were then blanched in boiling water for 1 minute to inactive enzymes responsible for enzymatic browning. Initial moisture content was measured at 103±2ºC. Commercial sucrose was used as the osmotic agent.

B. Osmotic dehydration

Prior to starting osmotic dehydration of mushroom in osmotic solution, the slices were blotted with tissue paper to remove excess moisture from the surface. Osmotic solution was prepared (20, 30 and 40%w/w concentrations). A hot water bath was used to keep osmotic dehydration at desired temperatures (30, 40, 50 and 60ºC). The mass ratio of slices to osmotic solution was maintained at 1:25 in order to ensure that the concentration of the osmotic solution did not change significantly during the experiment (Rastogi and Raghavarao, 2004).

Observations were taken at intervals of 15 minutes for the first hour, followed by intervals of 30 minutes for the next 2 hours and two final measurements with intervals of 60 minutes. Therefore, total process time for osmotic dehydration was 5 hours.

C. Calculations

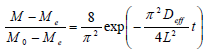

Solution of Fick's second law of diffusion assuming mushroom slices to be a flat plate results the following equation for diffusion of moisture through the material to the surface (Azoubel et al., 2002):

| (1) |

where:

M: Moisture content (kg/kg dry matter)

t: Time (s)

Deff: Water effective diffusion coefficient (m2/s)

Me: Equilibrium moisture content (kg/kg dry matter)

Mo: Initial moisture content (kg/kg dry matter)

L: Thickness of the slice when mass transfer occurs on one side of the slice (m)

For long drying times Eq.1 can be reduced to the following equation:

| (2) |

which can be written as:

| (3) |

And the effective diffusion coefficient, Deff, can be measured from the slope of the plot of  against time.

against time.

The temperature dependency of effective diffusion coefficient may be used to calculate the activation energy for drying. Arrhenius-type equation was used for this purpose, as described by Eq.4.

| (4) |

where:

Ea: Activation energy (kJ/mol)

A: Constant

R: Universal gas constant (kJ/mol K)

T: Absolute temperature (K)

Other form of Eq. 4 (shown in Eq. 5) can be used to calculate activation energy from plot of lnDeff against 1/T.

| (5) |

III. RESULTS AND DISCUSSION

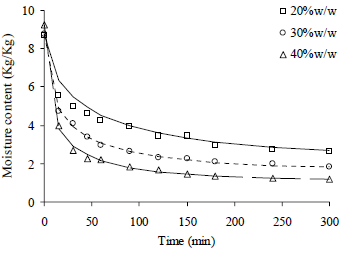

Results for changes of moisture content (d.b) against time for temperatures from 30 to 60ºC are shown in Fig. 1 to Fig. 4, respectively. Predicted moisture content using Page's model is also shown.

Figure 1. Changes of moisture content during osmotic dehydration of button mushroom at 30ºC

Figure 2. Changes of moisture content during osmotic dehydration of button mushroom at 40ºC

Figure 3. Changes of moisture content during osmotic dehydration of button mushroom at 50ºC

Figure 4. Changes of moisture content during osmotic dehydration of button mushroom at 60ºC

It is obvious that most of the moisture loss occurs in the first hour of the process. At this time osmotic pressure difference, which is the deriving force of mass transfer, between mushroom tissue and osmotic solution is higher. Same results were obtained by Ade-Omowaye et al. (2002), Azoubel et al. (2002), El-Aouar et al. (2003), Rahimzade Khoyi and Hesari (2007) and Torringa et al. (2001) for different fruits and vegetables.

Results of effective diffusion coefficient, obtained from plots of ln(MR) against time, are shown in Table 1. Effective diffusion coefficient increased with the increasing of osmotic solution concentration in all examined temperatures.

Table 1. Effective diffusion coefficient of mushroom

This shows that higher concentration causes more water to be removed from the mushroom tissue. Effective diffusion coefficients were found to be in the same range with results of Jambark et al. (2007) for drying of button mushroom accelerated by power ultrasound. Their results showed that effective diffusion coefficient is in the range of 1.6x10-9 to 2.28x10-9m2/s.

Results for activation energy (Table 2) represent that more energy is needed to initiate the removal of water from mushroom slices using 20%w/w osmotic solution. But activation energy using 30 and 40% w/w osmotic solution are very close. Slightly higher activation energy using 40% w/w osmotic solution might be due to less R2. Sahbaz et al. (2000) reported that activation energy for drying of button mushroom without blanching pretreatment is in the range of 23.2-34 kJ/mol and for drying of mushroom with blanching pretreatment is in the range of 13.4-23kJ/mol. So it is obvious that higher concentrations (30 and 40%w/w) can be recommended to remove moisture from mushroom slices.

Table 2. Activation energy in different temperatures

IV. CONCLUSIONS

Osmotic dehydration of sliced button mushroom was studied. It was found that moisture content reduces during osmotic dehydration. It is also obvious that more loss of water occurs in solutions with higher concentrations. Results of effective diffusion coefficient in different temperatures and concentrations confirm the effect of temperature and concentration of osmotic solution. Effective diffusion coefficient increased with increasing of temperature and concentration.

AKNOWLEDGMENTS

Authors wish to thank Dr. Mona Hourvash from Shiraz University, Shiraz, Iran, for her helpful comments which improved the quality and readability of the paper.

REFERENCES

1. Ade-Omowaye, B.I.O., N.K. Rastogi, A. Angersbach and D. Knorr, "Osmotic dehydration behavior of red paprika (Capsicum annuum L.)", Journal of Food Science, 67, 1790-1796 (2002). [ Links ]

2. Arora, S., U.S. Shivhare, J. Ahmed and G.S.V. Raghavan, "Drying kinetics of Agaricus bisporus and Pleurotus florida mushrooms", Transactions of the ASAE, 46, 721-724 (2003). [ Links ]

3. Azoubel, P.M., R.V. Tonon and F.E.X. Murr, "Effect of osmotic dehydration in sucrose solution in the drying kinetics of cashew apple (Anacardium occidentale L.)", Proc. 13th International Drying Symposium, Beijing, China, 929-935 (2002). [ Links ]

4. Azuara, E. and C.I. Beristain, "Osmotic dehydration of apples by immersion in concentrated sucrose /maltodextrin solution", Journal of Food Processing Preservation, 26, 295-306 (2002). [ Links ]

5. Corzo, O. and N. Bracho, "Application of Peleg model to study mass transfer during osmotic dehydration of sardine sheets", Journal of food engineering, 75, 535-541 (2006). [ Links ]

6. El-Aouar, A.A., P.M. Azoubel and F.E.X. Murr, "Drying kinetics of fresh and osmotically pre-treated papaya (Carica papaya L.,", Journal of food engineering 59, 85-91 (2003). [ Links ]

7. Giri, S.K. and S. Prasad, "Drying kinetics and rehydration characteristics of microwave-vacuum and convective hot-air dried mushrooms", Journal of food engineering, 78, 512-521 (2007). [ Links ]

8. Jambark, A.R., T.J. Mason, L. Paniwnyk and V. Lelas, "Accelerated drying of button mushrooms, brussels sprouts and cauliflower by applying power ultrasound and its rehydration properties", Journal of Food Engineering, 81, 88-97 (2007). [ Links ]

9. Rahimzade Khoyi, M. and J. Hesari, "Osmotic dehydration kinetics of apricot using sucrose solution", Journal of Food Engineering, 78, 1355-1360 (2007). [ Links ]

10. Rastogi, N.K. and K.S.M.S. Raghavarao, "Mass transfer during osmotic dehydration of pineapple: considering Fickian diffusion in cubical configuration", Lebensm.-Wiss. u.-Technol, 37, 43-47 (2004). [ Links ]

11. Sahbaz, F., D. Uzman and T.K. Palazoglu, "Drying kinetics of blanched and unblanched mushrooms", Die Nahrung, 44, 283-284 (2000). [ Links ]

12. Shivhare, U.S., S. Arora, J. Ahmed and G.S.V. Raghavan, "Moisture adsorption isotherms for mushroom", Lebensm.-Wiss. u.-Technol, 37, 133-137 (2004). [ Links ]

13. Shukla, B.D. and S.P. Singh, "Osmo-convective drying of cauliflower, mushroom and greenpea", Journal of food engineering, 80, 741-747 (2007). [ Links ]

14. Sutar, P.P. and D.K. Gupta, "Mathematical modeling of mass transfer in osmotic dehydration of onion sclices", Journal of food engineering, 78, 90-97 (2007). [ Links ]

15. Torringa, E., E. Esveld, I. Scheewe, R. van den Berg and P. Bartels, "Osmotic dehydration as a pre-treatment before combined microwave-hot-air drying of mushrooms", Journal of food engineering, 49, 185-191 (2001). [ Links ]

16. Walde, S.G., V. Velu, T. Jyothirmayi and R.G. Math, "Effects of pretreatments and drying methods on dehydration of mushroom", Journal of food engineering, 74, 108-115 (2006). [ Links ]

Received: August 12, 2008.

Accepted: November 11, 2008.

Recommended by Subject Editor Ricardo Gómez.