Serviços Personalizados

Journal

Artigo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares em

SciELO

Similares em

SciELO

Compartilhar

Latin American applied research

versão On-line ISSN 1851-8796

Lat. Am. appl. res. vol.40 no.2 Bahía Blanca abr. 2010

ARTICLES

Thermophoresis and chemical reaction effects on mhd mixed convective heat and mass transfer past a porous wedge in the presence of suction

I. Muhaimin, R. Kandasamy and A. B. Kamis

Centre for Science Studies, University Tun Hussein Onn Malaysia, 86400, Parit Raja, Batu Pahat Johor, Malaysia,

Email: future990@gmail.com

Abstract - The effects of thermophoresis and MHD mixed convection flow with heat and mass transfer over a porous wedge are presented here, taking into account the homogeneous chemical reaction of first order. The governing fundamental equations are approximated by a system of nonlinear ordinary differential equations and are solved numerically by using the Runge Kutta Gill and shooting methods. The steady-state velocity, temperature and concentration profiles are shown graphically. It is observed that due to the presence of first-order chemical reaction, the concentration decreases with increasing values of the chemical reaction parameter. The results also showed that the particle deposition rates were strongly influenced by thermophoresis and the strength of the magnetic field in the presence of buoyancy force, particularly for opposing flow and hot surfaces. Numerical results for the skin-friction coefficient, wall heat and mass transfer are obtained and reported graphically for various parametric conditions to show interesting aspects of the solution.

Keywords - Chemical Reaction; Thermophoresis Particle Deposition and Magnetic Effect.

I. INTRODUCTION

Thermophoresis is a phenomenon, which causes small particles to be driven away from a hot surface and towards a cold one. It has also been shown that thermophoresis is the dominant mass transfer mechanism in the modified chemical vapor deposition process used in the fabrication of optical fiber perform and is also important in view of its relevance to postulated accidents by radioactive particle deposition in nuclear reactors. In the application of pigments, or chemical coating of metals, or removal of particles from a gas or liquid stream by filtration, there can be distinct advantages in exploiting deposition mechanisms to improve efficiency.

Goldsmith and May (1966) first studied the thermophoretic transport involved in a simple one-dimensional flow for the measurement of the thermophoretic velocity. Thermophoresis in laminar flow over a horizontal flat plate has been studied theoretically by Goren (1977). Thermophoresis in natural convection with variable properties for a laminar flow over a cold vertical flat plate has been studied by Jayaraj et al. (1999). Selim et al. (2001) studied the effect of surface mass flux on mixed convective flow past a heated vertical flat permeable plate with thermophoresis. The first analysis of thermophoretic deposition in geometry of engineering interest appears to be that of Hales et al. (1972). They have solved the laminar boundary layer equations for simultaneous aerosol and steam transport to an isothermal vertical surface situated adjacent to a large body of an otherwise quiescent air-steam-aerosol mixture. Recently, Chamkha and Pop (2004) studied the effect of thermophoresis particle deposition in free convection boundary layer from a vertical flat plate embedded in a porous medium.

Transport processes in porous media play a significant roles in various applications such as in geothermal engineering, thermal insulation, energy conservation, petroleum industries solid matrix heat exchangers, chemical catalytic reactors, underground disposal of nuclear waste materials and many others. In many transport processes in nature and in industrial applications in which heat and mass transfer with thermophoresis particle deposition is a consequence of buoyancy effects caused by diffusion of heat and chemical species. The study of such processes is useful for improving a number of chemical technologies, such as polymer production and food processing.

A large amount of research work has been reported in this field. In particular, the study of heat and mass transfer with chemical reaction is of considerable importance in chemical and hydrometallurgical industries. Chemical reaction effects on heat and mass transfer laminar boundary layer flow have been discussed by many authors (Hakiem et al., 1999; Kuo, 2005; Cheng and Lin, 2002; Apelblat, 1982) in various situations.

On the other hand, when a conductive fluid moves through a magnetic field, an ionized gas is electrically conductive; the fluid may be influenced by the magnetic field. Magnetohydrodynamic(MHD) mixed convection heat transfer flow in porous and non-porous media is of considerable interest in the technical field due to its frequent occurrence in industrial technology and geothermal application, high temperature plasmas applicable to nuclear fusion energy conversion, liquid metal fluids, and (MHD) power generation systems.

At present, to the author's best knowledge, two studies dealing with the thermophoresis effect in porous media were published: recently Chamkha and Pop (2004) looked to the effect of thermophoresis particle deposition in free convection boundary layer from a vertical flat plate embedded in a porous medium; the steady free convection over an isothermal vertical circular cylinder embedded in a fluid-saturated porous medium in the presence of the thermophoresis particle deposition effect was analyzed by Chamka et al. (2004). On the other hand, the impetuous research on convective flows in porous media is surveyed in the recent books by Nield and Bejan (1999) and Ingham and Pop (1998, 2002). In these types of problems, the well known Falkner-Skan transformation is used to reduce boundary-layer equations into ordinary differential equations for similar flows (Falkner and Skan, 1931). It can also be used for non-similar flows for convenience in numerical work because it reduces, even if it does not eliminate, depends on the x-coordinate. Laminar boundary layer flow over a wedge with suction/injection has been discussed by many authors (Cebeci and Bradshaw, 1984; Schlichting, 1979; Yih, 1998; Watanabe, 1990; Kafoussias and Nanousis, 1997).

Effects of heat and mass transfer on nonlinear mixed convection flow in the presence of suction / injection have been studied by many authors in different situations. But so far no attempt has been made to analyze the effects of thermophoresis particle deposition with chemical reaction on nonlinear MHD mixed convective heat and mass transfer past a porous wedge in the presence of suction or injection and hence we have considered the problem of this kind. The order of chemical reaction in this work is taken as first-order reaction. It is hoped that the results obtained will not only provide useful information for applications, but also serve as a complement to the previous studies.

II. MATHEMATICAL ANALYSIS

Let us consider a steady, laminar, hydro magnetic coupled heat and mass transfer by mixed convection flow in front of a stagnation point on a wedge plate embedded in porous medium. The fluid is assumed to be Newtonian and electrically conducting with constant wall temperature Tw and concentration Cw which is embedded in a fluid-saturated porous medium of ambient temperature T∞ and concentration C∞, where Tw>T∞ and Cw>C∞, respectively. The effect of thermophoresis is being taken into to help in the understanding of the mass deposition variation on the surface. The flow configuration and coordinate system are as shown in Fig. 1. A uniform transverse magnetic field of strength Bo is applied parallel to the y-axis. Fluid suction is imposed at the wedge surface, see Fig. 1. We further assume that (i) the mass flux of particles is sufficiently small so that the main stream velocity and temperature fields are not affected by the thermo physical processes experienced by the relatively small number of particles, (ii) due to the boundary layer behavior the temperature gradient in the y-direction is much larger than that in the x-direction and hence only the thermophoretic velocity component which is normal to the surface is of considerable importance, (iii) the fluid has constant kinematic viscosity and thermal diffusivity, and that the Boussinesq approximation may be adopted for steady laminar flow,(iv) the particle diffusivity is assumed to be constant, and the concentration of particles is sufficiently dilute to assume that particle coagulation in the boundary layer is negligible,(v) the magnetic Reynolds number is assumed to be small so that the induced magnetic field is negligible in comparison to the magnetic field and the chemical reaction are taking place in the flow. Under the above assumptions, the governing equations (see Selim et al., 2001) for this problem can be written as

| (1) | |

| (2) |

| (3) | |

| (3) |

Together with the Boussinesq approximation

| (5) |

where the thermophoresis deposition velocity in the y- direction is given by

| (6) |

where u, v are the velocity components in the x and y directions respectively, ν is the kinematic viscosity, g is the acceleration due to gravity, S is the electrical conductivity, ? is the density of the fluid, ß is the coefficient of thermal expansion, ß* is the coefficient of volumetric expansion, Bo is the magnetic induction, am is the thermal diffusivity of the fluid, μ is the dynamic viscosity, D is the effective diffusion coefficient, cp is the specific heat at constant pressure, k1 is the rate of chemical reaction, K is the permeability of the porous medium, O is the angle of inclination of wedge, k is the thermophoretic coefficient. The second term on the right-hand side of Eq. (3) represents viscous dissipation effect. We remark that only the velocity component given by (5) and (6) are to be considered within the boundary-layer framework. The boundary conditions are,

| (7) | |

| (8) |

Fig. 1: Flow Analysis

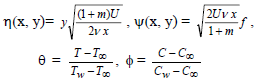

Introducing the stream function [20] ψ in the usual way, in order to identically satisfy the continuity equation, and using the dimensionless quantities

| (9) |

Under this consideration, the potential flow velocity can be written as U(x) = A xm, ![]() , where A is a constant and ß1 is the Hartree pressure gradient parameter that corresponds to

, where A is a constant and ß1 is the Hartree pressure gradient parameter that corresponds to ![]() for a total angle O of the wedge. The continuity Eq. (1) is satisfied by the stream function ψ(x, y) defined by

for a total angle O of the wedge. The continuity Eq. (1) is satisfied by the stream function ψ(x, y) defined by

| (10) |

Now the Eqs. (2) to (4) becomes

| (11) | |

| (12) |

| (13) |

The boundary conditions can be written as

| (14) |

| (15) |

where v0 is the velocity of suction if v0<0 and injection if v0>0.

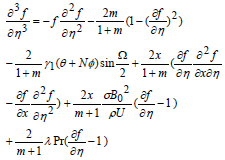

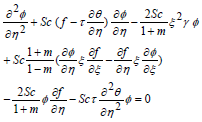

The Eqs. (11) to (13) and boundary conditions (14) and (15) can be written as

| (16) |

| (17) |

| (18) |

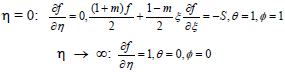

with boundary conditions

| (19) |

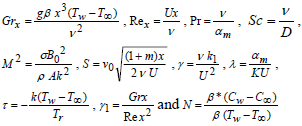

where the Grashof number Grx, the Eckert number Ec, the Reynolds number Rex, the Prandtl number Pr, the Schmidt number Sc, magnetic parameter M2, the suction parameter S, the chemical reaction parameter ?, the porous medium parameter ?, the thermophoretic parameter τ, the local buoyancy parameter ?1 and the sustentation parameter N are defined as

| (20) |

where Tr is some reference temperature and k is the thermophoretic coefficient which is defined as (see Selim et al., 2001). S is the suction parameter if S > 0 and injection if S < 0 and ?= k x(1-m)/2 (Kafoussias and Nanousis, 1997) is the dimensionless distance along the wedge (? > 0).

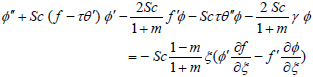

The Eqs. (16) to (18) are changed to

| (21) |

| (22) | |

| (23) |

with boundary conditions

| (24) |

The major physical quantities of interest are the local skin friction coefficient; the local Nusselt number and the local Sherwood number are defined, respectively, by:

| (25) |

The mass diffusion Eq. (23) can be adjusted to meet these circumstances if one takes ? > 0 for destructive reaction, ? = 0 for no reaction and ? < 0 for generative reaction.

III. NUMERICAL SOLUTION

The MHD boundary layer over the wedge, subjected to a velocity of suction or injection, is described by the system of partial differential Eqs. (16) - (18), and its boundary conditions (19). In this system of equations f (?,?) is the dimensionless stream function; T(?,?) be the dimensionless temperature; ![]() (?,?) be the dimensionless concentration; Pr the Prandtl number; Rex, Reynolds number, etc., which are defined in (20). It is obvious that the no similarity aspects of the problem are embodied in the terms containing partial derivatives with respect to ?. Thus, with ? derivative terms retained in the system of Eqs. (21) - (24), it is necessary to employ a numerical scheme (Gill, 1951; and Oran and Boris, 2000) suitable for partial differential equations for the solution. In addition, owing to the coupling between adjacent streamwise locations through the ?derivatives, a locally autonomous solution, at any given streamwise location, cannot be obtained.

(?,?) be the dimensionless concentration; Pr the Prandtl number; Rex, Reynolds number, etc., which are defined in (20). It is obvious that the no similarity aspects of the problem are embodied in the terms containing partial derivatives with respect to ?. Thus, with ? derivative terms retained in the system of Eqs. (21) - (24), it is necessary to employ a numerical scheme (Gill, 1951; and Oran and Boris, 2000) suitable for partial differential equations for the solution. In addition, owing to the coupling between adjacent streamwise locations through the ?derivatives, a locally autonomous solution, at any given streamwise location, cannot be obtained.

In such a case, an implicit marching numerical solution scheme is usually applied preceding the solution in the ?-direction, i.e., calculating unknown profiles at ![]() when the same profiles at

when the same profiles at ![]() are known. The process starts at ? = 0 and the solution proceeds from

are known. The process starts at ? = 0 and the solution proceeds from ![]() to

to ![]() but such a procedure is time consuming.

but such a procedure is time consuming.

However, when the terms involving ![]() ,

, ![]() and

and ![]() and their ? derivatives are deleted, the resulting system of equations resembles, in effect, a system of ordinary differential equations, for the functions f, T and

and their ? derivatives are deleted, the resulting system of equations resembles, in effect, a system of ordinary differential equations, for the functions f, T and ![]() with ? as a parameter and the computational task is simplified. Furthermore a locally autonomous solution, for any given ? can be obtained because the streamwise coupling is severed.

with ? as a parameter and the computational task is simplified. Furthermore a locally autonomous solution, for any given ? can be obtained because the streamwise coupling is severed.

So, in this work, a modified and improved numerical solution scheme, for local nonsimilarity boundary layer analysis, is used. The scheme is similar to that of Minkowycz et al. (1988) but it deals with the differential equations in lieu of integral equations. In each level of truncation, the governing coupled and nonlinear system of differential equations is solved by applying the common finite difference method, with central differencing, a tridiagonal matrix manipulation, and an iterative procedure. The whole numerical scheme can be programmed and applied easily and has distinct advantages compared to that in Minkowycz et al. (1988) with respect to stability, accuracy, and convergence speed. The details of this scheme are described in Kafoussias and Karabis (1996).

To examine the behavior of the MHD boundary layer over the wedge, numerical calculations were carried out for different values of the dimensionless parameters, entering the problem under consideration for Pr = 0.71, which corresponds to air. The numerical results are shown in Figs. 2-8 for the velocity, the temperature and the concentration of the fluid along the wall of wedge.

IV. RESULTS AND DISCUSSION

Numerical computations are carried out for 1=M2=5, 0.5=?=5.0, 0.1=?1=3.0 and 1=τ=3.0. Typical velocity, temperature and concentration profiles are shown in following Figures for Pr = 0.71 and some values for the parameters ?, M2, τ, ?1, Sc, m, N, Ec and ?. The case ?1»1.0 corresponds to pure free convection, ?1=1.0 corresponds to mixed convection and ?1«1.0 corresponds to pure forced convection. Throughout this calculation we have considered ?1=1.0 unless otherwise specified.

However, to check the present numerical results, we calculate the values of the reduced heat and mass transfer, respectively as: T ´(0), ![]() ´(0), from the vertical surface (O=90º) for ?=M2=τ =N= Ec =0, ?1=2, Sc=?=1 and m=0.333 we obtained T ´(0)=-0.443821, while the value founded by Chamkha and Pop(2004) is T ´(0)=-0.44325, and by Cheng and Minkowycz (1977) is T ´(0)=-0.4437. Also for the different parameters ?=M2=τ = Ec =0, ?1=2, N = 3, Sc = ? = 1 and m=0.333 we get T´(0)=

´(0), from the vertical surface (O=90º) for ?=M2=τ =N= Ec =0, ?1=2, Sc=?=1 and m=0.333 we obtained T ´(0)=-0.443821, while the value founded by Chamkha and Pop(2004) is T ´(0)=-0.44325, and by Cheng and Minkowycz (1977) is T ´(0)=-0.4437. Also for the different parameters ?=M2=τ = Ec =0, ?1=2, N = 3, Sc = ? = 1 and m=0.333 we get T´(0)=![]() ´(0) = -0.627889, while Chamkha and Pop(2004) obtained T´(0)=

´(0) = -0.627889, while Chamkha and Pop(2004) obtained T´(0)=![]() ´(0)=-0.62783. It can be seen these results are in excellent agreement and the present numerical results are very accurate.

´(0)=-0.62783. It can be seen these results are in excellent agreement and the present numerical results are very accurate.

In the absence of diffusion equations, in order to ascertain the accuracy of our numerical results, the present study is compared with the available exact solution in the literature. The velocity profiles for ? are compared with the available exact solution of Minkowycz et al. (1988), is shown in Fig. 2. It is observed that the agreements with the theoretical solution of velocity and temperature profiles are excellent.

Fig. 2: Comparison of the velocity and temperature profiles. with Minkowycz et al. (1988)

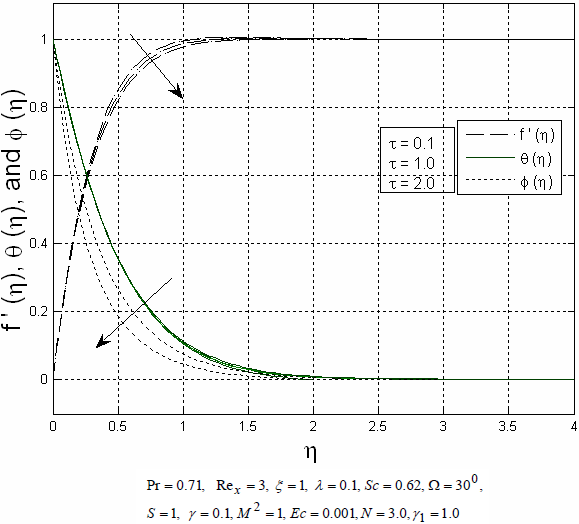

Effects of thermophoretic parameter τ on velocity, temperature and concentration field are shown in Fig. 3. It is seen that the velocity and concentration of the fluid decrease with increase of thermophoretic parameter. In particular, the effect of increasing the thermophoretic parameter τ is limited to increasing the wall slope of the concentration profiles (is shown in Table I), but decreasing the concentration. This is true only for small values of Schmidt number for which the Brownian diffusion effect is large compared to the convection effect. However, for large values of Schmidt number (Sc > 100) the diffusion effect is minimal compared to the convection effect and, therefore, the thermophoretic parameter τ is expected to alter the concentration boundary layer significantly. This is consistent with the work of Goren (1977) on thermophoresis of aerosol particles in wedge plate boundary layer.

Fig. 3: Thermophoretic effects on velocity, temperature and concentration profiles

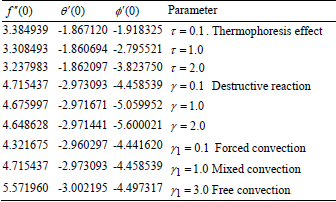

Table I: Analysis for skin friction and rate of heat and mass transfer [Angle of inclination for wedge plate is O = 30° (m=0.0909)]

Figure 4 presents typical profiles for velocity, temperature and concentration for various values of magnetic parameter, for a physical situation with uniform chemical reaction and thermophoretic effects. It is clearly shown that the velocity of the fluid increases and the temperature and concentration of the fluid slightly decrease with increase of the strength of magnetic field. The effects of a transverse magnetic field to an electrically conducting fluid gives rise to a resistive-type force called the Lorentz force. This force has the tendency to speed up the motion of the fluid. This result qualitatively agrees with the expectations, since magnetic field exerts retarding force on the mixed convection flow. Application of a magnetic field moving with the free stream has the tendency to induce a motive force which decreases the motion of the fluid and increases its boundary layer.

Fig. 4: Magnetic effect on velocity, temperature and concentration profiles

Effects of the Schmidt number on velocity, temperature and concentration profiles are shown through Fig 5. It is seen from this figure that the velocity and concentration of the fluid decrease with increase of Schmidt number, whereas the profiles for velocity temperature is not significant with increase of Schmidt number. It is clear that the concentration decreases tremendously in the presence of destructive reaction of the chemical reaction.

Fig. 5: Schmidt number effect on velocity, temperature and concentration profiles

Effects of chemical reaction with thermophoresis are very important in the concentration field. The dimensionless velocity, temperature and concentration distribution for different destructive reaction of chemical reaction is shown in Fig. 6. It is seen that the concentration of the fluid decreases with increase of destructive reaction (? > 0) whereas the velocity and temperature profiles are significant with increase of destructive reaction. Also, it is observed that the concentration of the fluid decreases uniformly near the wall of the wedge.

Fig. 6: Destructive reaction effect on velocity, temperature and concentration profiles

Figure 7 illustrates the influence of the suction parameter S on the velocity, temperature and concentration profiles, respectively. The imposition of wall fluid suction for this problem has the effect of increasing the entire hydrodynamic and reduces the thermal and concentration boundary layers causing the fluid velocity to increase while decreasing its temperature and concentration. The decreasing of thickness of the concentration layer is caused by two effects; (i) the direct action of suction, and (ii) the indirect action of suction causing a thicker thermal boundary layer, which corresponds to lower temperature gradient, a consequent increase in the thermophoretic force and higher concentration gradient.

Fig. 7: Suction effect on velocity, temperature and concentration profiles

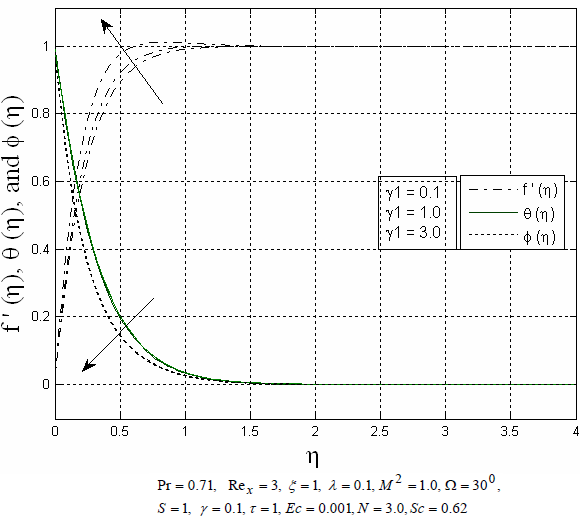

Effects of the buoyancy parameter on velocity, temperature and concentration profiles are shown through Fig. VIII. It is seen from the figure that the velocity of the fluid for free convection flow is more dominant to compare with the other convection flow whereas the temperature and concentration of the fluid are not significant with increase of ?1.

Fig. 8: Buoyancy effect on velocity, temperature and concentration profiles

From the Table I, it is observed that the rate of mass transfer decreases where as the skin friction and the rate of heat transfer are not significant with increase of thermophoresis parameter, along the wall of the wedge and the skin friction and the rate of mass transfer of the fluid along wall wedge decrease with increase of destructive reaction of the chemical reaction. It is interesting to note that the rate of heat and mass transfer for forced convection flow is more dominant to compare with free and mixed convection flow.

V. CONCLUSIONS

In this work the problem of the effects of thermophoresis and chemical reaction on MHD mixed convective heat and mass transfer past a porous wedge in the presence of suction is investigated. From the investigation, it is noticed that the increase of the strength of thermophoresis particle deposition is expected to alter the concentration boundary layer significantly. Particularly, it isseen that the rate of heat and mass transfer for forced convection flow is more dominant to compare with free and mixed convection flow. So, the increase of the strength of thermophoresis and chemical reaction with magnetic effects have a substantial effect on the flow field and, thus, on the heat and mass transfer rate from the sheet to the fluid. Thermophoresis with chemical reaction plays an important role on the rapid growth of China's economy has led to severe air pollution characterized by acid rain, severe pollution in cities, and regional air pollution. High concentrations are found for various pollutants such as sulfur dioxides (SO2), nitrogen oxides (NOx), and fine particulates. Great efforts have thus been undertaken for the control of air pollution in the country. It is hoped that the results obtained will not only provide useful information for applications, but also serve as a complement to the previous studies.

ACKNOWLEDGEMENT

The authors wish to express their cordial thanks to our beloved The Vice-Chancellor and The Director of Centre for Science Studies, UTHM Malaysia for their encouragements.

REFERENCES

1. Apelblat, A., "Mass transfer with a chemical reaction of the first order- effects of axial diffusion", Chemical Engineering Journal, 23,193-199 (1982). [ Links ]

2. Chamkha, A.J. and I. Pop, "Effects of thermophoresis particle deposition in free convection boundary layer from a vertical flat plate embedded in a porous medium", Int. Communications Heat and Mass Transfer, 31, 421-430 (2004). [ Links ]

3. Cebeci, T and P. Bradshaw, Physical and Computational Aspects of Convective Heat Transfer, Springer-Verlag, New York, (1984). [ Links ]

4. Chamka, A., M. Jaradat and I. Pop, "Thermophoresis free convection from a vertical cylinder embedded in a porous medium", Int. J. Appl. Mech. Eng., 9, 471-481 (2004). [ Links ]

5. Cheng, W.T. and H.T. Lin, "Non-similarity solution and correlation of transient heat transfer in laminar boundary layer flow over a wedge", Int. J. of Eng. Sci., 40, 531-539 (2002). [ Links ]

6. Cheng, P and W.J. Minkowycz, "Free convection about a vertical flat embedded in a saturated porous medium with application to heat transfer from a dike", Journal of Geophysical Research, 82, 2040-2044 (1977). [ Links ]

7. Oran, E.S. and P.J. Boris, Numerical Simulation of Reactive flow, Cambridge University Press, U.K., Second Edition (2000). [ Links ]

8. Falkner, V.M and S.W. Skan, Philos. Mag., 12, 865-867 (1931). [ Links ]

9. Gill, S., Proceeding of Cambridge Society, London, United Kingdom, 96-123 (1951). [ Links ]

10. Goldsmith, P., and F.G. May, "Diffusiophoresis and thermophoresis in water vapour systems", in: C.N. Davies (Ed.), Aerosol Science, Academic Press, London, 163-194 (1966). [ Links ]

11. Goren, S.L., "Thermophoresis of aerosol particles in laminar boundary layer on flat plate", J. Colloid Interface Sci., 61, 77-85 (1977). [ Links ]

12. Hakiem, M.A.EL., A.A. Mohammadeian, S.M.M.EL. Kaheir and R.S.R. Gorla, "Joule heating effects on MHD free convection flow of a micro polar fluid", International Comms. Heat Mass Transfer, 26, 219-225 (1999). [ Links ]

13. Hales, J.M., L.C. Schwendiman and T.W. Horst, "Aerosol transport in a naturally-convected boundary layer", Int. J. Heat Mass Transfer, 15, 1837-1849, (1972). [ Links ]

14. Ingham, D and I. Pop, Transport Phenomena in Porous Media, I, Pergamon, Oxford (1998). [ Links ]

15. Ingham, D and I. Pop, Transport Phenomena in Porous Media, II, Pergamon, Oxford (2002). [ Links ]

16. Jayaraj, S., K.K. Dinesh and K.L. Pallai, "Thermophoresis in natural convection with variable properties", Heat Mass Transfer, 34, 469-475 (1999). [ Links ]

17. Kafoussias, N.G. and N.D. Nanousis, "MHD laminar boundary-layer flow over a wedge with suction or injection", Can. J. Phys., 75, 733-745 (1997). [ Links ]

18. Kafoussias, N.G., and A.G. Karabis, "An Effective Numerical Solution Scheme for Local Nonsimilarity Boundary Layer Analysis", In proceedings of the 2nd National Congress on Computational Mechanics, Chania, Greece, June 26-28, II, 801-809 (1996). [ Links ]

19. Kuo, B-L., "Heat transfer analysis for the Falkner-Skan wedge flow by the differential transformation method", Int. J. of Heat Mass Transfer, 48, 5036- 5042 (2005). [ Links ]

20. Minkowycz, W.J, E.M. Sparrow, G.E. Schneider and R.H. Pletcher, Handbook of numerical heat transfer, John Wiley and sons, New York (1988). [ Links ]

21. Nield, D.A. and A. Bejan, Convection in porous media, Second ed., Springer, New York (1999). [ Links ]

22. Selim, A., M.A. Hossain and D.A.S. Rees, "The effect of surface mass transfer on mixed convection flow past a heated vertical flat permeable plate with thermophoresis", Int. J. Thermal Sci., 42, 973-982, (2001). [ Links ]

23. Schlichting, H, Boundary Layer Theory, McGraw- Hill Inc, New York (1979). [ Links ]

24. Yih, K.A, Uniform suction/blowing effect on forced convection about a wedge: Uniform heat flux, Acta Mech., 128, 173-181 (1998). [ Links ]

25. Watanabe, T, "Thermal boundary layers over a wedge with uniform suction or injection in forced flow", Acta Mech., 83, 119-126 (1990). [ Links ]

Received: March 26, 2008.

Accepted: February 19, 2009.

Recommended by Subject Editor Orlando Alfano.