Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Latin American applied research

Print version ISSN 0327-0793

Lat. Am. appl. res. vol.41 no.3 Bahía Blanca July 2011

Use of hydrocolloids as edible covers to produce low fat french fries

A. Daraei Garmakhany†, N. Aghajani†and M. Kashiri‡

† Food Sciences and Technology, Agricultural Sciences & Natural Resources, University of Gorgan, Iran.

amirdaraey@yahoo.com; narjes_aghajani@yahoo.com

‡ Department of Food Science & Technology, Khazar University of Agricultural Sciences and Natural Resources, Mahmoud Abad, Iran. Kashiri_mahboobeh@yahoo.com

Abstract - The effect of different hydrocolloids as barrier agents on reduction of oil absorption in French fries during deep fat frying, investigated. Among different gums that used in this study, mixture of pectin and CMC 1% and xanthan gum 1.5% led to highest decrease in fat content and lowest decrease in amount of fat content observed in pectin 0.5% and guar gum 0.5% respectively. Strips that coated with xanthan gum, pectin and mixture of pectin and CMC had the highest amount of moisture content while the lowest moisture content were related to blank samples and strips that coated with guar gum and CMC. All coated strips in comparison with blank sample had lower amount of fat content significantly. Samples were coated with mixture of pectin and CMC 1% and blank sample need to maximum shearing force for cutting and coated samples with xanthan, guar and CMC gums need the lowest shearing force respectively.

Keywords - French Fries; Oil Absorption; Coating; Hydrocolloids.

I. INTRODUCTION

The potato is the world's root and tuber crop grown in the greatest quantities (FAO, 1999). Frying is one of the oldest cooking methods widely used to prepare tasty and crispy foods; which fried potato products being one of its largest applications. Deep-fat frying can be defined as the process of drying and cooking through contact with hot oil (Sahin et al., 1999; Lesinska and Leszczynski; 1989). In deep-fat fried products, both health and sensory aspects should be addressed to meet consumer demand. High heat transfer rates are largely responsible for the development of the desired sensorial properties in fried products (Hubbard and Farkas, 1999). Dehydration in hot oil at temperatures between 160 and 180ºC is characterized by very high drying rate that is critical for ensuring favorable structural and textural properties of the final product (Baumann and Escher, 1995).

In recent years, consumer's preference for low fat and fat-free products has been the driving force of this food industry to produce lower oil content fried potatoes that still retain the desirable texture and flavor. Pinthus et al. (1993) introduced the criterion UR, which expresses the ratio between the amount of oil uptake and water removed. Different means to reduce oil uptake in fried potatoes have been reported. For instance, vacuum frying may be an option for fried potatoes with low oil content and desired texture and flavor characteristics (Garayo and Moreira, 2002). Soaking of potato strips in NaCl solutions reduced oil uptake in French fries after frying (Bunger et al., 2003). Pre-drying of potatoes is as well a common way to reduce fat uptake in fried potatoes (Krokida et al., 2001; Moyano et al., 2002). Rubnov and Saguy (1997) added fructose to a restructured potato product that resulted in a change of the surface properties, with a reduction of absorbed oil after frying. The blanching step previous to frying in potato chip processing improves the color and texture, and could reduce in some cases the oil uptake by gelatinization of the surface starch (Califano and Calvelo, 1987).

Since most of the fat is taken up after removal of fried potatoes from the fat, the conditions in which the potato pieces are removed from the fryer are important for fat uptake (Aguilera and Hernández, 2000; Bouchon et al., 2003; Ufheil and Escher, 1996). Besides, properties of the surface of the potatoes are highly relevant for fat uptake, so the application of a coating is a promising route to reduce oil content (Mellema, 2003).

There are many options available to reduce fat uptake by application of coatings such as gellan gum, corn zein, cellulose derivatives (e.g. methylcellulose and hydroxyl propyl methyl cellulose), pectin, sodium alginate, etc. (García et al., 2002; Khalil, 1999; Rimac-Brncic et al., 2004; Williams and Mittal, 1999a; Altunakar, 2003). The aim of this study was to investigate the effect of coating with different hydrocolloids on oil uptake and quality attributes of potato French fries.

II. MATERIALS AND METHODS.

A. Preparation of Gums Suspensions

Carboxy methyl cellulose (CMC), pectin, guar and xanthan gums provided from Provisco Company of Iran. Aqueous suspensions of 0.5, 1% CMC, 0.5%, 1% pectin, 0.3, 0.5% and 1% guar gum and 0.5, 1 and 1.5% xanthan gum (w/v) provided and used for coating formulations.

Pectin was selected due to its ability to react with calcium content of potato tissue and formation of hard and dense structure that can decrease oil absorption. CMC was selected due to its gel formation ability in higher temperature that can form a thin film on the potato stripes during frying and so this film act as a barrier agent against oil absorption. By respect to the profitable properties of pectin and CMC gums and in order to study of the effect of the interaction between pectin and CMC gums on fat reduction of final potato stripes the mixture of these gums (at 0.5 and 1% concentration) was prepared for dipping process. Guar and xanthan gums were selected due to their good gelling properties.

The gum concentrations were chose according to economic aspect (all studied gums) and convenience to use as edible covers for dipping of strips in their suspensions (guar and xanthan gums).

All of the above concentrations weighed and slowly dispersed in boiled distilled water and homogenized by commercial blender, the ratio of suspensions volume to potato slices was (3/1 "w/v") and the solution was kept under constant stirring until it attained ambient temperature (30-33°C).

B. Sample Preparation

Potato variety Kenebk purchased from Seed and Plant breeding Institute of Jahad Agricultural Organization, Golestan province of Iran and immediately its physicochemical properties (Table 1) were analyzed (AOAC, 2005). Potato tubers were moved to a cold store at 5-70C with relative humidity of 80%. Before frying, potatoes were removed from cold store and kept at ambient temperature (30-33°C) for two weeks in order to decrease the amount of reducing sugars which have been increased during cold storage, then after peeling with an abrasive peeler (Esfahan machine); they were converted to pieces of 6x1x1 cm by means of a domestic striper. The blanching was performed in boiling water (90-95°C) for 4 min and then the products washed immediately with cool water. After blanching, samples of potato stripes weighted and dipped in the coating suspensions for 1 minute and rinsed until excessive gum drained then weighted and immediately fried.

Table 1- Some of physicochemical properties of raw potato tubers

Coated and uncoated (control) samples, fried in a controlled temperature domestic deep-fat fryer (Teafall) filled with 2.5 L of commercial frying oil which purchased from local market. Frying conditions were 2.5 minute at 175°C. These frying conditions selected in a previous work by sensory analysis of products fried at different times and temperatures (Daraei Garmakhany et al., 2008).

C. Experiment

Dry matter and moisture content of the raw potatoes and French fries analyzed based on AOAC (2005). Analysis of reducing sugars and sucrose, performed by the Lin Aynon (Fehling) method as described by AOAC (2005).

D. Water Content

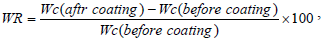

Water content (WC) was determined by weight loss of fried products, upon drying in an oven at 105°C until a constant weight was reached. Relative increase of water retention% (WR) in the coated product relative to the uncoated one was calculated as follows:

| (1) |

where WC-coated and WC-uncoated are the water contents of the coated and uncoated samples, respectively. For each coating formulation, results were obtained using all samples from at least three different batches.

E. Lipid Content

Lipid content (LC) of fried products was determined on dried samples using continuous Soxhlet extractions. For extraction of lipid, petroleum ether (Merck Company) was used. Oil uptake decrease % (OU) in the coated product relative to the uncoated one was calculated as follows:

| (2) |

where LC-coated and LC-uncoated are the lipid contents of the coated and uncoated samples respectively. For each coating formulation, results were obtained using all samples from at least three different batches.

Fat and water contents were measured after frying the coated samples. The purpose of these measurements was to observe the changes in product composition due to coating, if any.

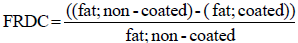

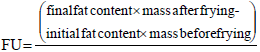

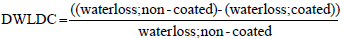

| (3) |

| (4) |

| (5) |

| (6) |

| (7) |

where FRDC is fat reduction due to coating, WIDC is water increase due to coating, WLDF is water loss during frying, FU is fat uptake and DWLDC is decrease in water loss due to coating.

F. Coating pick-up calculations

Coating pick-up was calculated from the difference between coated weight and non-coated weight of raw potato sample. It can be formulated as in Eq. (8) (Parinyasiri et al., 1991);

% Coating Pick-Up = (C - I)/ I ×100, (8)

where C is the weight of raw coated potato strips (g) and I is the initial weight of raw non-coated potato strips (g).

G. Frying yield calculations

Percentage of frying yield was obtained by considering the weight of the fried potato strips and the raw potato strips after coating. It can be formulated as Eq. (9) (Parinyasiri et al., 1991);

% Frying Yield = (CW/C)×100, (9)

where CW is the cooked weight of coated potato strips (g) and C is the weight of non-cooked coated potato strips (g).

H. Colorimetric measurements

The color parameters (Hunter L, a, b) were measured with a Data color, color reader (Text Flash, USA). The three color coordinates ranged from L=0 (black) to L=100 (white), -a (greenness) to +a (redness), and -b (blueness) to +b (yellowness). Total color difference (ΔE) was calculated from Eq. (10) (Ling et al., 1998);

ΔE = [(L- L standard) 2 + (a-a standard) 2 + (b-b standard) 2]1/2, (10)

where standard values referred to the BaCl2 plate (L=96.9, a=0 and b=7.2) is used for calibrating the colorimeter.

Triplicate readings were carried out at room temperature on three different locations of each slice: the center point and both ends, and the mean values were recorded.

I. Texture measurement

Texture of coated and uncoated potato strips were measured by use of Instron machine (1140, Instron company of England).

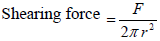

Shear and cutting forces were measured based on Warner-Bratzler Shear methods. Shearing force was formulized as below Eq:

| (11) |

Triplicate readings were carried out at room temperature on three different locations of each slice: the center point and both ends, and the mean values were recorded (Akdeniz, 2004).

J. Statistical analysis

This study was conducted on completely randomized design. All these experiments were replicated three times and the average values were reported. The effect of different concentration of gums on different quality factors of produced french fries were determined using the analysis of variance (ANOVA) method and significant differences of means were compared using the Duncan's test at 5% significant level using SAS software.

K. Result and discussion

Physicochemical properties of potato tubers were shown in Table 1. As it can be seen the kenebk variety had high amount of dry mater content and good specific gravity (1.09), so we can expect that French fries which produce by this variety had lower oil uptake during frying. Result showed that this potato variety had low reducing sugar content (0.62 mg/100 g sample) and so it is suitable variety to produce fired products that need to have a yellow color.

As it can be seen from table 2 xanthan gum 1.5 and 1% with amount of 21.6% had the highest coating pick up (P<0.05). The lowest coating pick up was related to pectin gum that can be because of its gel formation ability. In general, by increase of gums concentration, the coating pick up percentage is increasing (Table 2) which is not uniform and straight forward. The higher amount of coating pick up in xanthan gum may be due to ability of thick gel formation.

Table 2 - Effect of coating with hydrocolloids on some of quality attribute of potato French fries

Xanthan gum 1.5% and pectin gum 1%, led to maximum water loss prevention during frying and coating with these gums led to the highest decrease of water loss in fried strips. Guar gum 1% had the lowest decrease of water loss between other gums. Decrease of water loss in potato strips coated with pectin may be result of interaction between pectin and structural parts of strips which lead to hard texture with minimum water loss.

Hydrocolloids due to their barrier properties form a protective layer on the surfaces of stripes and decrease water loss during frying, same result reported by Khalil (1999), Williams and Mittal (1999b), Balasubramaniam et al. (1997). Among different gums were used in this study, xanthan gum 1% and guar gum 1% led to highest and lowest water retention in fried products (P<0.05). Different gums led to different water increase in fried strips but this differences were not significant (P>0.05). Increase in water content due to coating, may be result of barrier properties of coating agents which prevent water loss during frying and by this mechanism water content of coated strips were higher than non coated strips. Water content of coated stripes was higher than non coated strips. Different gums due to different barrier properties and different gel formation ability led to different water retention in fried product. Indeed these properties related to gums structure and its functional groups.

Different gums led to different decrease in amount of oil absorption in final products. Among different gums that used in this study, mixture of pectin and CMC 1% and xanthan gum 1.5% led to highest decrease in fat content and the lowest decrease in amount of fat absorption observed in pectin gum 0.5% and guar gum 0.5% respectively. Coating with xanthan gum in all concentrations showed the high decrease in fat content. Coating with mixture of pectin and CMC in both concentrations also led to higher decrease in fat content of fried strips, this can be due to synergistic effect of tow gums on each others. Mixture of pectin gum and CMC in both concentrations decreased fat content more than each of them that used alone. Our Result showed that, by increase of gums concentration fat content, decreased.

According to Table 3 by decrease in water loss due to water retention properties of hydrocolloids, coated strips had higher moisture content in comparison with non coated strips. Coating with xanthan, pectin and mixture of pectin and CMC gums, led to the highest amount of moisture content while the lowest moisture content were related to blank sample and coated strips with guar and CMC gums respectively (P<0.05). Among different concentration of xanthan gum that used in this study, xanthan gum 1% led to the highest amount of moisture content in final product and xanthan gum 0.5% had the lowest moisture content (P>0.05). In mixture gum decrease in water loss may be due to synergistic effect of interaction between pectin with calcium content of potato strips and thermo gelling properties of CMC gum that led to higher moisture content in final products. Among studied coating agents, by respect to fat content, mixture of pectin gum and CMC were better than other gums. The lowest fat content observed in strips that coated with mixture of pectin and CMC 1% and xanthan gum 1.5 % and the highest fat content were related to coated samples with pectin 0.5%, guar gum 0.5% and CMC 0.5% respectively. All coated strips in compared with blank sample had the lower amount of fat content, and coating with hydrocolloids significantly reduced fat content (P<0.05). During frying water content of potato strips changed to vapor and this vapor create a suction presser in fried strips. Hence the potato strips removed from the fryer this suction pressure led to penetration of oil instead evaporated water. According to this fact every factor that prevents water loss during frying led to decrease in oil uptake. Frying efficiency represent weight loss of potato strips during frying. Frying processes led to water loss of fried strips, and so decrease of frying efficiency.

Table 3-Effect of coating with hydrocolloids on fat and moistures content of potato French fries

Hydrocolloids due to their barrier properties and water retention ability prevent water loss; and so led to increase in frying efficiency value (p>0.05).

As it can be seen from Table 4 samples were coated with mixture of pectin and CMC gums 1% and blank sample need to maximum shearing force for cutting and the lowest shearing force observed in samples were coated with xanthan, guar and CMC gums respectively. According to results of Rovedo et al. (1999), Olewnick and Kulp (1993), final texture of fried products affected by food composition, therefore interactions between proteins, starch and their fractions (amylose and amylopectin) were most important for final products quality and texture. By this respect we can say that, mixture of pectin and CMC and pectin gums due to interaction with structural compound of potato, led to hard texture and increase of shearing force in final products (P<0.05). In blank samples increase of shearing force can be related to increase of moisture loss during frying which produce a hard crust on potato strips surface.

Table 4 - Effect of coating with hydrocolloids on color and texture of potato French fries

As can be seen from Table 4 the highest amount of L value was related to CMC 0.5%, guar gum 0.5%, mixture of pectin and CMC 0.5% and the lowest amount of L value observed in sample were coated with pectin 0.5%. As can be seen the highest amount of a value were related to CMC 1%, pectin 0.5% and mixture gum 1% and coating with these gums led to maximum redness. The lowest amount of a value was observed in blank samples and samples were coated with different concentration of xanthan gum (Table 4). As can be seen coating of potato strips led to increase b value and the highest and lowest amount of b value observed in strips that coated with CMC 1% and blank samples respectively. Coated and no coated samples had no significant difference in L, a, b value (P>0.05). Coated and no coated samples had no significant difference in term of Δ;E (P>0.05). As can be seen the highest amount of ΔE was observed in samples coated with CMC 0.5%, guar 0.5% and mixture gum 0.5% and the lowest ΔE was related to samples were coated with different concentration of pectin gum and xanthan 1.5% (Table 4). There were not any previous study that shows how different gums and its concentration led to different value of a, b, c and ΔE in the literature.

III. CONCLUSION

Result of this study showed that coating with hydrocolloids due to their barrier properties led to increase of water retention and decrease of oil absorption in comparison with blank samples with out any significant differences in color and appearance. Coated strips had no very hard texture and by final frying, their texture will not be very hard in compared with blank sample. Among different studied gums CMC 1%, mixture of pectin and CMC in both concentrations and xanthan gum in all concentrations (0.5, 1 and 1.5%) led to the lowest fat absorption. Among these gums CMC 1% and both concentration of mixture of pectin and CMC and pectin 1% due to their facility to use, suggested for coating and usage in industrial French fries production.

ACKNOWLEDGMENT

Authors would like to acknowledge Gorgan University of Agricultural Sciences and Natural Resources to provide equipment and support for this project.

REFERENCES

1. Aguilera, J.M. and H.G. Hernández, "Oil absorption during frying of frozen par fried potatoes," J. Food Sci.,65, 476-479 (2000). [ Links ]

2. Akdeniz, N, Effects of different batter formulations on quality of deep-fat fried carrot slices, Graduate Thesis , Natural and Applied Sciences of Middle east Technical University (2004). [ Links ]

3. Altunakar, B, Functionality of different batters in deep-fat fried chicken nuggets, MS. Thesis, The department of Food Engineering, METU (2003). [ Links ]

4. AOAC, Official Methods of the Association of Official Analytical Chemists, Arlington (2005). [ Links ]

5. Balasubramaniam, V.M., M.S. Chinnan, P. Mallikarjunan and R.D. Phillips, "The Effect of edible film on oil uptake and moisture retention of a deep-fat fried poultry product," J. Food Process Eng, 20, 17-29 (1997). [ Links ]

6. Baumann, B. and E. Escher, "Mass and heat transfer during deep fat frying of potato slices. Rate of drying and oil uptake," J. LWT., 28, 395-403 (1995). [ Links ]

7. Bouchon, P., J.M. Aguilera and D.L. Pyle, "Structure oil absorption relationships during deep-fat frying," J. Food Sci, 68, 2711-2716 (2003). [ Links ]

8. Bunger, A., P. Moyano and V. Rioseco, "NaCl soaking treatment for improving the quality of French-fried potatoes," Food Research Int, 36, 161-166 (2003). [ Links ]

9. Califano, A.N. and A. Calvelo, "Adjustment of surface concentration of reducing sugars before frying of potato strips," J. Food Proc and Preser, 12, 1-9 (1987). [ Links ]

10. Daraei Garmakhany, A., H.O. Mirzaei, M. Kashani Nejad, M and Y. Maghsudlo, "Study of oil uptake and some quality attributes of potato chips affected by hydrocolloids," Eur. J. Lipid Sci. Technol, 110, 1045-1049 (2008). [ Links ]

11. FAO, Production year book 1998, Food and Agriculture Organization of the United Nations., Rome, 52, 80-90 (1999). [ Links ]

12. Garayo, J., and R. Moreira, "Vacuum frying of potato chips," J. Food Eng., 55, 181-191 (2002). [ Links ]

13. García, M.A., C. Ferrero, N. Bértola, M. Martino and N. Zaritzky, "Edible coatings from cellulose derivatives to reduce oil uptake in fried products," Innovative Food Sci and Emer Tech, 3, 391-397 (2002). [ Links ]

14. Hubbard, L.J. and B.E. Farkas, "A. method for determining the convective heat transfer coefficient during immersion frying," J. Food Process Eng, 22, 201-214 (1999). [ Links ]

15. Khalil, A.H, "Quality of French fried potatoes as influenced by coating with hydrocolloids," Food Chem, 66, 201-208 (1999). [ Links ]

16. Krokida, M.K., V. Oreopolou, Z.B. Maroulis and D. Marinos-Kouris, "Deep fat frying of potato strips -quality issues," J. drying Tech., 19, 879-935 (2001). [ Links ]

17. Lesinska, G. and W. Leszczynski, "Potato science and technology," Elsevier Science, NY. USA (1989). [ Links ]

18. Ling, D., A. Gennadios, M.A. Hanna and S.L. Cuppett, "Quality evaluation of deep-fat fried onion rings," J. Food Qual., 21, 95-105 (1998). [ Links ]

19. Mellema, M, "Mechanism and reduction of fat uptake in deep fat fried foods," Trends in Food Sci and Tech., 14, 364-373 (2003). [ Links ]

19. Moyano, P.C., V.K. Ríoseco and P.A. Gonzaléz, "Kinetics of crust color changes during deep-fat frying of impregnated French fries," J. Food Eng., 54, 249-255 (2002). [ Links ]

20. Olewnick, M. and K. Kulp, "Factors influencing wheat flour performance in batter systems," Cereal Foods World., 38, 679-685 (1993). [ Links ]

21. Parinyasiri, T., T.C. Chen and R.J. Reed, "Yields and breading dispersion of chicken nuggets during deep-fat frying as affected by protein content of breading flour," J. Food Proce and Preserv., 15, 369-376 (1991). [ Links ]

22. Pinthus, E.J., P. Weinberg and I.S. Saguy, "Criterion for oil uptake during deep-fat frying," J. Food Sci., 58, 204-205 (1993). [ Links ]

23. Rimac-Brncic, S., V. Lelas, D. Rade and B. Simundic, "Decreasing of oil absorption in potato strips during deep fat frying," J. Food Eng., 64, 237-241 (2004). [ Links ]

24. Rovedo, C.O., M.M. Pedreno-Navarro and R.P. Singh, "Mechanical properties of a corn starch product during the post-frying period," J. Texture Stud., 30, 279-290 (1999). [ Links ]

25. Rubnov, M. and I.S. Saguy, "Fractal analysis and crust water diffusivity of a restructured potato product during deep-fat frying," J. Food Sci., 62, 135-137, 154 (1997). [ Links ]

26. Sahin, S., S.K. Sastry and L. Bayindirili, "Heat transfer during frying of potato slices," J. LWT., 32, 19-24 (1999). [ Links ]

27. Ufheil, G. and F. Escher, "Dynamics of oil uptake during deep fat frying of potato slices," J. LWT., 29, 640-644 (1996). [ Links ]

28. Williams, R. and G.S. Mittal, "Low-fat fried foods with edible coatings: modeling and simulation," J. Food Sci., 64, 317-322 (1999a). [ Links ]

29. Williams, R. and G.S. Mittal, "Water and fat transfer properties of polysaccharide films on fried pastry mix," J. LWT., 32, 440-445 (1999b). [ Links ]

Received: April 18, 2010

Accepted: September 8, 2010

Recommended by Subject Editor: Ricardo Gómez