Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Latin American applied research

versión impresa ISSN 0327-0793

Lat. Am. appl. res. vol.41 no.3 Bahía Blanca jul. 2011

Effect of water temperature, variety and shelf life on rehydration kinetics of microwave dried potato cubes

A. Salimi Hizaji, Y. Maghsoudlou and S.M. Jafari

Food Eng. Department, Natural Resources and Agricultural Sciences University, Gorgan, Iran.

azadeh9025@yahoo.com, ymaghsoudlou@yahoo.com, smjafari@gau.ac.ir

Abstract - In this work we compared the kinetic of the rehydration process of potatoes cubes and effects of water temperature, shelf life and variety on it. Rehydration ratio, water absorption capacity and moisture content were examined during soaking. Samples were dried in a microwave oven (300W), and subsequently rehydrated in a water bath at two temperatures (23±2ºC and 100±2Cº). Peleg's model was successfully applied to experimental data and the corresponding parameters were obtained and correlated with temperature. The parameters of the model considered were found to be greatly affected by the water temperature during rehydration. In particular the temperature increment increases the rate of rehydration and the equilibrium moisture content of the rehydrated products but shelf life decreased all the parameters.

Keywords - Kinetic; Rehydration; Peleg Model; Potatoes; Water Temperature; Shelf Life.

I. INTRODUCTION

A growing resistance of consumers to the use of chemical additives in the preservation of foods, combined with the rapid expansion of the fast-food industry, shows the potential for the use of dehydrated potato products, with no chemical additives, as a rehydrated product or as a component of vegetable mixtures and soups (Maskan, 2001).

Potato is one of the most important agricultural crops and there is remarkable loss of it because of unfavorable storage conditions. Therefore, it is vital to convert raw potatoes into some processed products such as dried ones.

Dehydration of food products, leading to a prolongation in their shelf life, a greater diversity and an important volume decrease, could be expanded further with improvements in product quality and process applications (Maskan, 2001). The selection of proper drying conditions is important for decreasing thermal stress and maintaining the quality of key compounds in the rehydrated product.

Various mathematical models describing the drying mechanism have been suggested for the optimization of the process and the design of an efficient drier. Such disadvantages, compounded by long drying times and low energy efficiency, have promoted research into alternative drying methods.

Microwave drying is a relatively cheap method, in which dipole heating causes water to move towards the product surface. Industrial applications of microwave energy include dehydration (Nijhuis et al., 1996). Microwave drying has several advantages over conventional hot air drying, such as higher drying rate, minimal heating at locations with less water, thus reducing overheating the atmosphere, and at locations where heating is not required (Kiranoudis and Tsami, 1997; Sharma and Prasad, 2004). In microwave heating, as the temperature inside the material approaches the boiling point of water, pressure development becomes significant. This increase in vapor pressure facilitates and transfer of water to the outside(Kaensup and Wongwises, 2004; Zhang and Tang, 2006), and generates higher drying rates than conventional drying, where heat is transferred from the surface to the inside of the solids (Maskan, 2001; Khraisheh and McMinn, 2004; Sharma and Prasad, 2004). On the other hand, experimental work has shown that the use of microwaves in drying improves color and rehydration capacity, and reduces product shrinkage (Maskan, 2001).

Most of the dehydrated products are usually rehydrated during their use. Mathematical models of dehydration and rehydration operations are important in the design and optimization of those operations (Vagenas and Marinos-Kouris, 1991). It chiefly involves determination of drying and rehydration kinetics, which describe the mechanisms and the influence that certain process variables exert upon moisture transfer (Sereno and Medeiros, 1990). In typical industrial applications, kinetic models are often empirical equations involving parameters which are functions of the main process variables.

Rehydration can be considered as a measure of the injury to the material caused by drying and treatment proceeding dehydration (McMinn and Magee, 1997a). Rehydration of dried plant tissues is composed of three simultaneous processes: the imbibitions of water into dried material, the swelling and the leaching of soluble (Lewicki, 1998; McMinn and Magee, 1997b).

The objectives of the present work were to study the effect of water temperature (23±2º and 100±2º), shelf life and variety (three cultivated potatoes of Golestan province of Iran so-called Agria, Satina and Kenebek) which impress the quality of dehydrated potato cubes and their ability of water absorption in order to estimate best variety, water temperature and time of consumption.

Nomenclature:

X moisture content (kg/kg db)

Xi initial moisture content (kg/kg db)

Xf moisture content of fresh sample(kg/kg db)

Xeq equilibrium moisture content(kg/kg db)

M weight of sample(kg)

Mi initial weight of dried sample(kg)

Mf weight of fresh sample(kg)

RR rehydration ratio

K1 parameter of Peleg's model Eq. (s kg d.b./kgwater)

K2 parameter of Peleg's model Eq. (kg d.b./kgwater)

T time of rehydration(min)

WAC water absorption capacity

II. REHYDRATION KINETICS MODELING

Although several mechanisms have been proposed to describe rehydration process based on different mass transports such as diffusion and capillary flow, it is not clear which is the predominant mechanism (Saguy et al., 2005). Among the various models, empirical models are the most widely employed because of mathematical simplicity and utility. Peleg (1988) proposed an empirical model to describe the water absorption kinetics during rehydration, which is given by:

X = Xi + T / (K1+K2T), (1)

where K1 is a kinetic parameter and K2 is another parameter related to equilibrium moisture content, Xeq. When t→∞, equilibrium moisture content can be calculated by:

Xeq = Xi + 1/ K2. (2)

Equation 1 can be linearized:

T /(X- Xi) = K1+K2T . (3)

Allowing for the determination of K1 and K2 values by linear regression of experimental data. This model has been successfully applied to different products such as chestnut (Moreira et al., 2008), apple (Bilbao-Sáinz et al., 2005), carrot (Cunningham et al., 2007), mushroom (García-Pascual et al., 2005) and rice (Yadav and Jindal, 2007).

The water absorption capacity (WAC) index estimates the ability of the matrix to absorb water with respect to the water loss during drying, and usually varies in the range 0 ≤ WAC ≤ 1, and is defined by:

WAC = (M X - Mi Xi) / (Mf Xf - Mi Xi). (4)

The rehydration ability of the dehydrated products is usually expressed by the rehydration ratio (RR), defined as follows:

RR = (X+1) / (Xi +1) . (5)

III. MATERIALS AND METHODS

A. Materials.

Three potato cultivars (Agria, Satina and Kenebek) were purchased in a local market of Gorgan city of Iran. Initial moisture content was 82.05, 82.28 and 81.405 percent respectively. Potatoes were peeled and cut to 1×1×1 cm cubes. After that, to inhibit browning, samples were blanched in hot water (97±2ºC) for three minutes.

B. Drying treatments.

To dry samples, a microwave oven was used (Samsung CE3110N) and samples were dried in 300W power to reach to 6% moisture content (wet basis). Then dried samples were cooled and packed in polyethylene bags and stored in room temperature (25±2ºC). Vacuum of packages was 30%, their thickness was 1mm and there was not any permeability of water and moisture.

C. Rehydration.

The dried potato samples were then rehydrated by immersion in distilled water at a thermostatically controlled temperature (Cunningham et al., 2007). At specified timeintervals, the potato samples were removed from the liquid, blotted with tissue paper to remove superficial water, and weighed. Soaking times up to reach constant weight of samples were examined with time intervals ranging from 10 min at the beginning of the rehydration process to 30 min towards the end of water absorption for water degree 23±2ºC and 10sec for water degree 100±2Cº (Cunningham et al., 2007). No correction was made for lost solids, as the quantity of water absorbed was much greater than the quantity of solids leached (Maskan, 2001). Each rehydration experiment was performed in triplicate.

IV. RESULTS AND DISCUSSIONS:

A. Rehydration kinetics

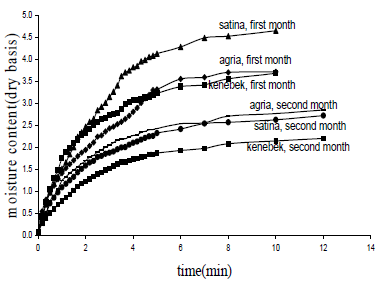

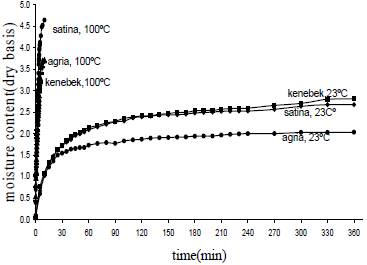

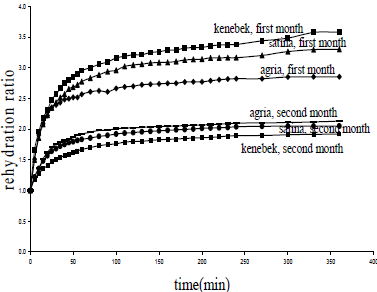

Figures 1 and 2 show effect of variety and shelf life on experimental moisture contents of potatoes in two water temperature (23±2ºC and 100±2ºC). Rehydration kinetics shows an initial steep increase in water absorption followed by a decrease in rehydration rate. This asymptotic behavior is related to the decrease of driving force for water transfer as rehydration progresses and the system is close to equilibrium. In tepid water (23±2ºC), between three cultivars, Kenebek had the highest moisture content in the first month of experiment but in second month, it showed a significant decrease in final moisture content.

Figure1. Effect of variety and shelf life on moisture content of samples in 23ºC

Figure 2. Effect of variety and shelf life on moisture content of samples in 100ºC

In hot water, Satina variety had the highest moisture content in the first month. From these results, it can be concluded that structure of Kenebek variety had more sensibility to temperature and changes in its product induced by temperature causing a decrease of permeability within the potato structure and perhaps a loss of solids during rehydration. Abu-Ghannam and McKenna (1997), Maharaj and Sankat (2000) and García-Pascual et al. (2005). In the other hand, in Figs. 1 and 2, it is shown that shelf life had a significant effect on moisture content of samples and all three cultivars, had lower capability for absorbing water after storage. This can be explained by structure degradation of potatoes because of changes which happen in starch during storage that lead to less capability for absorbing and holding water. Similar results have reported by Monteils et al. (2002).

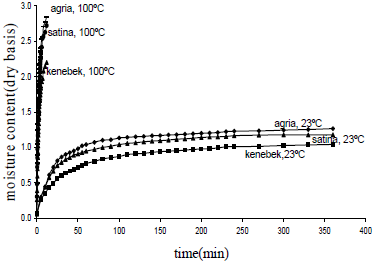

As it has been shown in Fig. 3 and 4, Rehydration temperature showed a marked effect on rehydration rates and on amounts of absorbed water. Higher temperatures result in an increase in both the magnitudes. Similar behavior was observed by other authors who experimented different food materials such as green pea, banana, carrot, pumpkin, onion, mushroom, corn, potato, leek, garlic, tomato, pepper, and amaranth grains (Krokida and Marinos-Kouris, 2003; Krokida and Philippopoulos, 2005; Planinic et al., 2005; Resio et al., 2006).

Figure 3. Effect of water temperature on moisture content of samples in first month

Figure 4. Effect of water temperature on moisture content of samples in second month

At the highest temperature tested, a considerable increase was observed in the rehydration rate, which can be due to the irreversible changes that take place in the starch granules as a result of gelatinization process, which is corroborated by the turbidity observed in the liquid after rehydration. Similar behavior was also observed during rehydration of rice (Bello et al., 2007). In order to evaluate the water transfer during rehydration process, it is necessary to take into account the leaching flows. Normally, these flows are neglected or considered constant during process.

B. Peleg's modeling

Table 1 shows values of K1 and K2 parameters and equilibrium moisture content obtained from Eq. (3) at each temperature and initial moisture content tested, respectively.

Table 1. Parameters and coefficients of determination of Eq. (1) and values equilibrium moisture content, Eq. (2), for rehydration at two temperatures

Values of K1 decrease with temperature at each initial moisture content. In this way, water transfer is promoted by increase in temperature. Similar behavior was found by other authors with regard to the rehydration of other products (Moreira et al., 2008, García-Pascual et al., 2005; Maskan, 2002; Turhan et al., 2002). K2 values also decrease with temperature, indicating that water absorption capacity increases with temperature. This capacity depends on the type of material, structure of tissue, and chemical composition. Other authors indicate that K2 value can change if structure or other properties are modified by temperature during rehydration (García- Pascual et al., 2005). In this manner, K2 parameter increases with temperature during rehydration of chestnuts (Moreira et al., 2008), chickpea (Turhan et al., 2002), and carrot (Planinic et al., 2005). Consequently, equilibrium moisture content of potato increases with temperature (Table 1).

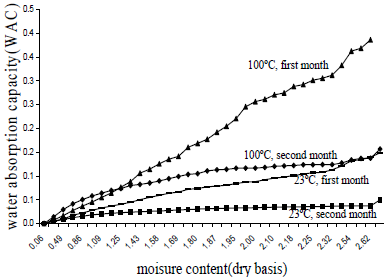

C. Water absorption capacity (WAC)

Rehydration process depends on structural changes in vegetal tissues and cells of food material during drying, which produces shrinkage and collapse and reduces the water absorption capacity, thereby preventing the complete rehydration of the dried product (Krokida et al., 2003). WAC index is a function of temperature, rehydration times, and moisture content of samples.

Figures 5, 6 and 7show the behavior of WAC with temperature, shelf life and moisture content. As it is shown, at higher temperatures, WAC varies more rapidly, but practically changes linearly with moisture content. WAC values of dried samples were higher at 100ºC in compare to 23ºC. In fact, WAC values increase with temperature because of toeless of soluble compounds under these conditions. Similar results were found during rehydration of strawberry (Moreira et al., 2008, Meda and Ratti, 2005).

Figure 5. Effect of water temperature and shelf life on water absorption capacity of Agria samples

Figure 6. Effect of water temperature and shelf life on water absorption capacity of Kenebek samples

Figure 7. Effect of water temperature and shelf life on water absorption capacity of Satina samples

C. Rehydration Ratio (RR)

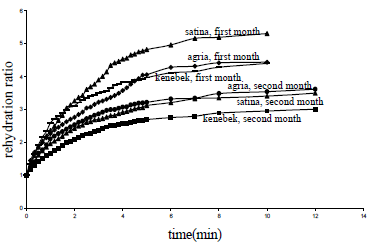

The RR for all the examined materials for a both rehydration temperatures (23ºC and 100ºC) is presented in Figs. 8 and 9.

Figure 8. Effect of variety and shelf life on rehydration ratio of samples in 23ºC

Figure 9. Effect of variety and shelf life on rehydration ratio of samples in 100ºC

The rehydration ratio ranges between 1 and 6 for all examined samples, having the higher values for Kenebek in 23ºC and Satina in 100ºC. Lower RR values are caused by structural damages taking place during dehydration (Krokida and Marinos-Kouris, 2003).

V. CONCLUSIONS

The water temperature was found to influence the rehydration rates and the equilibrium moisture Content in a positive way. At 100 ºC, rehydration rate dramatically increases mainly by gelatinization of starch. The rehydration ratio ranges between 1 and 6 for all examined materials. The rehydration ability appeared to show a hysteresis after two months storage, due to cellular and structural disruption that takes place in the starch. Peleg's model was successfully applied to describe the rehydration kinetics of potato. Parameters of this model were satisfactorily correlated with temperature through exponential (K1) and linear (K2) regressions. With regard to rehydration index, WAC increase with time and temperature, showed a linear variation with moisture content. Between varieties, Kenebek had the highest water absorption in 23Cº but in hot water, it showed a significant decrease in final moisture content and Satina took its place. It can be concluded that structure of Kenebek had more sensibility to temperature and changes in its product induced by temperature causing a decrease of permeability within the potato structure and perhaps a loss of solids during rehydration. Also, shelf life had a significant effect on moisture content of samples and all three cultivars, had lower capability for absorbing water after storage. This can be explained by structure degradation of potatoes because of changes which happen in starch during storage that lead to less capability for absorbing and holding water. So best time for consumption of products was before two months.

REFERENCES

1. Abu-Ghannam, N. and B. McKenna, "Hydration kinetics of red kidney beans (Phaseolus vulgaris L.)," J. Food Sci, 62, 520-523 (1997). [ Links ]

2. Bello, M.O., M.P. Tolaba and C. Suarez, "Water absorption and starch gelatinization in whole rice grain during soaking," J. Food Sci. and Tech., 40, 313-318 (2007). [ Links ]

3. Bilbao-Sáinz, C., A. Andres and P. Fito, "Hydration kinetics of dried apples as affected by drying conditions," J. Food Eng., 68, 369-376 (2005). [ Links ]

4. Cunningham, S.E., W.A.M. McMinn, T.R.A. Magee and P.S. Richardson, "Modeling water absorption of pasta during soaking," J. Food Eng., 82, 600-607 (2007). [ Links ]

5. Cunningham, S.E., W.A.M. McMinn, T.R.A. Magee and P.S. Richardson, "Effect of processing conditions on the water absorption and texture kinetics of potato," J. Food Eng., 84, 214-223 (2007). [ Links ]

6. García-Pascual, P., N. Sanjuan, J. Bon, J.E. Carreres and A. Mulet, "Rehydration process of Boletus edulis mushroom: characteristics and modeling," J. Science of Food and Agriculture, 85, 1397-1404. (2005). [ Links ]

7. Kaensup, W. and S. Wongwises, "Combined microwave/fluidized bed drying of fresh peppercorns," J. Drying Tech., 22, 779-794 (2004). [ Links ]

8. Khraisheh, M.A.M. and W.A.M. McMinn, "Quality and structural changes in starchy foods during microwave and convective drying," J. Food Research International, 37, 497-503 (2004). [ Links ]

9. Kiranoudis, C.T. and E. Tsami, "Microwave vacuum drying kinetics of some fruits," J. Drying Tech., 15, 2421-2440 (1997). [ Links ]

10. Krokida, M.K. and D. Marinos-Kouris, "Rehydration kinetics of dehydrated products," J. Food Eng., 57, 1-7 (2003). [ Links ]

11. Krokida, M.K., V.T. Karathanos, Z.B. Maroulis and D. Marinos-Kouris, "Drying kinetics of some vegetables," J. Food Eng., 59, 391-403 (2003). [ Links ]

12. Krokida, M.K. and C. Philippopoulos, "Rehydration of dehydrated foods," J. Drying Tech., 23, 799-830. (2005). [ Links ]

13. Lewicki, P.P., "Effect of pre-drying treatment, drying and rehydration on plant tissue properties: a review," International J. Food Properties, 1, 1-22. (1998). [ Links ]

14. Maharaj, V. and C.K. Sankat, "The rehydration characteristics and quality of dehydrated dasheen leaves," J. Canadian Agricultural Eng., 42, 81-85 (2000). [ Links ]

15. Maskan, M., "Drying shrinkage and rehydration characteristics of kiwifruits during microwave drying," J. Food Eng., 48, 177-182 (2001). [ Links ]

16. Maskan, M., "Effect of processing on hydration kinetics of three wheat products of the same variety," J. Food Eng., 52, 337-341 (2002). [ Links ]

17. McMinn, W.A.M. and T.R.A. Magee, "Physical characteristics of dehydrated potatoes-Part II," J. Food Eng., 33, 49-55 (1997a). [ Links ]

18. McMinn, W.A.M. and T.R.A. Magee, "Quality and physical structure of dehydrated starch based system," J. Drying Tech., 15, 49-55 (1997b). [ Links ]

19. Meda, L. and C. Ratti, "Rehydration of freeze-dried strawberries at varying temperatures," J. Food Processing and Eng., 28, 233-246 (2005). [ Links ]

20. Monteils, V., S. Jurjanz, O. Colin-Sachoellen, G. Blanchart and F. Laurent, "Kinetics of ruminal degradation of wheat and potato starches in total mixed rations," J. American Society of Animal Sci., 80, 235-241 (2002). [ Links ]

21. Moreira, R., F. Chenlo, L. Chaguri and C. Fernandes, "Water absorption, texture and color kinetics of air- dried chestnuts during rehydration," J. Food Eng., 86, 584-594 (2008). [ Links ]

22. Nijhuis, H.H., E.M. Torringa and H. Luyten, "Research need and opportunities in the dry conservation of fruits and vegetables," J. Drying Tech., 14, 1429-1458 (1996). [ Links ]

23. Peleg, M.A., "empirical model for the description of moisture sorption curves," J. Food Sci., 53, 1216-1219 (1988). [ Links ]

24. Planinic, D., S.T. Velic, M. Bilic and A. Bucic, "Modelling of drying and rehydration of carrots using Peleg's model," J. European Food Research and Tech., 221, 446-451 (2005). [ Links ]

25. Resio, A.C., R.J. Aguerre and C. Suarez, "Hydration kinetics of amaranth grain," J. Food Eng., 72, 247-253 (2006). [ Links ]

26. Saguy, I.S., A. Marabi and R. Wallach, "New approach to model rehydration of dry food particulates utilizing principles of liquid transport in porous media," Trends in Food Sci & Tech., 16, 495-506 (2005). [ Links ]

27. Sereno, A.M. and G.L. Medeiros, "A simplified model for the prediction of drying rates for foods," J. food Eng., 12, 1-11 (1990). [ Links ]

28. Sharma, G. and S. Prasad, "Effective moisture diffusivity of garlic cloves undergoing microwave-convective drying," J. Food Eng., 65, 609-617 (2004). [ Links ]

29. Turhan, M., S. Sayar and S. Gunasekaran, "Application of Peleg model to study water absorption in chickpea during soaking, J. Food Eng., 53, 153-159 (2002). [ Links ]

30. Vagenas, G.K. and D. Marinos-Kouris, "The design and optimisations of an industrial dryer for Sultana raisins," J. Drying Tech., 92, 439-461 (1991). [ Links ]

31. Yadav, B.K. and V.K. Jindal, "Water uptake and solid loss during cooking of milled rice in relation to its physicochemical properties," J. Food Eng., 80, 46-54 (2007). [ Links ]

32. Zhang, M. and J. Tang, "Trends in microwave-related drying of fruits and vegetables," J. Food Sci. and Tech., 17, 634-641 (2006). [ Links ]

Received: May 27, 2010

Accepted: September 21, 2010

Recommended by Subject Editor: Ricardo Gómez