Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Latin American applied research

Print version ISSN 0327-0793On-line version ISSN 1851-8796

Lat. Am. appl. res. vol.43 no.1 Bahía Blanca Jan. 2013

Chemical, physical and typological characterization of main brazilian manganese lump ores

G.L. FARIA†, E. L. Reis‡, N. Jannotti Jr.§ and F.G.S. Araújo‡

† Rede Temática em Engenharia de Materiais, Centro, Ouro Preto(MG),CEP 35400-000, Brazil. geraldolfaria@yahoo.com.br

‡ Universidade Federal de Ouro Preto, Campus Morro do Cruzeiro, Ouro Preto(MG),CEP 35400-000, Brazil. fgabrielaraujo@uol.com.br

§ VALE - Manganês, Nova Lima (MG), CEP 34000-000, Brazil. nelson.jannotti@vale.com

Abstract— The physical, chemical and typological characteristics of manganese lump ores from three Brazilian mines, Azul, Morro da Mina and Urucum are presented herein. The chemical analysis was done by AES-ICP and titration. The typological characterization was obtained by optical microscopy and X-ray diffraction. The physical properties studied included density, surface area and porosity. The Azul, Urucum and Morro da Mina Mn contents are, respectively, 47.68, 42.69 and 28.44%. The Urucum lump ore presents the highest structural density (4.29g/cm3), followed by Azul (3.98g/cm3) and by Morro da Mina (3.56g/cm3). The Urucum, Morro da Mina and Azul bulk porosities are 22.68, 10.79 and 29.40cm3/kg, respectively. The oretypological classifications are: anhydrous-oxide for Urucum, hydrated-oxide for Azul and silicate-carbonate for Morro da Mina. The thermogravimetric analysis showed that the ore weight losses could be associated to different phenomena, depending on the ore typology.

Keywords— Manganese; Lump Ores; Brazilian Deposits; Characterization; Typological Classification.

I. INTRODUCTION

About 98% of all manganese produced in the world is used in ferromanganese alloy production, which is fully consumed by the steel industry. About 30% of the ferromanganese alloys is used for steel de-oxidation and desulphurization, and the remaining 70% for alloying effects. Most manganese found in nature is in the manganese mineral form. Materials containing manganese minerals, together with minerals formed by other elements, are known as manganese ores, which can also be called lump ores (providing their particle sizes are between 50mm and 6.3mm), or fines(if they are below 6.3mm) (Faria, 2008; Tangstad and Olsen, 1995; Olsen et al., 2007).

The manganese lump ores are largely employed as raw material for the production of ferromanganese alloys. The mixtures of these ores, originated from various mines or even different pits of the same mine, are usually defined at the ferroalloy plants solely according to their chemical and granulometric characteristics (Faria, 2008; Tangstad and Olsen, 1995).

A common problem at the operation procedure of metallurgical furnaces in the production of ferromanganese alloys is the lack of knowledge about the mineralogical and physical properties of the manganese lump ores. In this context, important parameters of the lump ores are the mineralogical constitution, porosity distribution and heat decompositions under air continuous flow, which have not been studied adequately yet.

Manganese has great economical significance in Brazil. The three main mines are Urucum, Azul and Morro da Mina (Faria, 2008). The mineralogy of manganese ores is varied and complex. Manganese occurs in more than 300 different minerals, but only a few of those have a significant amount of the element and they make up the ores of higher value. The manganese ores normally exist as oxides, hydroxides, silicates and carbonates (Tangstad and Olsen, 1995; Tangstad et al., 2004).

The Urucum manganese mine is located in the state of Mato Grosso do Sul, in the city of Corumba, near the Brazilian border with Bolivia. The manganese occurs as an oxide. Since the beginning of its exploration, this manganese mine has been one of the most important in Brazil. The terrain is sedimentary with the deposition of primary manganese oxides (Walde et al., 1981; Schobbenhaus and Coelho, 1986).

The Morro da Mina mine is located in the city of Conselheiro Lafaiete, in the metallurgical region of the state of Minas Gerais. The rocks from this mine belong to the Rio das Velhas group, identified as a vulcanic-sedimentary sequence in a greenstone belt, included in the Iron Quadrangle (Walde et al., 1981). The main products of Morro da Mina are the carbon-silicates (AMEC, 2006).

The Azul manganese mine is the largest producer of manganese ore (oxide) in Latin America, with an annual production of 2.5 Mt. The ore produced is directed mainly for the production of ferroalloys and, in a smaller scale, to the chemical and batteries industry (AMEC, 2006). The ore is characterized by its high content of hydroxides that justifies considerable weight loss in calcination procedures.

Aiming to improve the knowledge about the chemical, physical and mineralogical characteristics of these three manganese lump ores, this article presents a complete study about the chemical and mineralogical constitution, porosity distribution, and thermogravimetric behavior of them. For each ore, all of these characteristics were compared and typological classifications were proposed. This study is the first step in the beginning of a large investigative study about the intrinsic properties of manganese, aiming to optimize the selection procedures for manganese ore mixtures that compose the electrical furnace charge, focusing on manganese ferroalloy production.

This research brings an important contribution for future studies regarding the relationships between the typological classifications and metallurgical properties. There is no substantial information about these lump ores in scientific literature. The ferroalloy companies just have the chemical analysis in their internal reports, and nowadays, they are the main partners interested in this complete characterization work.

II. METHODS

One ton of manganese lump ores from each Brazilian mine (Morro da Mina (MG), Urucum (MS) and Azul (PA)) was selected, homogenized and quartered. A portion of about 50kg was sampled and classified using Tyler mesh sizes of 37.5; 19; 6.3 and 3mm, on a dry basis.

The 50kg-portions of each lump ore were again homogenized and quartered. A 10kg-sample of each ore was taken and crushed in jaw crushers until all the particles were below 6.3mm. Each crushed sample was divided in order to reserve 5kg for the chemical, physical and mineralogical characterization procedures.

For chemical and physical characterizations, the samples were pulverized in a closed disk mill, and in a pan pulverizer until all material was bellow 150#. For mineralogical characterization, 2.5kg were reserved, with particle sizes between 6.3mm and 0.4mm.

The powder chemical analysis was done by AES-ICP and titration. The physical analysis consisted in the determination of the porosimetry parameters, by nitrogen adsorption (BET), and thermogravimetry performed in a thermobalance between 27°C and 1150°C, under a continuous flow of artificial air. The heating speed was 5°C/min.

The mineralogical characterization was done by the conjugation of three different techniques. First the pulverized samples were submitted to X-ray diffraction to determine the main constituent minerals. Different ranges of particle sizes were embedded in a polymeric resin, then ground and polished. The flat surfaces were submitted for observations on their transmitted and reflected light in an optical microscope. The same samples were submitted to the EDS-MEV analysis to check the correct correspondence between the optical properties and chemical constitutions of each mineral phase. By the conjugation of these techniques, it was possible to establish a semi-quantitative mineralogical analysis, and to propose a typological classification for the studied lump ores.

III. RESULTS AND DISCUSSION

A.Chemical Characterization

Table 1 shows the chemical analysis on a dry basis of manganese lump ore yields from the Azul, Morro da Mina and Urucum mines.

Table 1. Chemical analysis of the manganese lump ores products (< 19mm >6.3mm, weigh percentages).

The studied manganese ores presented very distinct chemical characteristics. The Azul ore manganese content (47.68wt%) is the highest. The Morro da Mina sample has the lowest manganese content (28.44wt%). The Morro da Mina SiO2 content is the highest (24.59wt%) and the Azul SiO2 content is the lowest (3.16wt%). It is important to note that the iron content in the manganese lump ore from Urucum (13.85wt%) is much higher than in the others. Accordingly, it presents the lowest Mn/Fe relationship, 3.08. The highest Mn/Fe relationship, 13.3, is presented by Azul ore.

The Urucum (0.05) and Azul (0.04) lump ores present the lowest binary basicities (CaO/SiO2). These ores have these low basicities due their low CaO contents. The Morro da Mina ore presents the highest value for this parameter; around 0.21. The phosphorus content is an important parameter for the electric furnace. The greatest part of phosphorus present in ores goes to the ferroalloys and consequently to the steel, impairing their properties. The Urucum ore presents the highest phosphorus content and Morro da Mina the lowest.

According to these chemical characteristics, it is possible to affirm that Urucum, Azul and Morro da Mina ores are chemically recommended for ferroalloy production. However it is important to be aware of some important aspects. The Urucum ore has high manganese content, but also high phosphorus content. The Azul ore has the highest Mn/Fe content. The Morro da Mina ore, due to its high binary basicity, is strongly recommended for FeSiMn alloy production.

B.Mineralogical Characterization

Table 2 shows the minerals identified and semi-quantified by X-ray diffraction and optical microscopy in the Azul, Morro da Mina and Urucum manganese ores.

Table 2. Summary of the identified minerals in the lump ores from Azul, Morro da Mina and Urucum.

It is noticed that the lump ores from the Urucum and Azul mines are mainly composed of oxides with the prevalence of cryptomelane. This observation is coherent with the high manganese content in both ores. The ore from Urucum also presents other mineral constituents, such as braunite, pyrolusite, hematite, goethite and quartz. The significant presence of hematite justifies the high iron content in this ore, compared to the others. The other constituents of Azul ore are todorokite, pyrolusite, gibbsite, spessartine, magnetite and N-sutite. It is remarkable that this ore has the largest fraction of hydrated minerals.

The lump ore from Morro da Mina is composed mainly of carbonates and silicates, more specifically: rhodochrosite and spessartine. This fact is coherent with its low manganese and high SiO2 contents, compared to the others. The others minerals found are fayalite, ferrosilite, manganosite and magnetite, in addition to the amphiboles and pyroxenes.

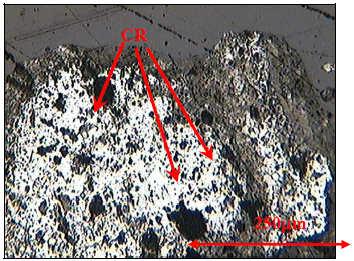

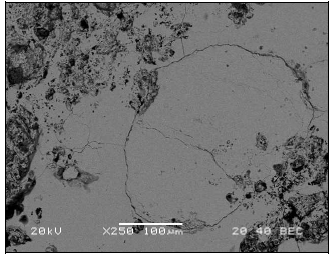

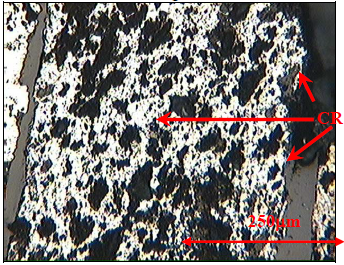

The prevailing mineral phases in the three lump ores samples studied were identified by optical microscopy and by electron microscopy combined with electron microprobe (EDS). Figure 1 presents an optical micrograph of a particle from Azul ore, which consists mainly of cryptomelane, well characterized by the white sheen. The dark spots are small holes that indicate the particle porosity. Figure 2 shows a combined image of secondary and backscattered electrons from the Azul sample, with a matrix of cryptomelane (dark grey) identified with the aid of the electron microprobe. The dark spots are also pores or cracks on the matrix surface.

Fig. 1-Particle from Azul ore. Particle constituted by cryptomelane (CR - White shining) - OM reflected light.

Fig. 2-Electron micrograph of Mn lump ore from Azul (cryptomelane matrix).

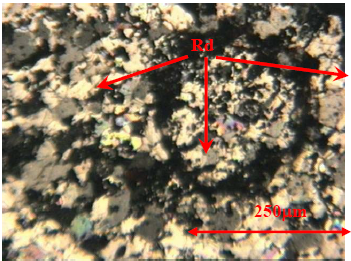

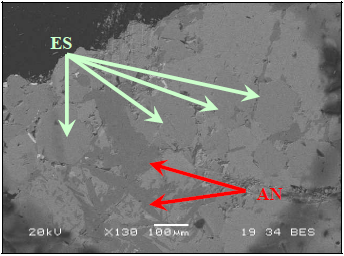

Figure 3 presents an optical micrograph of a Morro da Mina ore particle. In this figure, it is possible to see a lot of small crystals of rhodochrosite, well characterized by the pink color. Figure 4 is a combined image of secondary and backscattered electrons of the Morro da Mina sample, where grains of spessartine (ES), as well as amphiboles (AN) with an acicular aspect, can be noted.

Fig. 3-Particle from Morro da Mina ore. Particle constituted by small crystals of Rhodochrosite (Rd - little pink crystals) - OM Transmitted and Polarized Light.

Fig. 4-Electron micrograph of Mn lump ore from Morro da Mina (ES - Spessartine, AN - Amphibole).

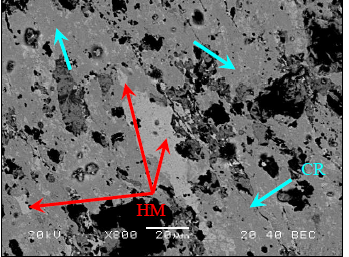

Figure 5 presents an optical micrograph of an Urucum ore particle, which is constituted mainly by cryptomelane (white sheen). Figure 6 is a combined image of secondary and backscattered electrons from the Urucum sample, where the prevalence of the cryptomelane is identified by its dark grey color, as well as the presence of hematite, characterized by lighter regions. The black regions correspond to the fissures and pores of the ore.

Fig. 5- Particle from Urucum ore. Particle constituted by cryptomelane (CR - White shining) - OM reflected light.

Fig. 6- Electron micrograph of Mn lump ore from Urucum (CR - Cryptomelane, HM - Hematite).

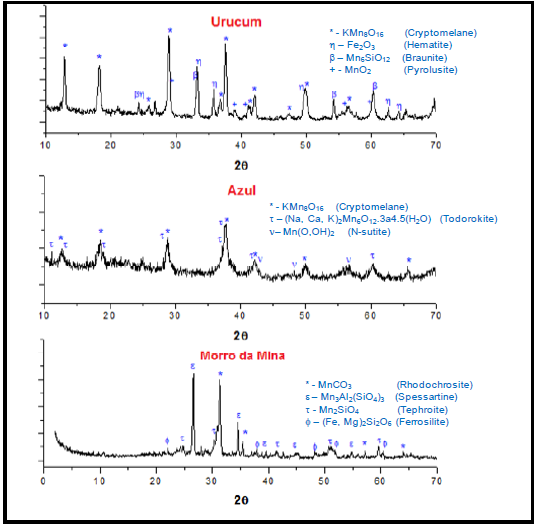

Figure 7 presents the comparison between the X-ray diffraction spectra. The main mineralogical phases are highlighted.

Fig.7- X-ray Diffraction data of ores.

C.Porosimetry

Table 3 shows the main results of surface area and porosity, measured by nitrogen adsorption for the studied manganese lump ores.

Table 3. - Main parameters defined by the BET method for the manganese lump ores from Azul, Morro da Mina and Urucum mines.

According to the data obtained with the BET method, the porosities of the studied ores show large differences. The most porous ore is the one from Azul (29.40cm3/kg) followed by Urucum (22.68cm3/kg) and then Morro da Mina (10.79 cm3/kg).

D.Thermogravimetry

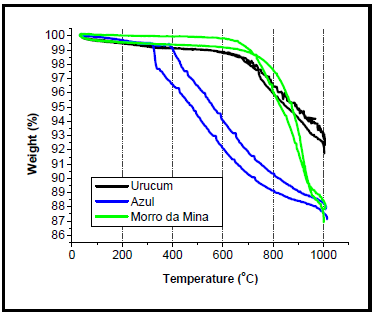

Figure 8 shows the thermogravimetric curves of the Azul, Morro da Mina and Urucum manganese lump ores. Table 4 highlights the weight loss during sample heating under continuous air flow.

Fig. 8 - Thermogravimetric curves for the ores from Urucum, Azul and Morro da Mina.

Table 4. -Average weightloss for the ore samples from Urucum, Azul and Morro da Mina

The weight loss during heating, from room temperature to 280°C, for the samples from Azul, Morro da Mina and Urucum is related to hygroscopic moisture elimination. It is important to observe that the ore from Azul mine presented the highest hygroscopic moisture content, while the ore from Morro da Mina presented the lowest moisture content.

The deep weight loss initiated around 400oC, seen on samples from Azul, is related to the beginning of the hydrated mineral-phase heat decompositions. In the Azul samples, these phases are todokorite and n-sutite. It is thought that the very slight weight loss verified around 500°C in the Morro da Mina lump ore is related mainly to the elimination of structural water, which occurs in amphiboles, superimposed to the decomposition of some carbonates originated from ion substitution in rhodochrosite.

The decomposition of some oxides (cryptomelane and pyrolusite), more specifically the transformation from MnO2 into Mn2O3, begins around 700°C in the Urucum and Azul samples. The weight variations observed in these samples (close to 1000°C) is related to the transformation of Mn2O3 into Mn3O4. The cryptomelane and pyrolusite probably turn into bixbyite (Mn2O3) between 700°C and 900°C, which, together with the braunite, begins their decomposition at 950°C, turning into a hausmannite structure (Mn3O4). The evidence for these explanations was obtained by Faria (2008) in his master's thesis.

The Azul and the Morro da Mina ores presented almost the same weight losses, which are larger than those observed for the Urucum ore. For Azul, this is partly due to its high hygroscopic moisture and to its hydrated mineral phase content. Morro da Mina ore, on the other hand, presented the lowest natural moisture content. As a whole, the most significant weight variations happened between 500°C and 800°C, and are related to the amphibole and rhodochrosite heat decompositions. For the Urucum ore, the main weight variations are related to the decomposition of its oxides.

IV. CONCLUSIONS

The manganese lump ores from Azul, Urucum and Morro da Mina showed very distinct chemical characteristics. Some of the physical characteristics of the three manganese lump ore samples are very different too. These manganese lump ores can be classified in three different typological categories according to their mineralogical compositions and to their thermogravimetric behavior. Urucum ore type is anhydrous-oxide, Azul is hydrated-oxide and Morro da Mina is hydrated-silicate-carbonate.

From the thermogravimetric tests, the weight loss of the manganese lump ores from Urucum, Morro da Mina and Azul is related to the oxides (cryptomelane, pyrolusite e braunite), carbonates (rhodochrosite) and hydrated mineralogical constituents (todorokite and amphiboles being the main ones) heat decomposition. The three studied lump ores showed different thermal behaviors during these tests.

These Brazilian manganese lump ores should be better studied for the improvement of their applications in the electrical furnace for manganese ferroalloy production. These ores present completely different chemical, physical and mineralogical characteristics and due to this, may present completely different metallurgical behaviors during the reduction procedures in this kind of metallurgical reactor.

ACKNOWLEDGE

Work supported by CNPq, FundaçãoGorceix and VALE Manganese.

REFERENCES

1. AMEC, CVRD reserve audit report, Appendix E, (2006). [ Links ]

2. Faria, G.L., Estudo da Intensidade de Crepitação de Minérios Granulados de Manganês do Brasil, Master's Thesis, Federal University of Ouro Preto, Brazil (2008). [ Links ]

3. Olsen, S.E., M. Tangstad and T. Lindstad, Production of Ferromanganese Alloys in the Submerged Arc Furnace, Trondheim, Norway (2007). [ Links ]

4. Schobbenhaus, C. and C.E.S. Coelho, Principais Depõsitos Minerais do Brasil - Volume II - Ferro e Metais da Industria do Aço. Departamento Nacional da Produção Mineral. Companhia Vale do Rio Doce (1986). [ Links ]

5. Tangstad, M. and S.E. Olsen, "The Ferromanganese Process - Material and Energy Balance," INFACON7, 621-630 (1995). [ Links ]

6. Tangstad, M., P. Calvert, H. Burn and A.G. Lindseth, "Use of Comilog Ore in Ferromanganese Production," INFACON 10, Cape Town, South Africa (2004). [ Links ]

7. Walde, D.H.G., E. Gierth and O.H. Leonardos, "Stratigraphy and mineralogy of the manganese ores of Urucum," Geologische Rundschau, 70, 1077-1085 (1981). [ Links ]

Received: July 2, 2011.

Accepted: February 24, 2012.

Recommended by Subject Editor María Luján Ferreira.