Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Anales de la Asociación Química Argentina

Print version ISSN 0365-0375

An. Asoc. Quím. Argent. vol.93 no.1-3 Buenos Aires Jan./July 2005

ELECTRONIC NOSES APPLICATIONS AND TECHNOLOGIES

Assessment of fish freshness with an electronic noseRodríguez, D.F.1; Reich, S.2*; Alonso, P3; Szudruk, M.4; Arrieta, C.5; Lacomi, H.5; Gillari, C.5 ; Boselli, A.1; Lamagna, A.1,2

1UAF, Centro Atómico Constituyentes, CNEA, 2Escuela de Ciencia y Tecnología, UNSAM, 3Investigador Independiente, 4Facultad de Ciencias Exactas, UBA, 5Dpto. Microelectrónica, CITEFA, Buenos Aires, Fax: +54 11 6772 7121, *E-Mail: silreich@cnea.gov.ar

Received November 05, 2004. In final form June 04, 2005

Abstract

In this work the performance of a prototype of electronic nose, developed in our laboratories, to assess fish freshness is analized. The present study is part of an ongoing project to perform quality assurance protocols for the Argentine fish sector, an increasing demand due to export reasons and new national food control regulations. Fish quality is a complex concept involving a whole range of factors, freshness being one of the most important. The complete quality assessment of fish meat includes information and control of all the steps, from catching area to final consumption. In this work we address one aspect, quality deterioration of “raw fillets” due to frozen storage defects.

Resumen

En este trabajo se analiza el desempeño de un prototipo de nariz electrónica, desarrollado en nuestros laboratorios para detectar el grado de conservación de la carne de pescado. El presente estudio es parte de un proyecto en marcha para crear protocolos para el control de calidad en el sector pesquero argentino, una creciente demanda debido a razones de exportación y a nuevas regulaciones locales de control vigentes. La calidad de la carne de pescado es un concepto complejo que incluye información y control de todas las etapas, desde la zona de pesca hasta su consumo final. En este trabajo tomamos sólo un aspecto, el deterioro de la calidad de carne de filetes crudos debido a fallas en el almacenamiento refrigerado.

Introduction

Control of fish freshness is of great economic relevance, as the Argentine hake is one of the most important fishes consumed. Quality assurance of raw fillets involves monitoring and documenting defined quality criteria as required by regulations. These requirements may be of different importance to the various parts of the supply and distribution chains.

During fish chilled storage, biochemical changes are known to take place, such as changes in the protein and lipid fractions and the formation of amines (volatile and biogenic) and hypoxanthine. As a consequence of these events, a deterioration in sensory quality, a loss of nutritional value and negative modifications of the physical properties of fish muscles may be expected [1]. Consequently, the time passed after catch and the temperature ‘history’ of fish is very often the key factor determining the final quality of a fish product.

Transport and storage under constant temperature conditions are supposed to be always fulfilled everywhere and thus it is generally assumed that the only relevant factor is the number of storage days. However the chilled chain may have been interrupted for some reasons and thus the spoiling process is accelerated. This is the motivation of the present work. That is to find a method for detecting abnormalities in the chilled process. Electronic noses have proved [2] to be a suitable instrument for this task.

Figure 1.

Experimental

Spoilage odours, that develop as a result of microbial growth and oxidation leading to the degradation of the tissue, are sensed by an electronic nose prototype, PampaNose 2, developed in our laboratories [3] and shown in Figure 1.

The sensor array is composed by six micromachined SnO2 sensors (low power consumption, below 50mW). Distinct electric behavior of the corresponding sensitive film is achieved through doping some of these sensors with Au and others with tetra t-Butyl Zinc Phthalocyanine. Two commercial sensors, for temperature and relative humidity control, are included inside the sensor chamber, meant keep track of these important parameters during the measurements. The electronic interface sets the temperature of the sensing film and controls the sampling and acquisition of the different signals from each sensor resistance when a given gaseous sample is present. The SnO2 thin films for the gas-sensor devices were done using the RGTO (Rheotaxial Growth and Thermal Oxidation) technique on a substrate heater element made on micro machined silicon and having a 200 nm Si3N4, membrane as a physical support of the entire sensor stack (microhot plates) [4, 5].

This micro hot plates for this work were provided by CNR-IMM Bologna, Italy. The sensor active layer of SnO2 film was selectively deposited on the central part of the membrane by means of a shadow mask. During the deposition, substrates were heated at 420 °C in high vacuum. After the thermal oxidation process, the SnO2 thickness is 200 nm.

Microscopic analysis showed the thin films were polycrystalline, with nano-structured grains, of high porosity and high specific surface area. This particular morphology exhibits a high film porosity and specific surface area, which are optimum prerequisites for sensors applications.

Fillets corresponding to the same catching area and catching date were analyzed. Samples of fresh hake were kept inside a freezer at -20 °C in closed containers. All the samples were analyzed three days after, during the first day they were taken out of the freezer and kept at ambient temperature for a given number of hours, and then taken back to the freezer.

For each measurement, 40 grams of raw fillet were taken from the refrigerator and put inside 250 cm3 glass bottles. The bottles were sealed and held at room temperature (20°C±2°C) for 20 minutes in order to reach a stable headspace composition.

The headspace was then fluxed into the e-nose sensor chamber at a flow of 200 ml/min. The nose response was registered each 0.5 minutes for a time interval of approximately 5 minutes and after that, a 10 minutes purge was done. Ambient air was used as the carrier gas. The sampled headspace and the carrier were alternately switched by a three-way valve according to this time schedule.

Results and discussion

We analyzed interruptions from the storage temperature of 3 hours, 6 hours and 24 hours, in addition to the reference samples with the same number of storage days but no freezing interruption. For each sensor signal we take only one feature, the relative normalized peak value with respect to the carrier line base. It was established elsewhere [6] that no significant improvement may be expected if more features for each sensor signal are taken into account with this nose.

For validation purposes we left aside some of the measured samples (two for each time period at ambient air), before freezing. Within this restricted space we performed an unsupervised PCA analysis. We check the performance of the PCA analysis with and without normalization of the data set. That is to say, we performed PCA using the covariance matrix (unnormalized variables) and the correlation matrix (normalized variables). The results for the case of the covariance matrix implies that the first principal component takes into account a combination of only two sensors which not only displays the greater signals but also the largest variance between the different nose responses. Use of the covariance matrix, takes into account a combination of all sensor responses for the first principal components plus that of one sensor that shows no significant signal for all the measurements.

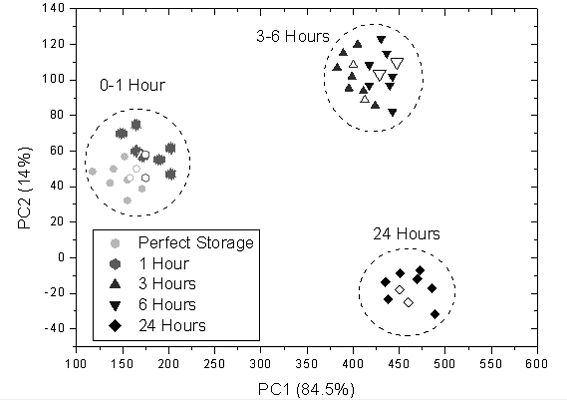

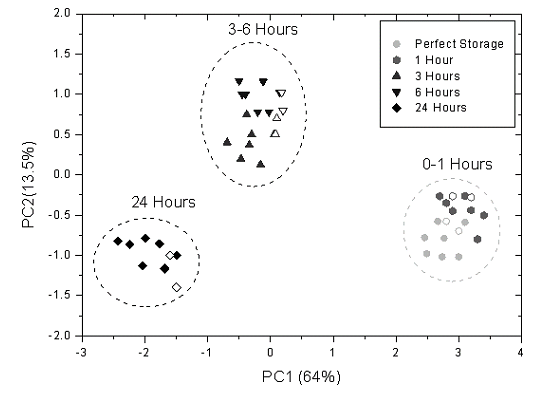

Once the classes get self organized in rather well distinguished regions, we discard outliers and validate the classification scheme using the rest of the data that was not processed. For each measurement we project the nose response onto the already defined score plane and assigned the nearest class to its corresponding transformed point. We choose to consider the distance within the PCA space approximating each cluster and thus classes were assigned taken into account the smallest residual. We obtained eight patterns out of eight correctly classified. This approach, although for only two significant principal components, is similar to SIMCA [7]. All these results are sumarized in Figure 2 and Figure 3.

The analysis show that the electronic nose detects departures from fish freshness due to interruptions in the chilled chain. There seems to be three different regions. One for fresh or up to one hour interruption in the freezing storage, other for intermediate periods between 3 to 6 hours, and a third region where samples have been left at ambient temperature for almost one day.

Although discrimination is obtained with both methods, PCA with covariance matrix gives the best results. The method is equivalent to take into account only the most significant sensors (two out of six). Larger distances are observed between clusters compared with the use of the correlation matrix PCA.

Fig. 2. Principal Component analysis of hake fillets samples with different storages times with the use of covariance matrix. In all cases empty symbols refer to the location of data used for validation.

Fig.3. Principal Component analysis of fillets samples with different storages times with the use of correlation matrix. In all cases empty symbols refer to the location of data used for validation.

Conclusions

This is a first analysis that shows the ability of an electronic nose to detect abnormalities in the temperature history during storage. The information needs to be complemented with other biochemical studies and also with panel evaluation to analize the significance of the observed departures from the reference fillet. A similar study for different storage days is in progress.

Acknowledgments

The authors wish to acknowledge support from IMM-CNR, Bologna section and financial support of J.P.A. S.A. (Javier Picco y Asoc.) through grant PID131-2001 of the National Agency for the Promotion of Science and Technology (ANPCYT) of Argentina.

References

[1] Hsieh R.; Kinsella J., Advances in Food Research and Nutrition Research 1989, 33, 233–341. [ Links ]

[2] Di Natale C.; Bruinink J.; Bungaro F.; David F.; d’Amico A.; Paolesse R.; Boschi T., Faccio M.; Ferri G., Sci. Technol. 1996, 7, 1103–1114. [ Links ]

[3] Lamagna A.; Reich S.; Negri M.; Boselli A.; Cocco M.; Di Natale C., Thin Solid Films, 2002, 418, 42-44. [ Links ]

[4] Sberviglieri G.; Faglia G.; Groppelli S.; Nelli P.; Camazzi A., Semicon. Sci. Technol. 1990, 5, 1231. [ Links ]

[5] Briand D.; Krauss A.; Van der Schoot B.; Weimar U.; Barsan N.; Gopel W.; de Rooij N.F., Sensors & Actuators B , 2000, 68, 223-233. [ Links ]

[6] Lamagna A.; Reich S.; Rodriguez D.; Scoccola N.N., Sensors & Actuators B, 2004, 102, 278-283. [ Links ]

[7] Wold, S., Pattern Recognit. 1976, 8, 127- 141. [ Links ]