INTRODUCTION

Celiac disease (CD) is a chronic and autoimmune pathology that affects multiple organs, mainly the intestine, and is related to a permanent intolerance to gluten. Within wheat endosperm proteins there are 4 fractions that are classified according to their solubility: albumins, globulins, gliadins and glutenins. Gluten is a network of proteins mainly made up of gliadins and glutenins; glutenins provide elasticity and strength to the dough, while gliadins contribute to the viscous properties and elasticity of the dough (Molina-Rosell, 2013).

At the same time, these proteins are able to stimulate the immune response in people with CD. As a result of a permanent intolerance to gluten, CD generates a severe atrophy of intestinal villi, which do not allow a correct absorption of nutrients in the intestine. In addition, being a systemic disease, it causes an abnormal immune response, which generates antibodies that can attack the whole organism, not only the intestine (Sciarini et al., 2016). This is the most frequent chronic bowel disease diagnosed in children, currently reaching positive diagnoses of between 1/100 and 1/150 of the total population of children. Although the number has been increasing in recent years, it may be related to the use of more sensitive diagnostic methods, which detect the disease earlier and/or in asymptomatic phases (Celada et al., 2018).

One of the cereals used to produce gluten-free foods is corn, since its flours do not contain gluten. Its grain has starch as its main component, which represents up to 72-73 % of its weight, the protein content can vary between 8 to 11 % and is mainly found in the endosperm. Foods made from corn have the disadvantage of having a low protein and fiber content (Brites et al., 2007).

With the approval of law No. 27,669 of the Regulatory Framework for the Development of the Medical Cannabis and Industrial Hemp Industry, which allowed the integration of Cannabis sativa L. into the agricultural production circuit, a new horizon was opened for the production of gluten-free foods (Honorable Congreso de la Nación Argentina, 2022).

Industrial hemp or Cannabis sativa L. is a fast-growing annual herb with a myriad of uses encompassing a range of products derived from the fiber and oilseed (Young, 2005). In most parts of the world where industrial hemp is authorized for cultivation, plants must not exceed a specified level of A9-tetrahydrocannabinol (THC). This compound is the main psychoactive (cannabinoid) component of the species and the restriction levels vary according to local national legislation (Small and Marcus, 2003). The vast Argentinian territory enables the extensive sowing of industrial hemp for the production of fiber, cellulose and ¡nflorescences with mainly cosmetic and pharmaceutical use. Furthermore, it is also possible to obtain seeds of high nutritional value, since they usually contain 25-35 % lipids with a good balance of fatty acids, 20-25 % easily digestible proteins rich in essential amino acids, 20-30 % carbohydrates, most of which are made up of dietary fiber, mainly insoluble, as well as vitamins and minerals. (Albarracín Flores and García Medina, 2021).

These seeds are pressed to obtain oil, which generates a residue, a dry cake of pressed seeds, which can be ground and crushed to obtain a hemp flour with all the nutritional benefits of the seeds, except for the lipid contribution.

Products for celiacs, due to the ingredients used, are generally low in protein and with high glycemic indexes (Aguiar et al., 2023), so it is necessary to improve the nutritional quality with increased protein and fiber content.

The objective of this work was to produce gluten-free noodles made from corn flour substituted with hemp flour at three different rates and to evaluate their technological quality and nutritional value.

MATERIALS AND METHODS

Materials

Corn flour was obtained from cultivar C900 (Faculty of Agricultural Sciences, National University of Córdoba FCA-UNC, for its initials in Spanish). Commercial hemp flour was provided by Hempoint (Jihlava, Czech Republic).

MethodsPhysical and Chemical characterization of flour

Whole corn kernels were milled with a cyclone mill (Cyclotec CT193, Foss, Suzhou), using a mesh to obtain wholemeal flour with a particle size of 1 mm. The samples were stored in airtight plastic bags at 4 °C until their respective determinations.

The proximate composition of protein, fiber, lipid and ash was determined according to methods 46-13.01, 32-05.01, 30-25.01 and 08-01.01 respectively (American Association of Cereal Chemists AACC, 2010).

All determinations were performed in duplicate and expressed in grams per 100 grams of dry sample.

Pasta processing

Gluten-free pastas were made by extrusion with an automatic machine for pasta production, Dolly (La Monferrina, Moncalieri, Italy), adding 2 % pregelatinized starch (Ingredion, Ciudad Autónoma de Buenos Aires, Argentina), 3 % pasteurized food-grade egg albumin (Todo Droga, Córdoba, Argentina), 1 % salt and 28 mL distilled water to obtain the control, then corn flour was replaced by 5, 10 and 15 % of hemp flour. Pasta pieces 20 cm long were obtained through conventional cold extrusion of all ingredients. The pieces were dried at 40 °C for 240 minutes in a dryer with air convection Model 600 D060602 (Memmert, Schwabach, Germany). The dried samples were stored in airtight jars at room temperature until use.

Evaluation of pasta quality

The pieces were cooked to their optimum cooking time, which was determined as the time when the white inner core of the pasta disappeared after cross-cutting it with a razor blade (according to method 16-50 AACC, 2010) and/or after compressing the pasta between two glass slides in 30 second intervals. They were evaluated for water absorption (g/100g), loss of material in cooking (g/100g) and swelling index, according to Bustos et al. (2019).

The firmness of cooked pasta was calculated from the curve obtained by 2 compressions to 50 % of two stacked 4 cm noodle strips using an Instron universal texture machine (Instron, High Wycombe, UK). Four repetitions were performed for each sample.

Color determination was performed according to Approved Methods 14-22 (AACC, 2010), using a Minolta 508d reflectance spectrophotometer, illuminant D65, 8 mm aperture, using the CIE-Lab scale, L* (lightness), a* (red-green) and b* (yellow-blue).

The protein and fiber content of the pasta was determined by the methodologies previously described.

Statistical analysis

Statistical analysis was carried out using InfoStat software (Di Rienzo et al., 2017). Results were reported as mean ± standard deviation and an analysis of variance was performed using a DLG comparison test with a significance level of p < 0.05.

RESULTS AND DISCUSSION

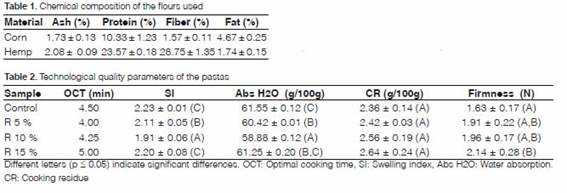

Table 1 shows the values of the composition of the flours used to carry out this study. The values obtained for all the parameters of corn flour are comparable to those published by other authors (Corcuera et al., 2016), while for hemp flour the values are in line with Alonso-Esteban et al. (2022). The results lead to the conclusion that the incorporation of hemp flour enhances the fiber and protein content of pasta.

The technological quality of pasta with hemp flour was evaluated by means of the optimum cooking time, swelling index, water absorption, cooking residue and firmness of the cooked pasta; the results obtained are presented in Table 2.

From the results of Table 2 it is observed that as the substitution of corn flour by hemp flour increases, its water absorption capacity and swelling index slightly decreases, which is due to the increase in protein content. This is because the proteins form a structure that prevents water diffusion towards the starch granules, which have a greater capacity to retain water (Flores-Silva et al. 2015). Nevertheless, as the flour composition reaches a point where proteins are fundamentally contributed by hemp, which do not have the capacity to form this structure, this trend declines. In the same way, egg proteins present in the formulation gel at temperatures below the starch gelatinization temperature; thus, a large amount of protein seem to hinder the diffusion of water inside the noodle by forming a barrier and reducing water absorption. Once hemp proteins predominate, this tendency decreases (Larrosa et al., 2015).

As for the cooking residue, no significant differences were found among the different samples (Table 2), indicating that the quality of the pastas is not deteriorated due to this factor (Bustos et al., 2019).

Table 1: Chemical composition of the flours used

In relation to firmness, an increase was observed as the replacement of corn flour by hemp flour augmented, becoming significant at higher substitution rates (Table 2).

In general, pasta of excellent quality is characterized by moderate OCT, low cooking losses, water absorption and swelling index, moderate volume increase with high firmness and chewiness but low adhesiveness (Bustos et al., 2015).

The supplemented pastas meet sought-after properties, as firm texture, low stickiness and low cooking loss are important for good quality gluten-free pasta (Susanna and Prabhasankar, 2013).

Figure 1 shows the control and the pastas obtained with the addition of the different percentages of hemp flour. The effect of flour substitution can be observed on the color. The values were determined with the surface spectrophotometer on the cooked pasta (Table 3). The most notable effect of the addition of hemp flour was on luminosity, since the L* parameter decreased significantly as the degree of substitution increased, a decrease was also observed in the red color (a*) and more notably in the yellow color (b*), in both cases maintaining positive values for these colors.

Table 3: Color parameters of pastas

Different letters (p < 0.05) indícate significant differences. L* indicates Luminosity, and a* and b* are the chromatic coordinates, the first for red (+) and green (-) and the second for yellow (+) and blue (-).

Figure 1: Photograph of raw pasta samples. Control sample and the 5 %, 10 % and 15 % replacements.

Figure 2: Percentage of protein and fiber of the control sample and the 5 %, 10 % and 15 % replacements, respectively. Different letters (p < 0.05) indicate significant differences.

CONCLUSIONS

From the results obtained, it can be concluded that the addition of 5 %, 10 % and 15 % of hemp flour to obtain gluten-free pasta does not produce a deterioration of the technological quality, while at the same time producing a significant improvement in its nutritional quality, since the fiber and protein content can be considerably increased.

Fecha de recepción: 12/07/2023

fecha de aceptación: 07/11/2023