Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista industrial y agrícola de Tucumán

On-line version ISSN 1851-3018

Rev. ind. agric. Tucumán vol.88 no.1 Las Talitas Jan./June 2011

ARTÍCULOS ORIGINALES

Assessing a sustainable sugarcane production system in Tucumán, Argentina.

Part 1: Dynamics of sugarcane harvest residue (trash) decomposition

Patricia A. Digonzelli*, Eduardo R. Romero*, Luis Alonso*, Juan Fernández de Ullivarri*, Hugo Rojas Quinteros**, Jorge Scandaliaris* and Sofia Fajre*

*Sección Caña de Azúcar, EEAOC. pdigonzelli@eeaoc.org.ar **Sección Suelos y Nutrición Vegetal, EEAOC.

Abstract

The elimination of burning practices in sugarcane harvest has led to more sustainable productive systems, with lower impact on the environment and on communities. The present paper is part of a study in which two sugarcane management systems were compared: (a) one with sugarcane harvest residue kept on the ground (trash blanketing); and (b) one without trash blanketing (burnt residue). Cultivar LCP 85-384 was planted in macro-plots in a commercial field in Albarracín, Tucumán, Argentina. A split-plot experimental design with three replications was used. Each plot had five 30 m-long rows. Two crop cycles (2006/2007 and 2007/2008), i.e. second and third ratoon, were evaluated. From the end of harvest onwards, residue amount (dry matter/ha) and residue C/N relationship were determined periodically. At the beginning and at the end of each crop cycle, residue P and K contents were assessed. Residue left after harvest amounted to 12 and 16 tons of dry matter per hectare in the first and second evaluated crop cycles, respectively, but decreased significantly throughout these periods. Residue C/N relationship was over 100 in both crop cycles (117 and 101, respectively), but decreased significantly in their course. Reductions in both sugarcane residue and C/N relationship were correlated with days after harvest and accumulated thermal time (∑ mean daily air temperature). Trash initial C concentration was similar in both crop cycles and amounted to approximately 45%, whereas initial N concentration differed (0.4% and 0.6% in second and third ratoon, respectively). Residue decomposition contributed 3800 to 5700 kg of C, 7 to 50 kg of N and 45 to 40 kg of K per ha to the agro-ecosystem in both crop cycles studied.

Key words: Sustainability; Trash blanketing; Residue decomposition.

Resumen

Evaluación de un sistema sustentable de producción de caña de azúcar en Tucumán, R. Argentina.

Parte I: Dinámica de la descomposición del residuo de la cosecha en verde de la caña de azúcar

La eliminación de la quema durante la cosecha de la caña de azúcar llevó a la implementación de sistemas productivos más sustentables, con menos impacto ambiental y más amigables con las poblaciones vecinas. El presente trabajo forma parte de un estudio donde se compararon dos sistemas de producción de caña de azúcar: a) manteniendo la cobertura de residuos de cosecha (RAC) sobre el suelo y b) sin cobertura de residuos de cosecha (residuo quemado). Se establecieron macroparcelas en un lote comercial implantado con el cultivar LCP 85-384, en la localidad de Albarracín, Tucumán, República Argentina. El diseño experimental fue de parcelas divididas con tres repeticiones; cada parcela estuvo formada por cinco surcos de 30 m. Las evaluaciones se hicieron en dos ciclos agrícolas: 2006/2007 y 2007/2008 (segunda y tercera soca). A partir de la cosecha, se determinó periódicamente la cantidad de RAC (materia seca/ha) y la relación C/N del RAC. En el comienzo y fin de cada ciclo se evaluó el contenido de P y K del residuo. La cantidad de residuo después de la cosecha fue de 12 y 16 t de materia seca/ha para cada ciclo agrícola, respectivamente. Esta cantidad decreció significativamente desde el comienzo hacia el fin de cada ciclo. La relación C/N del RAC fue superior a 100 en ambos ciclos (117 y 101, respectivamente), pero se redujo significativamente hacia el fin de cada ciclo. La disminución de la cantidad de RAC y de la relación C/N estuvo correlacionada con los días transcurridos desde la cosecha y con la temperatura (suma térmica). La concentración inicial de C del RAC fue similar en ambos ciclos (aproximadamente 45%), mientras que la concentración inicial de N fue más variable entre los ciclos considerados (0,4% y 0,6%, respectivamente). La descomposición del RAC aportó al agroecosistema entre 3800 y 5700 kg de C/ha, 7 y 50 kg de N/ha y 45 y 40 kg de K/ha, en cada ciclo agrícola estudiado.

Palabras clave: Sustentabilidad; Cosecha en verde; Descomposición del residuo.

Introduction

Burning sugarcane plantations before or after harvest has been a widely common practice for years in Tucumán, Argentina, as well as in many other sugarcane production areas. However, this practice causes several problems. In fact, it deprives the soil of vegetal residue and, associated to storage, results in significant sugar losses, affects factory process and deteriorates both the environment and the quality of life of people living near sugarcane fields. Finally, accidental or uncontrolled burnings can affect neighboring fields and electric energy supply (Delgado, 1985; Olea y Scandaliaris, 1994; Graham et al., 2002; Kingston et al., 2005; Johnson et al., 2007; Núñez and Spaans, 2007; Romero et al., 2007 and Robertson and Thorburn, 2007). Therefore, the suppression of sugarcane burning and the implementation of green cane harvesting are mandatory if management systems are to be more friendly to people, have a lesser impact on the environment and lead to sustainable sugarcane production.

When sugarcane is harvested without burning, a large amount of residue (leaves and tops), representing 7 to 30 tons of dry matter per hectare, is retained on the ground (Furlani Neto et al., 1997; Oliveira et al., 1999a and b; Thorburn et al., 2001; Souza et al., 2005; Robertson and Thorburn, 2007; Núñez and Spaans, 2007; Romero et al., 2009). This amount depends on variety and mostly on plot productivity level (Romero et al., 2009). Residues can be either left on the ground as a cover (mulching), blended with the first centimeters of soil profile, or partially removed from the field by means of a round baler (Digonzelli et al., 2006 and Digonzelli et al., 2007).

Some of the most noticeable consequences of keeping crop residues in the field are the following: residue increases both organic matter contents and soil structural stability, allows nutrient recycling, helps keeping soil humidity, reduces soil water evaporation, improves soil water infiltration, reduces erosion, diminishes sudden changes in soil temperature range, increases beneficial microorganism population, diminishes weed infestation, and allows skipping certain cultural practices (Wood, 1991; Prove et al., 1995; Graham et al., 1999; Braunack and Ainslie, 2001; Graham et al., 2002; Thorburn et al., 2004; Kingston et al., 2005; Souza et al., 2005; Meier et al., 2006; Núñez and Spaans, 2007; Romero et al., 2007 and Sanzano et al., 2009).

When residue is retained on the ground, neither adverse effects on both cane and sugar yields, nor problems in crop management, are observed. On the contrary, in many sugar cane areas, except in those which are very humid and/or display low temperatures, the results have been satisfactory. In effect, a better conservation of humidity and the increase in organic matter due to residue retention have resulted in more rapid cane growth and greater sugar cane yields (Wood, 1985; Wood, 1986; Van Antwerpen et al., 2001). Several studies carried out with simulation models have proved that trash blanketing management rose the level of soil organic matter by almost 40% in 60 years. Almost half of that increment was achieved in the first 20 years (Vallis et al., 1996).

Sugarcane residue contains a considerable amount of nutrients. When sugar cane trash is burnt, before or after harvest, between 70% and 90% of nitrogen, carbon and other nutrients are delivered to the atmosphere (Mitchell and Larsen, 2000; Thorburn et al., 2004). On the contrary, when trash is retained, organic matter and nutrients remain. Thus, studies by Wood (1991), Chapman et al. (1992) and Robertson (2003) suggest an increase in both total N and C and soil organic matter content under trash blanketing conditions.

Currently, approximately 80% of the sugarcane area in Tucumán is harvested with combine harvesters and over 90% of that harvest is carried out without burning. However, the percentage of green harvested area, where residue is burnt after harvest, is still high (approximately 70%) (Scandaliaris, 20091). Sugarcane growers burn straw after green harvest because they fear that later intentional or accidental burning may affect the already emerged shoots.

To change this situation, it is necessary to study the dynamics of both residue decomposition and nutrient release and analyze the beneficial effects of trash blanketing on different soil and crop parameters. Such are the aims of this paper. The information presented will help decide, under local conditions, whether it is more convenient to retain trash or find another residue management strategy. Also, some information about straw nutrient recycling can be useful for recommendations on the use of fertilizers.

Materials and methods

The trial was conducted in Albarracín, Department of Cruz Alta, Tucumán, Argentina (26º47'41'' LS and 64º59'10'' LW). Albarracín is located in the eastern border of the sub-humid-humid Chaco-Pampeana plain. Mean annual temperature is 19ºC and mean annual rainfall ranges from 750 to 800 mm. Water deficit, which is a climatic limitation for sugarcane growing, is moderate from August to October. Soils in the east of the region are typic Argiustoll with silty loam texture over the surface, and are moderately well drained. Their pH is 6.6; organic matter content, 2%; exchangable K, 1.7 cmol c kg-1 and CEC, 17 cmol c kg-1 (Sanzano y Fadda, 2009).

The cultivar used in the trial was LCP 85-384, the most widely grown in Tucumán, as it covers more than 65% of the sugarcane area in the province (Cuenya et al., 2009). The assessments were made during two crop cycles: 2006/2007 and 2007/2008 (second and third ratoon). The former lasted 230 days, from the end of harvest in November 2006 to July, when the new harvest started. The latter took 322 days, from July 2007 to June 2008.

The agronomic management of the plots consisted of practices tipically carried out in the area. These included weed control with post-emergence herbicides, nitrogen fertilization (applying urea manually at a 115 kg ha-1 rate) in late November 2006 and in mid-November 2007, and no irrigation.

A split-plot experimental design with three replications was used. Each plot had five 30-m-long rows, where 10 m-long fixed sampling stations were set up to count the number of stalks periodically. The plots were harvested without burning, using a combine harvester. The sugarcane production systems evaluated were a) management with trash blanketing and b) management without trash blanketing. In plots where the second management system was to be evaluated, residue was burnt immediately after harvest. During the 2006/2007 and 2007/2008 crop cycles, assessments were carried out every 20 to 30 days. Assessed parameters were the following:

(a) Amount of residue: for this purpose, a one-meter iron square was used and all the residue on its surface was collected. Three subsamples were taken at random in each plot and fresh weight was determined. The material was heated at 70ºC until dry weight was reached.

(b) Residue C/N relationship: a sample was taken per plot and organic carbon was determined by using the Walkley and Black method, while total N was determined with the Kjeldahl method.

(c) Residue P and K contents: they were determined by means of colorimetric method and photometry, respectively, at the beginning and end of each crop cycle.

For statistical analysis, an ANOVA with fixed effects was used, and comparisons of means were performed by using the Tukey test with a 5% probability. Linear regression analyses were also performed. Accumulated thermal time (∑ temperature) was calculated by adding mean daily air temperature from harvest day onwards, without subtracting the base temperature, as temperatures did not fall below 0ºC, in accordance with Douglas and Rickman's (1992) and Robertson and Thorburn's (2007) methodologies.

Results and discussion

1. Sugarcane harvest residue decomposition

Table 1 shows the amount of residue, expressed as tons of dry matter per hectare, at the beginning and end of the two crop cycles studied. Both the amount of decomposed residue and decomposition percentage are shown.

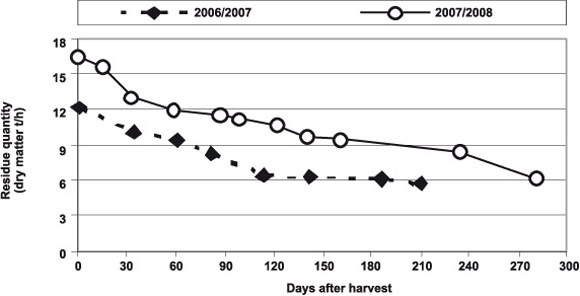

In both crop cycles, the amount of residue left on the ground after green-cane harvesting was high but decreased significantly throughout, so it could be managed easily at the end of each period.

Initial and final trash amounts were similar in both crop cycles, whereas decomposition percentages were 53.6% and 63.8% in the 2006/2007 and 2007/2008 seasons, respectively (Table 1).

Table 1. Initial and final amounts of residue, decomposed residue and decomposition percentage in the 2006/2007 and 2007/2008 crop cycles. Albarracín, Tucumán, Argentina.

Figure 1 shows residue amount evolution in tons of dry matter per hectare, throughout the crop cycles under consideration.

Figure 1. Residue amount evolution in the two evaluated crop cycles. Albarracín, Tucumán, Argentina.

According to several studies, the amount of residue remaining on the ground after green-cane harvesting varies between 6 and 30 tons of dry matter per hectare (Wood, 1991; Furlani Neto et al., 1997; Mitchell and Larsen, 2000; Thorburn et al., 2001; Oliveira et al., 2002; Faroni et al., 2003 and Basanta, 2004). The amount of residue determined in the present study (12 and 17 tons per hectare) is similar to that found by Rípoli et al. (1991), Spain and Hodgen (1994), Oliveira et al. (1999a and b), Souza et al. (2005), Núñez and Spaans (2007), Robertson and Thorburn (2007) and Romero et al. (2009), in sugar cane plantations in Brasil, Ecuador, Australia and Argentina.

In experiences carried out in Tucumán, Romero et al. (2009) determined that potential dry trash remaining in fields after green-cane harvesting ranged from 7 to 16 tons per hectare. This amount depended on sugar cane variety and mainly on production levels. The amount of residue rose with increase in production, whereas its vegetative composition changed (leafy content decreased while millable stalk share increased).

The authors also determined a mean dry residue amount of 15 tons per 100 tons of sugarcane (Romero et al., 2009). Mitchell and Larsen (2000) and Robertson and Thorburn (2007) found residue mean values of 10 tons per 100 tons of sugarcane.

In Brazil, Oliveira et al. (1999a and b) reported a residue decomposition percentage close to 70% after eleven months in the field. Faroni et al. (2003) determined a trash reduction of 52% to 58% after a year, a result very similar to the ones obtained in the present study. On the other hand, Oliveira et al. (2002) reported that the amount of residue decreased by 22% in one environment, and 70% in another in a year. These authors considered that differences in residue decomposition percentages between the two environments were related to both lower lignine contents in residues and irrigation used in the environment with higher decomposition. In Australia, Spain and Hodgen (1994) reported 81% of residue decomposition for a period of almost a year. Thorburn et al. (2001) and Robertson and Thorburn (2007) reported residue decomposition percentages ranging from 80% to 98% after 12 months in the field, at different sites in Australia.

Residue decomposition significantly correlated with days after harvest and accumulated thermal time (∑ mean daily air temperature). Residue dry matter reduction was exponential in the 2006/2007 crop cycle and lineal in the 2007/2008 crop cycle (Figure 2a and b). Residue decomposition showed a linear relationship with accumulated thermal time in both crop cycles assessed (Figure 3a and b). Similar results were reported by Thorburn et al. (2001) and Robertson and Thorburn (2007).

Figure 2. Dry matter residue reduction as a function of days after harvest: a) 2006/2007 and b) 2007/2008. Albarracín, Tucumán, Argentina.

Figure 3. Dry matter residue reduction as a function of accumulated thermal time: a) 2006/2007 and b) 2007/2008. Albarracín, Tucumán, Argentina.

Katterer et al. (1998) indicated that carbon mineralization rate doubles every time temperature increases 10ºC in the 5ºC-35ºC interval. Thorburn et al. (2001) pointed out that 35ºC is the optimum temperature for sugarcane harvest residue to decompose. Robertson and Thorburn (2007) found a linear relationship between accumulated thermal time and sugarcane residue decomposition at several sites in Australia. These authors pointed out that this significant correlation between temperature and residue decomposition can be observed in those places where residue decomposition is partially limited by temperature, which is the case of Tucumán. This type of linear relationship between temperature and residue decomposition was also observed by Douglas and Rickman (1992) at several sites in the USA, in residues with high C/N relationship. The positive association between temperature and residue decomposition was also mentioned by Oliveira et al. (1999 a and b) and Ernst et al. (2002).

2. Residue C/N relationship

Table 2 shows residue C/N relationship immediately after harvest and at the end of each crop cycle, while also displaying its reduction percentage.

In both crop cycles, fresh residue C/N relationship was high (over 100). Residue initial and final C/N relationship was similar in the two crop cycles under study. At the end of both crop cycles, trash C/N relationship dropped significantly as a consequence of residue mineralization. Reduction percentages were 65.6% and 52.2% in 2006/2007 and 2007/2008, respectively (Table 2). Figure 4 shows the evolution of residue C/N relationship in the two crop cycles under consideration.

Table 2. Residue initial and final C/N relationship and reduction percentage of C/N relationship in the two evaluated crop cycles. Albarracín, Tucumán, Argentina.

Figure 4. Evolution of residue C/N relationship in the two crop cycles under study. Albarracín, Tucumán, Argentina.

Oliveira et al. (1999a and b) found a C/N relationship of 97 and 94 for fresh sugarcane residue at two Brazilian sites. Thorburn et al. (2001) and Faroni et al. (2003) reported values of around 100, and Robertson and Thorburn (2007) found C/N relationships ranging from 70 to 117 at different Australian sites. These results are similar to the ones presented here. By contrast, Spain and Hodgen (1994) reported a sugarcane residue C/N relationship of 170.

In accordance with the results shown in this paper, Spain and Hodgen (1994) found that C/N relationship diminished by 55% in 338 days, whereas Olivera et al. (1999a and b) reported a reduction ranging from 38% to 56% throughout a similar period. Faroni et al. (2003) cited a reduction of 50% to 60% in residue C/N relationship after a year, whereas Robertson and Thorburn (2007) reported reductions by 57% to 66% at several Australian sites.

Residue degradation speed and probable release of nutrients are mainly determined by residue C/N relationship and N, lignine and poliphenoles contents (Vigil et al., 1991; Seneviratne, 2000; Robertson and Thorburn, 2007).

Many authors established that critical C/N relationship values are between 20 and 40. Therefore, crop residue decomposition with high C/N ratios (> 40) is expected to be slow due to limited N availability (Alexander, 1977; Myers et al., 1994; Seneviratne, 2000; Morón, 2000). In effect, results of the present study show that sugarcane residue is a residue with a low mineralization rate.

In the present study, residue C/N relationship was between 40 and 50 at the end of both crop cycles. In Brazil, Oliveira et al. (1999a and b) indicated C/N relationship values between 41 and 68 when the residues had remained in the field for a year. For the same period of time, Faroni et al. (2003) cited values between 34 and 42, and Robertson and Thorburn (2007) reported values between 30 and 40 for different Australian sites. Meanwhile, Spain and Hodgen (1994) reported a sugarcane residue C/N relationship of 78 after a period of almost a year.

Residue C/N relationship reduction was significantly correlated with days after harvest and accumulated thermal time (Figure 5a and b, and Figure 6a and b). These results show clearly that temperature is a key factor in controlling organic matter decomposition, as it was reported in papers by Stanford et al. (1973), Stott et al. (1986); Oliveira et al. (1999a and b), and Thorburn et al. (2001).

Figure 5. Residue C/N relationship reduction as a function of days after harvest: a) 2006/2007 and b) 2007/2008. Albarracín, Tucumán, Argentina.

Figure 6. Residue C/N relationship reduction as a function of accumulated thermal time: a) 2006/2007 and b) 2007/2008. Albarracín, Tucumán, Argentina.

However, temperature is not the only important factor controlling residue decomposition. In fact, water availability, residue-soil contact, residue chemical composition (C/N relationship, lignine and polyphenol contents), soil texture, as well as soil micro flora and micro fauna, are some of the main elements that account for residue decomposition process (Stott et al., 1986; Seneviratne, 2000; Magid et al., 2006 and Robertson and Thorburn, 2007).

3.- C, N, P and K contents in sugar cane green harvest residue

Residue initial C concentration, expressed as percentage of dry matter, was similar in both crop cycles: 45% in 2006/2007 and 49% in 2007/2008. At the end of each crop cycle, residue C concentration was 29% and 25%, respectively (Figure 7). C concentration values found in the present study are similar to those cited by Rípoli et al. (1991), Spain and Hodgen (1994), Trivelin et al. (1995), Oliveira et al. (2002) and Robertson and Thorburn (2007).

Figure 7. Initial and final C and N contents of residue (% dry matter) for the two crop cycles considered. Albarracín, Tucumán, Argentina.

Different letters between initial C vs. final C and initial N vs. final N indicate significant differences (p<= 0.05).

Residue initial N concentration (% dry matter) was more variable than C concentration in both crop cycles, with 0.39% in 2006/2007 and 0.56% in 2007/2008 (Figure 7). N contents are expected to be more variable, as sugarcane harvest residue consists of variable proportions of live and dead leaves and tops, all of which have different N concentrations. Similar results were reported by Trivelin et al. (1995), who cited initial N concentrations between 0.46% and 0.65% in sugar cane residue. Oliveira et al. (2002) also reported 0.46% and 0.54% N concentration in fresh sugar cane residue; Robertson and Thorburn (2007) found values of 0.38% and 0.67% at different Australian sites, and Spain and Hodgen (1994) cited 0.26%, a lower value than the ones reported in this paper.

At the end of both crop cycles, residue N concentration reached 0.73% and 0.67%, respectively, but this increment was significant only for the 2006/2007 cycle (Figure 7).

This behaviour has also been reported for other residues with high C/N relationship. Thus, Sánchez et al. (1996) estimated N concentration increments for corn trash decomposing on the ground. Ernst et al. (2002) reported wheat trash behaving in the same way. Morón (2000) reported similar results for sorghum cane trash buried in the soil, and emphasized the importance of N immobilization due to microorganisms, especially fungi. N concentration increase in residue decomposing in the soil is due to residue weight loss and additional N immobilization by soil microorganisms (Sánchez et al., 1996 and Ernst et al., 2002). In turn, in residues with high C/N relationship, nitrogen is released more slowly than carbon during the decomposition process. Therefore, residue N concentration increases as decomposition process advances (Schomberg et al., 1994 and Ernst et al., 2002). Basanta et al. (2003) and Thorburn et al. (2004) also reported potential N immobilization during sugarcane harvest residue decomposition. On the other hand, Schomberg et al. (1994) demonstrated that wheat trash on soil surface, when not buried, favored N immobilization for long periods of time, while N percentage in the residue increased as compared to the initial percentage. These results are consistent with those reported in this study for sugarcane residue left in the field. Figure 8 shows N concentration evolution in sugarcane residue through the two crop cycles studied.

Figure 8. Productos de la amplificación por PCR en el diagnóstico de escaldadura de la hoja, en muestras de plantines micropropagados. Calles 1-10 y 14-24: muestras analizadas; 11: marcador de peso molecular; 12: control positivo y 13: control negativo.

Sugarcane residue contains important quantities of N; however, the high residue C/N relationship results in an initial immobilization of soil mineral N and provision of little N available for crop uptake in the first year. In the short term, sugarcane trash is an N source of slow availability to the crop. However, in the long term trash retention improves soil N fertility (Wood, 1991, Mitchell et al., 2000; Basanta et al., 2003; Thorburn et al., 2005 and Meier et al., 2006).

Therefore, the decrease in residue C/N relationship was due to C concentration reduction and N concentration increase.

Considering residue amount and C content (% dry matter), trash returned to the soil after harvest contained 5457 kg and 8090 kg of C per hectare in 2006/2007 and 2007/2008, respectively. At the end of the crop cycles, 1661 kg and 2360 kg of C per hectare remained in the trash in 2006/2007 and 2007/2008, respectively. These values indicate that there was an effective contribution of 3796 kg and 5730 kg of C per hectare to the agro-ecosystem in each crop cycle.

Similarly, trash after harvest contained 47.5 kg and 92.4 kg of N per hectare in 2006/2007 and 2007/2008, respectively. After each crop cycle, 41.2 kg and 40.5 kg of N per hectare remained in the trash.

In other words, at the end of both crop cycles the agro-ecosystem received approximately 70% of residue original C. In the case of N, by the end of the 2006/2007 cycle, only 13% of residue original N had been received by the agro-ecosystem, whereas 56% had been contributed in the 2007/2008 cycle. The differences between the two crop cycles can be attributed to different residue decomposition rates and residue chemical composition differences (C/N relationship, initial N concentration, poliphenol/ N ratio and lignine content, among other important factors).

Van Antwerpen et al. (2001) in South Africa reported 20 t of residue per hectare with an initial content of 150 kg of N per hectare.

Graham et al. (2002) reported an annual contribution of 4000 to 7700 kg of C per hectare when residues were left in the field.

Oliveira et al. (2002) reported a potential sugar cane residue contribution of 6260 kg of C/ha and 64 kg of N/ha in Brazil. After a year in the field, 3640 kg of C/ha (58% of the original C) and 53 kg of N/ha (83% of the original N) remained in the residue.

Robertson and Thorburn (2007), working at different sites in Australia, found values between 3000 kg and 5000 kg of C/ha, and 27 kg to 55 kg of N/ha, in sugarcane harvest residue. These authors reported the release of 84% to 98% of original C and between 67% and 95% of original N after a year.

Figure 9 shows residue P and K contents (% dry matter), at the beginning and end of each crop cycle. Initial and final P concentration in residue for both cycles was similar, showing no variations between the beginning and the end of the crop cycles (between 0.05% and 0.06%).

Figure 9. Initial and final P and K contents in residue (% dry matter) in the two crop cycles considered. Albarracín, Tucumán, Argentina.

Residue initial K concentration was similar in both cycles (0.47% and 0.36%, respectively) and diminished significantly between initial and final assessments.

Considering residue K concentration and residue amount (dry matter) for each crop cycle, trash returned to the soil after harvest contained 57.2 and 59.8 kg of K/ha in 2006/2007 and 2007/2008, respectively.

Wood (1991) found a K concentration of 0.51% in sugar cane harvest residue, which represented an initial content of 86 kg of K/ha.

Spain and Hogen (1994) found P and K concentrations of 0.04% and 0.61%, respectively, in sugarcane harvest residue. In the case of K, this meant an initial content of 96.6 kg/ha.

In two different experiences in Brazil, Oliveira et al. (2002) reported a residue initial K concentration of 0.47% and 0.66%, respectively. These values represented 66 kg and 138 kg of K/ha.

In the present experience, at the end of each crop cycle 78.7% and 66.7% of residue K contents were released in 2006/2007 and 2007/2008, respectively. K levels released were high due to the fact that this element is found in plants as ions, without making up any compound. Therefore, when the plasmatic membrane of the cells was broken, K spread easily.

In agreement with these results, Yaday et al. (1987) found a release of 70% of K from sugarcane residue after 120 days of incubation at 28°C. Spain and Hogen (1994) reported the release of 79% of residue K contents in 338 days, while P concentration remained unchanged. In an assay carried out under irrigation, Oliveira et al. (1999a) found a release of 93% of K and over 60% of P from sugarcane residue after eleven months. These results differ from the ones reported in this paper, especially in connection with P release. The authors suggested that irrigation had probably influenced residue nutrient release. In another assay carried out without irrigation at a different site in Brazil, Oliveira et al. (1999b) found K release values of 85% (56 kg of K/ha), while P levels remained unchanged from the beginning to the end of the period under consideration (one year). The release of 78.7% and 66.7% of K contents from the residue in the present study represented an effective contribution of 45.1 kg and 39.9 kg of K/ha in 2006/2007 and 2007/2008, respectively. In the sugarcane areas where K fertilization is required, which is not the case of Tucumán, straw K rapid release has practical implications in crop nutrition and allows decreasing K fertilization doses for the next sugarcane ratoon.

Conclusions

The quantity of residue from green-harvested sugarcane is high, but decreases significantly at the end of each crop cycle to an amount that can be managed easily in the field.

Sugarcane trash presents a high C/N relationship, which indicates that this residue undergoes a slow mineralization process. This work revealed that C/N relationship decreased significantly along crop cycle, and this decrease, together with that in residue amount, was significantly correlated with days after harvest and accumulated thermal time, the latter being a crucial factor regarding the control of residue decomposition.

Residue initial C concentration was similar in the two crop cycles, whereas residue initial N concentration differed more from one cycle to the other.

Residue decomposition implies that the agro-ecosystem receives C, N and K supplies, which has practical implications in crop nutrition and hence, fertilization practices. In the medium or long term, trash blanketing management can be expected to improve sugarcane plantation productivity.

Acknowledgments

We are grateful to Agr. Eng. Mariano Abregú (J. J. Budeguer Company) for cooperating with our assay.

Cited references

1. Alexander, M. I. H. 1977. Introduction to soil microbiology. John Wiley & Sons (ed.), New York, USA. [ Links ]

2. Basanta, M. 2004. Dinámica do nitrogenio en la cultura de cana-de-açucar em diferentes sistemas de manejo de resíduos da colheita. Escola Superior Luiz de Queiroz, Universidade de Sao Paulo, Brasil. [On line]. Available at http://www.teses.usp.br/teses/disponiveis (accessed 7 December 2009). [ Links ]

3. Basanta, M.; D. Dourado-Neto; K. Reichardt; O. O. S. Bacchi; J. C. Oliveira; P. C. Trivelin; L. C.Timm; T. T. Tominaga; V. Correchel; F. A. Cassaro; L. F. Pires and J. R. De Macedo. 2003. Management effects on nitrogen recovery in a sugarcane crop grown in Brazil. Geoderma 116: 235-248. [ Links ]

4. Braunack, M. and H. Ainslie. 2001. Trash blankets and soil physical properties: Mackay experience. Proc. Aust. Soc. Sugar Cane Technol. 23: 154-160. [ Links ]

5. Chapman, L.; M. Haysom and P. Saffigna. 1992. N cycling in cane fields from 15N labelled trash and residual fertiliser. Proc. Aust. Soc. Sugar Cane Technol. 14: 84-89. [ Links ]

6. Cuenya, M. I.; S. Ostengo; E. R. Chavanne; M. A. Espinoza; D. D. Costilla y M. A. Ahmed. 2009. Relevamiento de la distribución de variedades comerciales y de la aplicación de otras tecnologías en el área de cultivo de caña de azúcar de la provincia de Tucumán: campaña 2007-2008. Gac. Agroindustrial EEAOC (72). [ Links ]

7. Delgado, A. A. 1985. Os efeitos da queima dos canavais. STAB-Açucar, Alcool e Subproductos 3 (6): 42-45. [ Links ]

8. Digonzelli, P.; L. Alonso; S. Casen; J. Giardina; E. R. Romero; M. F. Leggio Neme; J. Scandaliaris; J. Alonso; J. Fernández de Ullivarri y J. Tonatto. 2006. Manejo de los residuos de la cosecha en verde de la caña de azúcar: evaluación preliminar de máquinas enfardadoras. Avance Agroind. 27 (4): 25-27. [ Links ]

9. Digonzelli, P. A.; J. Scandaliaris; M. J. Tonatto; J. A. Giardina; S. D. Casen; M. F. Leggio Neme y E. R. Romero. 2007. La caña verde: un aporte a la sustentabilidad de la producción de caña de azúcar. II- Alternativas y equipos para el manejo del cañaveral sin quema. Avance Agroind. 28 (4): 16-20. [ Links ]

10. Douglas, C. L. and R. W. Rickman. 1992. Estimating crop residue decomposition from air temperature, initial nitrogen content, and residue placement. Soil Sci. Soc. Am. J. 56: 272-278. [ Links ]

11. Ernst, O.; O. Betancur y R. Borges. 2002. Descomposición de rastrojo de cultivos en siembra sin laboreo: trigo, maíz soja y trigo después de maíz o soja. Agrociencia 6: 20-26. [ Links ]

12. Faroni, C. E.; A. C. Vitti; G. J. C. Gava; C. S. Manzoni; C. P. Penatti e P. C. O. Trivelin. 2003. Degradação da palha (15N) de cana-de-açúcar em dois anos consecutivos. In: Anais Congresso Brasileiro de Ciência do Solo, 29, Ribeirão Preto, Brasil [CD-ROM]. [ Links ]

13. Furlani Neto, V. L.; T. C. Ripoli e N. A. Villa Nova. 1997. Biomassa de cana-de-açucar: energia contida no palhiço remanescente de colheita mecânica. STAB- Açucar, Alcool e Subprodutos 15 (4): 24-27. [ Links ]

14. Graham, M. H.; R. J. Haynes and J. H. Meyer. 1999. Green cane harvesting promotes accumulation of soil organic matter and an improvement in soil health. Proc. S. Afr. Sug. Technol. Ass. 73: 53-57. [ Links ]

15. Graham, M. H.; R. J. Haynes and J. H. Meyer. 2002. Changes in soil chemistry and aggregate stability induced by fertilizer applications, burning and trash retention on a long-term sugarcane experiment in South Africa. Eur. J. Soil Sci. 53: 589-598. [ Links ]

16. Johnson, R. M.; R. P. Viator; M. P. Grisham; E. P. Richard and R. Boopathy. 2007. Microbial degradation of post-harvest residues, In: Proc. ISSCT Congress, 26, Durban, S. Africa, 2007, pp. 365-373. [ Links ]

17. Katterer, T.; M. Reichstein; O. Andrén and A. Lomander. 1998. Temperature dependence of organic matter decomposition: a critical review using data analyzed with different models. Biol. and Fertil. Soils 27 (3): 258-262. [ Links ]

18. Kingston, G.; J. L. Donzelli; J. H. Meyer; E. P. Richard; S. Seeruttun; J. Torres and R. Van Antwerpen. 2005. Impact of green cane harvest and production system on the agronomy of sugarcane. In: Proc. ISSCT Congress, 25, Guatemala, 2005, pp. 521-533. [ Links ]

19. Magid, J.; A. De Neergaard and M. Brandt. 2006. Heterogeneus distribution may substantially decrease initial decomposition, long-term microbial growth and N-inmobilization from high C-to-N ratio resources. Eur. J. Soil Sci. 57: 517-529. [ Links ]

20. Meier, E.; P. J. Thorburn; K. Wegener and K. Basford. 2006. The availability of nitrogen from sugarcane trash on contrasting soils in the wet tropics of North Queensland. Nutr. Cycl. Agroecosyst. 75: 101114. [ Links ]

21. Mitchell, R. D. J. and P. Larsen. 2000. A simple method for estimating the return of nutrients in sugarcane trash. Proc. Aust. Soc. Sugar Cane Technol. 22: 212-216. [ Links ]

22. Mitchell, R. D. J.; P. J. Thorburn and P. Larsen. 2000. Quantifying the loss of nutrients from the inmediate area when sugarcane residues are burnt. Proc. Aust. Soc. Sugar Cane Technol. 22: 206-211. [ Links ]

23. Morón, A. 2000. El rol de los rastrojos en la fertilidad del suelo. Documentos Online. 030. [On line]. Available at www.inia.org.uy/online/ (accessed 2 December 2009). Instituto Nacional de Investigación Agropecuaria Uruguay. [ Links ]

24. Myers, R. J. K.; C. A. Palm; E. Cuevas; I. U. N. Gunatilleke and M. Brossard. 1994. The synchronization of nutrient mineralization and plant nutrient demand. In: Woomer, P. L. and M. J. Swift (eds.), The biological manangement of tropical soil fertility, Chichester, UK J. Wiley, pp. 81-116. [ Links ]

25. Núñez, O. and E. Spaans. 2007. Evaluation of green-cane harvesting and crop management with trash-blanket. In: Proc. ISSCT Congress, 26, Durban, Sudáfrica, pp. 131-142. [ Links ]

26. Olea, I. y J. Scandaliaris. 1994. Manejo racional del fuego en la cosecha de la caña de azúcar. Avance Agroind. 53: 28-31. [ Links ]

27. Oliveira, M. W.; P. C. O. Trivelin; G. J. Castro Gava e C. P. Penatti. 1999a. Degradaçao da palhada de cana-de-açucar. [On line]. Sci. Agric. 56 (4). Available at www.scielo.br/scielo.php (accessed 8 January 2010). [ Links ]

28. Oliveira, M. W.; P. C. O. Trivelin; G. Kingston; M. H. Pereira Barbosa and A. C. Vitti. 2002. Decomposition and release of nutrients from sugarcane trash in two agricultural environments in Brazil. Proc. Aust. Soc. Sugar Cane Technol. 24: 290-296. [ Links ]

29. Oliveira, M. W.; P. C. O. Trivelin; C. P. Penatti e M. Piccolo. 1999b. Decomposiçao e liberaçao de nutrientes da palhada de cana-de-açucar em campo. Pesq. Agropec. Bras. 34 (12): 2359-2362. [ Links ]

30. Prove, B. G.; V. J. Doogan and P. N. V. Troung. 1995. Nature and magnitude of soil erosion in sugarcane land on the wet tropical coast of northeastern Queensland. Aust. J. Exp. Agric. 35: 641-649. [ Links ]

31. Rípoli, T. C.; W. F. Molina; J. P. Stupiello; M. C. Nogueira y J. B. Saccomano. 1991. Potencial energético de residuos de cosecha de la caña verde. Alcool e Subprodutos 10 (1): 22-28. [ Links ]

32. Robertson, F. A. 2003. Sugarcane trash management: consequences for soil carbon and nitrogen. Final Report to the CRC for Sustainable Sugar Production. CRC for Sustainable Sugar Production, Townsville, Australia. [ Links ]

33. Robertson, F. A. and P. Thorburn. 2007. Decomposition of sugarcane residue in different climatic zones. Aust. J. Soil Res. 45: 1-11. [ Links ]

34. Romero, E. R.; P. A. Digonzelli; L. Alonso; J. Fernández de Ullivarri; G. A. Sanzano; J. Scandaliaris y H. Rojas Quinteros. 2007. La caña verde: un aporte a la sustentabilidad de la producción de caña de azúcar. I: Consideraciones generales. Avance Agroind. 28 (4): 11-15. [ Links ]

35. Romero, E. R.; J. Scandaliaris; P. A. Digonzelli; L. G. Alonso; M. F. Leggio; J. A. Giardina; S. D. Casen; M. J. Tonatto and J. Fernández de Ullivarri. 2009. Effect of variety and cane yield on sugarcane potential trash. Rev. Ind. y Agríc. de Tucumán 86 (1): 9-13. [ Links ]

36. Sánchez, S. R.; G. A. Studdert y H. E. Echeverria. 1996. Descomposición de residuos de cosecha en un argiudol típico. Cien. Suelo 14: 63-68. [ Links ]

37. Sanzano, G. A. y G. S. Fadda. 2009. Características de los suelos para caña de azúcar: recomendaciones de manejo. En: Romero, E. R.; P. A. Digonzelli y J. Scandaliaris (eds.), Manual del cañero, EEAOC, Tucumán, Argentina, pp. 23-34. [ Links ]

38. Sanzano, G. A.; F. A. Sosa; C. F. Hernández; M. Morandini; H. Rojas Quinteros; J. I. Romero y P. A. Digonzelli. 2009. Evaluación de la erosión hídrica en caña de azúcar con y sin cobertura de maloja. Avance Agroind. 30 (3): 16-18. [ Links ]

39. Schomberg, H. H.; J. L. Steiner and P. W. Unger. 1994. Decomposition and nitrogen dynamics of crop residues: residue quality and water effects. Soil Sci. Soc. Am. J. 58: 372-381. [ Links ]

40. Seneviratne, G. 2000. Litter quality and nitrogen release in tropical agriculture: a synthesis. Biol. Fertil. Soils 3: 60-64. [ Links ]

41. Souza, Z. M.; R. Mello Prado; A. C. Paixao e L. G. Cesarin. 2005. Sistemas de colheita e manejo da palhada de cana-de.açucar. Pesq. Agropec. Bras. 40 (3): 271-278. [ Links ]

42. Spain, A. V. and M. J. Hodgen. 1994. Changes in the composition of sugarcane harvest residues during decomposition as a surface mulch. Biol. Fertil. Soils 17: 225-231. [ Links ]

43. Stanford, G.; M. H. Frere and D. H. Shwaninger. 1973. Temperature coefficient of soil nitrogen mineralization. Soil Sci. 115: 321-323. [ Links ]

44. Sttot, D. E.; L. F. Elliot; R. I. Papendick and G. S. Campbell. 1986. Low temperature or low water potential effects on the microbial decomposition of wheat residue. Soil Biol. Biochem.18: 577-582. [ Links ]

45. Thorburn, P. J.; H. L. Horan and J. S. Biggs. 2004. Nitrogen management following crop residue retention in sugarcane production. [On line]. Available at www.regional.org.au/au/asssi/supersoil2004/s9/oral/index.htm. (accessed 8 January 2010). [ Links ]

46. Thorburn, P. J.; E. A. Meier and M. E. Probert. 2005. Modelling nitrogen dynamics in sugarcane systems: Recent advances and applications. Field Crops Res. 92: 337-351. [ Links ]

47. Thorburn, P. J.; M. E. Probert and F. A. Robertson. 2001. Modelling decomposition of sugar cane surface residues with APSIM-Residue. Field Crops Res. 70: 223-232. [ Links ]

48. Trivelin, P. C. O.; R. L. Victoria e J. C. S. Rodrigues. 1995. Aproveitamento por soqueira de cana-de-açucar de final de safra do nitrogenio da aquamonia-15N e ureia-15N aplicado ao solo em complemento a vinhaça. Pesq. Agropec. Bras. 30 (12): 1375-1385. [ Links ]

49. Vallis, I.; W. Parton; B. Keating and A. Wood. 1996. Simulation of the effects of trash and N fertilizer management on soil organic matter levels and yields of sugarcane. Soil Tillage Res. 38: 115-132. [ Links ]

50. Van Antwerpen, R.; J. H. Meyer and P. E. T. Turner. 2001. The effect of cane trash on yield and nutrition from the long-term field trial at Mount Edgecombe. Proc. S. Afr. Sugar Technol. Assoc. 75: 235-241. [ Links ]

51. Vigil, M. F.; D. E. Kissel and S. J. Smith. 1991. Field crop recovery and modeling of nitrogen mineralized from labeled sorghum residues. Soil Sci. Soc. Am. J. 55: 1031-1037. [ Links ]

52. Wood, A. W. 1985. Soil degradation and management under intensive sugarcane cultivation in North Queesland. Soil Use Manage 1: 120-124. [ Links ]

53. Wood, A. W. 1986. Green cane trash management in the Herbert Valley, preliminary results and research priorities. Proc. of Australian Society of Sugar Cane Technologists: 85-94. [ Links ]

54. Wood, A. W. 1991. Management of crop residues following green harvesting of sugarcane in north Queensland. Soil Tillage Res. 20: 69-85. [ Links ]

55. Yaday, D. V.; S. Todi and A. K. Srivastava. 1987. Recycling of nutrients in trash with N for higher cane yield. Biol. Wastes 20: 133-141. [ Links ]