Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista industrial y agrícola de Tucumán

On-line version ISSN 1851-3018

Rev. ind. agric. Tucumán vol.88 no.2 Las Talitas Dec. 2011

ARTÍCULOS ORIGINALES

Assessing a sustainable sugar cane production system in Tucumán , Argentina

Part 2: Soil water and thermal regime, stalk population dynamics and sugarcane production

Patricia A. Digonzelli*, M. Javier Tonatto*, Eduardo R. Romero*, G. Agustín Sanzano**, Juan Fernández de Ullivarri*, Juan A. Giardina* and Jorge Scandaliaris*

** Sección Caña de Azúcar, EEAOC. pdigonzelli@eeaoc.org.ar

** Sección Suelos y Nutrición Vegetal, EEAOC.

Resumen

La necesidad de implementar sistemas productivos sustentables y amigables con las poblaciones vecinas a los campos conduce a la eliminación de la quema como práctica asociada a la cosecha de la caña de azúcar. Este trabajo forma parte de un estudio donde se compararon dos sistemas de producción de caña de azúcar: a) con cobertura de residuos de cosecha ("mulching") y b) sin cobertura de residuos de cosecha (residuo quemado). Se establecieron macroparcelas en un lote comercial implantado con el cultivar LCP 85-384, en Albarracín, Cruz Alta, Tucumán, R. Argentina. El diseño experimental fue de parcelas divididas con tres repeticiones, estando cada parcela formada por cinco surcos de 30 m . Se evaluaron dos ciclos agrícolas: 2006/2007 y 2007/2008. A partir de la cosecha, se determinaron periódicamente la humedad del suelo a 20 cm y 40 cm de profundidad, la temperatura de suelo a 15 cm de profundidad, la infiltración básica y el número de tallos. Al momento de cosecha, se determinaron número y peso de tallos, a partir de los cuales se estimaron las toneladas de caña por surco y por hectárea. La humedad del suelo resultó mayor en el tratamiento con cobertura de residuos para el ciclo 2007/2008, no así para el ciclo 2006/2007, donde no hubo diferencias entre tratamientos. Este comportamiento dependió de la cantidad y distribución de las lluvias. La temperatura del suelo fue mayor en el tratamiento sin cobertura, situación que se mantuvo hasta el cierre del cañaveral. La dinámica de la población de tallos mostró un número de tallos mayor para el tratamiento con cobertura en el pico del macollaje. A cosecha se mantuvo esta tendencia, pero la diferencia solo fue significativa en 2007/2008. La producción de caña por hectárea fue un 12% y un 55% mayor en el tratamiento con cobertura en 2006/2007 y 2007/2008, respectivamente.

Palabras clave: Caña de azúcar; Sustentabilidad; "Mulching".

Abstract

The need to implement sustainable and productive systems compatible with populations leads to the elimination of burning as a practice associated with sugarcane harvesting. This work is part of a study where two sugarcane production systems were compared: a) with trash blanket (mulching) and b) without trash blanket (burnt residue). Macroplots were established in a commercial field planted with LCP 85- 384, in Albarracín (Cruz Alta, Tucumán , Argentina ). A split-plot experimental design with three replicates was used. Each plot consisted of five 30-m furrows. Two crop cycles were considered: 2006/2007 and 2007/2008. From sugar cane harvest onwards, soil water content at 20-cm and 40-cm depth, soil temperature at 15-cm depth, stalk number and basic infiltration rate were periodically determined. Cane yielding (t/ha and t/100-m row) was estimated at harvesting time using stalk number and weight data. There was a higher water content in the treatment under trash blanket management for the 2007/2008 cycle, but no differences were found between treatments in the 2006/2007 cycle. These results depended on rainfall amount and distribution. Soil temperature was higher in the treatment without trash blanket and this situation was registered until canopy closure. Stalk population dynamics showed a higher stalk number during tillering peak in the treatment with trash blanket. At harvesting time this trend was evident, but the difference was significant only in 2007/2008. Sugarcane production per hectare was 12% and 55% higher in the treatment with trash blanket in 2006/2007 and 2007/2008, respectively.

Key words: Sugarcane; Sustainability; Trash blanket.

Introduction

The increasing need to implement sustainable management systems in sugarcane plantations leads to the elimination of burning before or after harvesting. Sugarcane harvesting without burning is known as green cane harvesting. After green cane harvesting a great quantity of residue (leaves and tops) remains in the field: 7 to 30 tons of dry matter depending on the variety and mainly on field productivity level (Furlani Neto et al., 1997; Oliveira et al., 1999a and b; Thorburn et al., 2001; Souza et al., 2005; Robertson and Thorburn, 2007; Núñez and Spaans, 2007; Romero et al., 2009).

One of the alternatives to manage this residue is to preserve it on the soil as mulching (trash blanketing). This management system allows the return of an important quantity of vegetable residues to the soil, favoring nutrient recycling, increasing soil organic matter contents and soil structural stability, reducing both water and wind erosion, diminishing soil water evaporation, increasing infiltration, allowing a better conservation of soil moisture, reducing soil temperature in the top layer of the profile and favoring mesoflora and microflora proliferation (Wood, 1991; Prove et al., 1995; Braunack and Ainslie, 2001; Graham et al., 1999; Mitchell and Larsen, 2000; Graham et al., 2002; Thorburn et al., 2004; Kingston et al., 2005; Souza et al., 2005; Meier et al., 2006; Digonzelli et al., 2007; Núñez and Spaans, 2007; Romero et al., 2007; Sanzano et al., 2009 and Digonzelli et al., 2011). In addition, changes in soil environmental conditions caused by trash blanketing reduce weed infestation, since many species, especially the annual ones, are not capable of growing under these conditions (Velini e Martins, 1998; Martins et al., 1999; Manechini et al., 2005). Moreover, some experiences indicate that sugarcane trash blanket has an alelopathic effect on weed germination (Sampietro et al., 2006; Viator et al., 2006). Therefore, it is possible to reduce cultural labors provided that equipment designed for working on harvest residues on the ground is used (Digonzelli et al., 2007). In Tucumán, approximately 80% of the sugar cane area is harvested with combine harvesters1, many of which have shredder toppers which leave small residue pieces and a uniform blanket, thus facilitating the use of green cane management systems.

Trash blanket management reduces soil water evaporation and improves rain and irrigation infiltration, thus increasing water content in the first centimeters of soil profile (Morandini et al., 2005; Sanzano et al., 2009).

Tucumán has dry spring conditions and frequently, sugarcane water needs during emergence and tillering are not fulfilled. In this aspect, green cane harvesting with trash blanket is a management alternative that can help to achieve a correct seasonal water status in our productive area (Morandini et al., 2005; Sanzano y Fadda, 2009; Digonzelli et al., 2009).

On the other hand, trash blanket reduces soil temperature in the first centimeters of the profile, which can impair sugarcane emergence and initial growth (Morandini et al., 2005; Digonzelli et al., 2009). Nevertheless, due to trash blanket and the consequent decrease in soil temperature, the main planted varieties in Tucumán register a slower emergence, but final sugarcane production is not affected (Tonatto et al., 2009).

This work is part of a study where two sugarcane production systems were evaluated: a) green cane harvesting with trash blanketing and b) green cane harvesting without trash blanketing (residue burnt immediately after harvest).

This study presents results concerning the effect of trash blanket on soil water status and its thermal regime, stalk population dynamics and sugarcane production.

1J. Scandaliaris, Sección Caña de Azúcar, EEAOC; personal communication.

Materials and methods

For this trial, plots were established in a commercial field in Albarracín (department of Cruz Alta), Tucumán, Argentina (26º47'41" LS and 64º59' 10"LW). Albarracín is in the limit of the subhumid-humid Chaco-Pampeana plain, characterized by an annual mean temperature of 19ºC , an annual mean rainfall between 750 mm and 800 mm and a moderate water deficit from August to October, which is a climatic limitation to sugarcane growing.

Soils in the east of the region are typic Argiustoll with silty loam texture over the surface, and are moderately well drained; their pH is 6.6; organic matter content, 2%; exchangable K, 1.7 cmol c kg-1 and CEC, 17 cmol c kg-1 (Sanzano y Fadda, 2009).

The evaluated variety was LCP 85-384, which is planted in 65% of the sugarcane area and is thus the most widely cultivated variety in Tucumán (Cuenya et al., 2009). Evaluations were carried out through two crop cycles: 2006/2007 and 2007/2008 (second and third ratoon, respectively).

In the first cycle, evaluations were made from November 2006 (after plot harvesting) to July 2007, when the new harvest took place (230 days). The second cycle was evaluated from July 2007 to June 2008 (322 days).

The agronomic management of the plots consisted of practices tipically carried out in the area. These included weed control with post-emergence herbicides, nitrogen fertilization (applying urea manually at a rate of 115 kg ha-1) by the end of November 2006 and in mid November 2007, and no irrigation.

A split-plot experimental design with three replicates was used, with plots of five 30-m-long rows. Plots were harvested without burning, using a combine harvester. The sugarcane management systems evaluated were: a) trash blanketing (12.2 and 16.6 tons of dry matter per hectare in 2006/2007 and 2007/2008, respectively) and b) without trash blanketing. In the plots where the second management system was to be evaluated, residue was burnt immediately after harvest.

Every 20 to 30 days from harvesting date (October 2006 and July 2007) onwards, the following parameters were assessed:

a) Soil water content: one sample per plot was taken at 20 cm and 40 cm depth on furrow side. The gravimetric method was used to determine soil water content. Soil bulk density (BD) was determined with the cylinder method (Black and Hartge, 1986) and values were then transformed from gravimetric to volumetric water content.

b) Basic infiltration rate: it was determined using a disc permeameter to zero suction.

c) Soil temperature: it was registered at 15-cm deep after harvest until February, using automatic sensors Ibutton DS1921G-Spectrum Technologies Inc. ( -40°C to + 85°C ).

d) Stalk population: it was evaluated in fixed 10-meter-long areas in three central rows in each plot.

e) Cane yield components: stalk population was evaluated at the end of every cycle and three samples of 15 successive stalks each were taken (45 stalks per plot) to determine their individual weight.

f) Cane yielding (tons of cane/ha): it was estimated with stalk number and weight.

An ANOVA with fixed effects was used for statistical analysis and means comparisons were performed with Tukey test at 5% significance.

Results and discussion

1. Soil water content and temperature

During the 2006/2007 cycle, there were no differences in soil water content between treatments at any of the evaluated depths. This was probably caused by rainfall rates 68% above the normal level for the October-February period.

In the 2007/2008 cycle, soil water content was higher in treatments with trash blanket at 20-cm depth (Figure 1). By contrast, no significant differences were registered between treatments at 40-cm depth, though again the trash blanket treatment tended to lead to higher soil water contents (Figure 2).

Figure 1. Volumetric moisture at 20-cm depth in treatments with and without trash blanket. Albarracín, department of Cruz Alta (Tucumán, Argentina), 2007/2008 cycle.

Figure 2. Volumetric moisture at 40-cm depth in treatments with and without trash blanket. Albarracín, department of Cruz Alta ( Tucumán , Argentina ), 2007/2008 cycle.

Different letters indicate significant differences (p<= 0.05).

Figures 3 and 4 show soil water content changes at 20-cm and 40-cm depth, respectively, during the 2007/2008 cycle. In addition, soil moisture constants are indicated: field capacity (FC), permanent wilting point (PWP) and 40% of available water (AW), which is considered to be the threshold below which sugarcane is under water stress. Volumetric values were obtained with a BD of

Figure 3. Changes in soil moisture at 20-cm depth in treatments with and without trash blanket. Albarracín, department of Cruz Alta (Tucumán, Argentina), 2007/2008 cycle.

Different letters indicate significant differences (p<= 0.05).

Figure 4. Changes in soil moisture at 40-cm depth in treatments with and without trash blanket. Albarracín, department of Cruz Alta ( Tucumán , Argentina ), 2007/2008 cycle.

Different letters indicate significant differences (p<= 0.05).

These figures show that during 2007/2008, the treatment with trash blanket, was never under water stress, while in the treatment without trash blanket water content at 40-cm depth was below 40% of available water between late December and mid-January (for a 19-day period).

Between early October and late November (a 50-day period), water content at 20-cm depth was significantly higher under trash blanketing (Figure 3). This effect was softened at 40-cm depth, probably due to the fact that there was less soil water evaporation at this level (Figure 4). The trash blanket treatment also showed a higher infiltration rate (43 mm/h), as compared to the treatment without trash blanket (29 mm/h).

The differences in soil water contents tended to disappear in December, when plants canopy shaded the soil and canopy closure approached (intercepting approximately 70% of the incident radiation).

The results of this work indicate that although trash blanket affects soil water content, this effect depends on annual rainfall rates and distribution. Similar results were found by Scandaliaris et al. (1999 and 2002) and Morandini et al. (2005) in Tucumán, and by Van Antwerpen et al. (2006) in South Africa .

In Australia , Wood (1986 and 1991) compared three treatments: 1) trash blanketing, 2) incorporation of harvest residues into the soil and 3) burning residue after harvest. This author reported higher water content and less soil moisture variation under trash blanketing. In addition, he indicated that the lowest soil water content occurred when post harvest residues were burnt.

Page et al. (1986) found higher moisture contents in soils under trash blanket management than in unblanketed soils. In coincidence with results in the present work, these authors indicated that differences in moisture content between soils with and without trash blanket were more significant above 30-cm depth, whereas they became less evident between 30-cm and 60-cm depth.

In Brazil , Ball-Coelho et al. (1993) reported higher moisture content and higher proportion of water storage pores in soils with trash blanket compared to those unblanketed. The authors suggested that the greater storage porosity was a consequence of better root development and increased microbial activity, especially that of fungi, in trash-blanketed soils. In Tucumán, Morandini et al. (2005) reported higher moisture contents up to 45-cm depth in soils under trash blanketing, as compared to those where harvest residue was burned.They also indicated that the effect of trash blanket on soil moisture was highly dependent on rainfall amount and sequence.

In Ecuador , Núñez and Spaans (2007) analyzed soil moisture content and daily evapotranspiration in two situations: with trash blanket and removing trash blanket through burning. These authors reported higher moisture content in soils with trash blanket and a reduction between 34% and 39% of daily evapotranspiration rate for this treatment. As a result of these effects, it was possible to reduce irrigation frequency in the trash blanket treatment.

On the other hand, papers by Torres and Villegas (1996) and Chapman et al. (2001) showed that trash blanket diminished soil moisture loss by reducing soil water evaporation, and that this effect continued until crop canopy closure.

Sugarcane in Tucumán is managed without irrigation and due to the monsoon regime, rainfall is concentrated during summer. Spring is dry, so generally rainfall does not meet sugarcane water requirements during emergence and tillering phases. Therefore, the results of this study confirm that in an important part of the sugarcane cropping area in Tucumán, with medium-textured soils and without drainage and high water table problems, trash blanket systems may represent a tool to decrease water deficit in spring (Romero et al., 2000; Sanzano y Fadda, 2009).

Figures 5 and 6 show mean daily temperatures in treatments with and without trash blanket for the two crop cycles.

In both cycles, the treatment without trash blanket tended to have a higher soil temperature during spring and early December until late January (not always with statistical significance). In that period, which coincided with canopy closure, treatments were similar (Figures 5 and 6). This was also reported by Page et al., 1986; Wood, 1991; Chapman et al., 2001; Morandini et al., 2005; Viator et al., 2005 and Morandini et al., 2009.

Figure 5. Soil temperature at 15-cm depth. Albarracín, department of Cruz Alta (Tucumán, Argentina), 2006/2007 cycle.

Figure 6. Soil temperature at 15-cm depth. Albarracín, department of Cruz Alta ( Tucumán , Argentina ), 2007/2008 cycle.

In the 2006/2007 cycle, the treatment without trash blanket presented a daily mean soil temperature that ranged from 27.3ºC to 22.2ºC (mean temperature: 24.7ºC ) bet ween November and February, as compared to a temperature between 26ºC and 22.4ºC (mean temperature: 24.4ºC ) recorded for the treatment under trash blanketing. Hence average difference in soil temperature between treatments was 0.3ºC, and mean daily temperatures did not differ significantly between treatments.

In the 2007/2008 cycle, daily mean soil temperature recorded for the treatment without trash blanket varied from 15.7ºC to 29.3ºC between the end of September and February (mean temperature: 24.1ºC ), whereas the trash blanket treatment presented a temperature ranging between 14.8ºC and 27.9ºC (mean value: 22.5°C ). For this cycle, average soil temperature difference between treatments was 1.6°C.

In a daily analysis, temperature differences between treatments were statistically significant from 23 to 30 October, 3 to 10 November, and 13 to 16 November.

Soil temperature differences between treatments, though not always statistically significant, had a biological significance as they allowed reaching the thermal threshold for earlier or later sprouting, thus explaining the different emergence percentages and rates obtained with each treatment and variety.

Smaller temperature differences between treatments in the 2006/2007 cycle were probably related to abundant rainfall in that cycle between October and February.

Page et al. (1986) reported that soil temperature was 3ºC lower at 15-cm depth in soils under trash blanket treatments. Similarly, Wood (1991) found that soil temperature was 6.2°C lower at 5-cm depth in soils under trash blanketing between October and December, in Australia . Differences faded after December, when crop canopy shaded the ground.

Weir et al. (1998) reported a mean increase of 1.4ºC in soils with little residue cover, as compared with those with a large quantity of residue.

Chapman et al. (2001) registered soil temperature at 15-cm depth and it was 3.8ºC lower in soils under trash blanketing than in soils where residue was burnt after harvest. Irrigation or rainfall reduced temperature diferences between treatments.

In Tucumán, Morandini et al. (2005) recorded a soil temperature increase in treatments without trash blanket, as compared to those with trash blanket. Differences ranged from 0.6ºC to 3.6ºC (mean difference: 1.5ºC ). These authors suggested that temperature differences vanished when canopy closed and that irrigated treatments had smaller temperature differences.

In Louisiana Viator et al. (2005) showed that in winter, trash-blanketed plots had a mean soil temperature 0.8ºC higher than those without residue, while in spring plots with trash blanket had an average soil temperature 3°C lower than plots without residue. It should be remembered that winter temperatures in Louisiana sugarcane area are extremely low and even reach -10ºC , and freezes occurr.

Morandini et al. (2009) reported that from emergence onset to canopy closure, mean soil temperature was 1.8°C lower in trash blanket treatments than in soils without residue. These authors also reported that irrigation and rainfall reduced soil temperature differences between both types of treatment.

2. Stalk population dynamics

Figures 7 and 8 show stalk population dynamics for treatments with and without trash blanket during the two crop cycles studied. The curves represent typical sugarcane stalk population dynamics, namely an increase in stalk number (in emergence and tillering phases) till reaching its peak, and then a drop until reaching final stalk population (Romero, 2000).

Figure 7. Stalk population dynamics. Albarracín, department of Cruz Alta ( Tucumán , Argentina ), 2006/2007 cycle.

Different letters indicate significant differences (p<= 0.05).

Figure 8. Stalk population dynamics. Albarracín, department of Cruz Alta ( Tucumán , Argentina ), 2007/2008 cycle.

Different letters indicate significant differences (p<= 0.05).

*Different letters indicate significant differences (p<= 0.08).

In contrast with other reports (Chapman et al., 2001; Kingston , 2002; Morandini et al., 2005), no significant differences in emergence between treatments were registered in the 2006/2007 cycle. This was probably due to the fact that mean soil temperature at harvesting time (late October) was always above 20ºC (Figure 5). As a consequence of this, the effect of trash blanket treatments on emergence delay was not observed. In this cycle, maximum stalk number/m was reached in December and it was significantly higher under the trash blanket treatment (43.5 stalks/m) than in the treatment without trash blanket (33 stalks/m). No differences were found between treatments on other assessment dates.

After an early harvest (July 2007) in the 2007/2008 cycle, the treatment without trash blanket showed a higher stalk number/m at emergence onset (late August- September). From that date until December, no differences were recorded between treatments. In December, maximum stalk number/m was reached: the trash blanket treatment reached 35.7 stalks/m, whereas the treatment without mulching presented 23.7 stalks/m, being these values significantly different at the 8% level.

At harvesting time, stalk number/m in the trash blanket treatment (22 stalks/m) was higher than that in the treatment without residue cover (16 stalks/m).

Stalk mortality rate was similar in both treatments and in both cycles: 36% to 47% in 2006/2007, and 33% to 37% in 2007/2008.

Page et al. (1986) reported that after eight weeks, sugarcane harvested in August showed a 45% lower stalk population in plots with trash blanket. However, twelve weeks after harvest, stalk population was 16% larger under the trash blanket treatment. This showed the advantages of trash blanket management during warm seasons. No differences in stalk population were observed during October and November harvests at any time.

Ball-Coelho et al. (1993) reported similar tillering levels for treatments with and without trash blanket.

In Brazil , Alvarez e de Camargo e Castro (1999) found no significant differences in stalk number/m in treatments with and without trash blanket. However, the trash blanket treatment tended to present a greater stalk number/m at maximum tillering stage.

Torres and Villegas (1996) and Kingston (2002) found a smaller stalk population in early growth stages under trash blanket management. Nonetheless after the sixth month, stalk number/ha was similar in both treatments.

Chapman et al. (2001) noted a slower emergence in fields under trash blanket management when they were harvested in both July and November. Stalk population reached its maximum value in January, and no differences between treatments (with and without trash blanket) were observed.

In Louisiana , Richard (2001) reported an emergence decrease of 29% under trash blanket management. Nevertheless after six months, stalk population differences between treatments were reduced to 5%.

Morandini et al. (2005) reported a higher stalk number/m at emergence phase and beginning of tillering in treatments without trash blanket. Maximum stalk population was slightly higher in treatments with trash blanket, with no statistical significance. Stalk number/m at harvest time was similar in both treatments.

Núñez and Spaans (2007) reported fewer stalks/m in trash blanket treatments throughout the crop cycle, even though this difference was not statistically significant at any assessment date.

3- Yield components

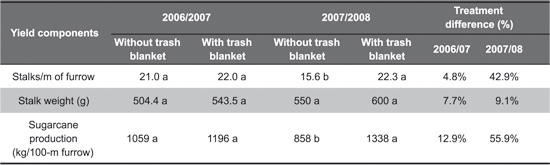

Table 1 shows stalk population per row meter, individual stalk weight and sugarcane production per 100- m rows in treatments with and without trash blanket, during the two crop cycles.

Table 1. Stalk number per row meter, individual stalk weight and sugarcane yield per 100-m row for treatments with and without trash blanket. Albarracín, department of Cruz Alta (Tucumán, Argentina). 2006/2007 and 2007/2008 cycles.

In the 2006/2007, cycle there were no differences in stalk number and weight and sugarcane production per 100-m row between treatments. However, a slight difference favoring trash blanket management was observed.

In the 2007/2008 cycle, stalk population and sugarcane production per 100-m row were significantly higher under the trash blanket treatment (differences of 43% and 56%, respectively). No significant differences between treatments were found with respect to individual stalk weight. However, the trash blanket treatment showed 9% higher values than the unblanketed treatment. Highest sugarcane production per 100-m row in the trash blanket treatment resulted mainly from a higher stalk population and, to a lesser extent, to a higher stalk weight recorded for this treatment.

In Colombia , Torres and Villegas (1996) found no differences in stalk number/ha and stalk height at harvest between the treatments with chopped harvest residues and sugarcane burning before harvest.

Alvarez e de Camargo e Castro (1999), when comparing burnt versus unburnt harvested sugarcane, did not detect any significant differences in stalk number at harvest. A larger stalk diameter was registered under unburnt residue management, whereas in the second year of evaluation, burnt cane stalks were taller.

In Louisiana , Richard (2001) found no differences in stalk weight between treatments, but stalk number/ha at harvest was lower for the trash blanket treatment.

Chapman et al. (2001) found a similar stalk number at harvest in treatments with and without trash blanket. Stalk weight was significantly higher under the trash blanket treatment.

Kingston (2002) found no differences in stalk number at harvest between treatments with and without residues. On the other hand, Núñez and Spaans (2007) found a slightly smaller stalk population under the trash blanket treatment as compared to burnt residue management, but this difference was not statistically significant. Nor did they find any significant differences in height or stalk diameter.

With the results obtained in this study, sugarcane production per hectare for both treatments and considered cycles was estimated (Figure 9).

In the 2006/2007 cycle, there were no significant differences between treatments as regards sugarcane production per hectare. However, yield in the trash blanket treatment was 12% higher than in the treatment without trash blanket. This parameter became significantly higher in the treatment with mulching in the 2007/2008 cycle, with a 55% increase.

No significant differences were found when sugarcane production levels for each treatment (with or without trash blanket) were compared during the two studied cycles (Figure 9).

Figure 9. Sugarcane production per hectare in treatments with and without trash blanket management. Albarracín, department of Cruz Alta ( Tucumán , Argentina ). 2006/2007 and 2007/2008 cycles.

Different letters indicate significant differences (p<= 0.05).

Wood (1991) indicated that in well-drained soils in Australia , trash blanket management represented a mean yield increase of 10 t/ha.

Ball-Coelho et al. (1993) reported a 46% increase in sugarcane production per hectare when harvest residues were left in the field.

Vallis et al. (1996) analyzed the effects of trash blanketing on various soil parameters and sugarcane production in Australia through simulation models. These authors found a major sugarcane production in trash blanket treatments, whether fertilized with N or not. For the treatment with 100 kg N/ha, the increase due to trash blanket management reached 20 t/ha.

Chapman et al. (2001) found a significant increase in sugarcane production under trash blanket management. These authors reported a mean increase of 11.5 t/ha in late harvest (November) and 16 t/ha in early harvest (June and July).

Scandaliaris et al. (2002) compared treatments with and without trash blanket and different N doses ( 0 kg N/ha to 150 kg N/ha) in Tucumán. These authors registered a higher sugarcane production under trash blanket management, regardless of the N rates used. Production increase ranged between 10% and 33%.

Studying sugarcane production under no irrigation in Tucumán, Morandini et al. (2005) found no differences between treatments with and without trash blanket. These authors suggested that there were probably no productivity gains with trash blanketing during the considered seasons, on account of a very severe and prolonged drought spell that lasted from August to November, preventing the expression of positive effects on soil moisture. In Brazil , Souza et al. (2005) found no differences in sugarcane production/ha between plots with and without trash blanket.

The sugarcane production increase under trash blanket management reported in this paper, especially in the 2007/2008 cycle, was possibly associated with higher soil moisture content and less weed competition, as compared to the unblanketed treatment. In the latter, soil moisture was significantly lower and post-emergence herbicide control, especially in rows, was not totally effective. Similar results were reported by Page et al. (1986), Wood (1991), Ball-Coelho et al. (1993), Vallis et al. (1996), Chapman et al. (2001), Kingston (2002), Scandaliaris et al. (2002) and Van Antwerpen et al. (2006).

Conclusions

Keeping a trash blanket on the soil surface increased moisture conservation, especially in topsoil profile. This effect was dependent on rainfall amount and distribution and lasted until canopy closure. Moreover, water infiltration into the soil was greater under trash blanket management.

Another effect of the trash blanket treatment was that soil temperature decreased, and thus sugarcane emergence and early growth were delayed in early harvest (July). Temperature differences between treatments with and without trash blanket were observed until canopy closure, but they were attenuated by rainfall occurrence.

Under our trial conditions, with medium-textured soils without drainage problems or a high water table, trash blanket management rose sugarcane production per hectare. This was especially evident in cycles where both distribution and amount of rainfall were normal for our province, with a water deficit during spring coinciding with emergence and tillering phases.

While there were no differences between treatments concerning stalk weight, a larger stalk population was recorded for the trash blanket treatment at harvest time, which led to an increase in sugarcane production per hectare.

Acknowledgments

We are grateful to Mariano Abregú, Agr. Eng. (J. J. Budeguer Company), for cooperating with our assay.

Cited references

1. Alvarez, I. A. e P. R. de Camargo e Castro. 1999. Crescimento da parte aerea de cana crua e queimada. Sci. Agric. 56 (4): 1069-1079. [ Links ]

2. Ball-Coelho, B.; H. Tiessen; W. R. Stewart; I. H. Salcedo and E. V. S. B. Sampaio. 1993. Residue management effects on sugarcane yield and soil properties in northwestern Brazil . Agron. J. 85: 1004-1008. [ Links ]

3. Black, G. R. and K. H. Hartge. 1986. Bulk density. In: Klute, A. (ed.), Methods of soil analysis. Part I: Physical and mineralogical methods, ASA-SSSA Inc., Madison , WI , USA , pp. 363-376. [ Links ]

4. Braunack, M. and H. Ainslie. 2001. Trash blankets and soil physical properties: Mackay experience. Proc. Aust. Soc. Sugar Cane Technol. 23: 154-160. [ Links ]

5. Cuenya, M. I.; S. Ostengo; E. R. Chavanne; M. A. Espinoza; D. D. Costilla y M. A. Ahmed. 2009. Relevamiento de la distribución de variedades comerciales y de la aplicación de otras tecnologías en el área de cultivo de caña de azúcar de la provincia de Tucumán: campaña 2007/2008. Gac. Agroind. EEAOC (72). [ Links ]

6. Chapman, L. S.; P. L. Larsen and J. Jackson. 2001. Trash conservation increases cane yield in the Mackay District. Proc. Aust. Soc. Sugar Cane Techonol. 23: 176-184. [ Links ]

7. Digonzelli, P. A.; J. Fernández de Ullivarri; E. Romero; J. Giardina; L. Alonso; S. Casen; J. Tonatto; M. Leggio Neme and J. Scandaliaris. 2009. Assessment of two sugarcane management systems: with or without post-green-cane-harvest residue retention. In: Proc. ISSCT Agronomy Workshop, 8, Uberlandia , Brasil, pp. 27-28. [ Links ]

8. Digonzelli, P. A.; E. R. Romero; L. Alonso; J. Fernández de Ullivarri; H. Rojas Quinteros and S. Fajre. 2011. Assessing a sustainable sugarcane production system in Tucumán , Argentina . Part 1: Dynamics of sugarcane harvest residue (trash) decomposition. Rev. Ind. y Agríc. de Tucumán 88 (1): 1-12. [ Links ]

9. Digonzelli, P. A.; J. Scandaliaris; M. J. Tonatto; J. A. Giardina; S. D. Casen; M. F. Leggio Neme y E. R. Romero. 2007. La caña verde: un aporte a la sustentabilidad de la producción de caña de azúcar. II: Alternativas y equipos para el manejo del cañaveral sin quema. Avance Agroind. 28 (4): 16-20. [ Links ]

10. Furlani Neto, V. L.; T. C. Ripoli e N. A. Villa Nova. 1997. Biomassa de cana-de-açucar: energia contida no palhiço remanescente de colheita mecânica. STAB- Açucar, Alcool e Subproductos 15 (4): 24-27. [ Links ]

11. Graham, M. H.; R. J. Haynes and J. H. Meyer. 1999. Green cane harvesting promotes accumulation of soil organic matter and an improvement in soil health. Proc. S. Afr. Sug. Technol. Ass. 73: 53-57. [ Links ]

12. Graham, M. H.; R. J. Haynes and J. H. Meyer. 2002. Changes in soil chemistry and aggregate stability induced by fertilizer applications, burning and trash retention on a long-term sugarcane experiment in South Africa . Eu. J. Soil Sci. 53: 589-598. [ Links ]

13. Kingston , G. 2002. Experience with the green-cane trash-blanket production system in Australia-industry experience and recent research. In: Memoria Técnica del Congreso de ATACA, 14, Guatemala , pp. 175-185. [ Links ]

14. Kingston, G.; J. L. Donzelli; J. H. Meyer; E. P. Richard; S. Seeruttun; J. Torres and R. Van Antwerpen. 2005. Impact of green cane harvest and production system on the agronomy of sugarcane. In: Proc. ISSCT Congress, 25, Guatemala, Guatemala, pp. 521-533. [ Links ]

15. Manechini, C.; A. Ricci and J. L. Donzelli. 2005. Benefits and problems of trash left in the field. In: Hassuani, S. J.; M. R Lima Verde Leal and I. De Carvalho Macedo (eds.), Biomass power generation. Sugar cane bagasse and trash. PNUD, CTC, Piracicaba, Brasil, pp. 26-34. [ Links ]

16. Martins, D.; E. D. Velini; C. C. Martins e L. S. Souza. 1999. Emergencia em campo de dicotiledoneas infestantes em solo coberto com palha de cana-de-açucar. Planta Daninha 17 (1): 151-161. [ Links ]

17. Meier, E.; P. J. Thorburn; K. Wegener and K. Basford. 2006. The availability of nitrogen from sugarcane trash on contrasting soils in the wet tropics of North Queensland . Nutr. Cycl. Agroecosyst. 75: 101-114. [ Links ]

18. Mitchell, R. D. J. and P. Larsen. 2000. A simple method for estimating the return of nutrients in sugarcane trash. Proc. Aust. Soc. Sugar Cane Technol. 22: 212-216. [ Links ]

19. Morandini, M.; R. Figueroa; F. Pérez Zamora and J. Scandaliaris. 2005. The effects of green cane trash blanket on soil temperature, soil moisture and sugarcane growth. In: Proc. ISSCT Congress, 25, Guatemala, Guatemala, pp. 231-236. [ Links ]

20. Morandini, M.; C. Hernández; H. Rojas Quinteros y G. A. Sanzano. 2009. Efecto de la conservación de residuos de cosecha de la caña de azúcar en la temperatura de un suelo Argiudol típico de la Llanura Chacopampeana subhúmeda-húmeda (Tucumán-Argentina). Rev. Ind. y Agríc. de Tucumán 86 (1): 15-23. [ Links ]

21. Núñez, O. and E. Spaans. 2007.Evaluation of green-cane harvesting and crop management with trash-blanket. In: Proc. ISSCT Congress, 26, Durban , Sudáfrica, pp. 131-142. [ Links ]

22. Oliveira, M. W.; P. C. O. Trivelin; G. J. Castro Gava e C. P. Penatti. 1999a. Degradaçao da palhada de cana-de-açucar. Sci. Agric. 56 (4). [On line]. Available at www.scielo.br/scielo (accessed 8 January 2010). [ Links ]

23. Oliveira, M. W.; P. C. O. Trivelin; C. P. Penatti e M. Piccolo. 1999b. Decomposiçao e liberaçao de nutrientes da palhada de cana-de-açucar em campo. Pesq. Agropec. Bras. 34 (12): 2359-2362. [ Links ]

24. Page, R. E.; T. J. Glanville and P. N. Truong. 1986. The significance of trash retention trials in the Isis and Maryborough mill areas. Proc. Aust. Soc. Sugar Cane Technol. 8: 95-102. [ Links ]

25. Prove, B. G.; V. J. Doogan and P. N. V. Troung. 1995. Nature and magnitude of soil erosion in sugarcane land on the wet tropical coast of northeastern Queesland. Aust. J. Exp. Agric. 35: 641-649. [ Links ]

26. Richard, E. P. 2001. Management of chopper harvester-generated green cane trash blankets: a new concern for Louisiana . In: Proc. ISSCT Congress, 24, Brisbane , Australia , pp. 52-60. [ Links ]

27. Robertson, F. A. and P. Thorburn. 2007. Decomposition of sugarcane residue in different climatic zones. Aust. J. Soil Res. 45: 1-11. [ Links ]

28. Romero, E. R. 2000. Dinámica de la brotación y del crecimiento inicial de la caña de azúcar. Efectos de factores intrínsecos, ambientales y de manejo. Tesis doctoral inédita. FAZ-UNT, Tucumán, R. Argentina. [ Links ]

29. Romero, E. R.; P. A. Digonzelli; L. G. Alonso; J. Fernández de Ullivarri; G. A. Sanzano; J. Scandaliaris y H. Rojas Quinteros. 2007. La caña verde: un aporte a la sustentabilidad de la producción de caña de azúcar. I: Consideraciones generales. Avance Agroind. 28 (4): 11-15. [ Links ]

30. Romero, E. R.; J. Scandaliaris; P. A. Digonzelli; L. G. Alonso; M. F. Leggio; J. A. Giardina; S. D. Casen; M. J. Tonatto y J. Fernández de Ullivarri. 2009. Effect of variety and cane yield on sugarcane potential trash. Rev. Ind. y Agríc. de Tucumán 86 (1): 9-13. [ Links ]

31. Romero, E. R.; J. Scandaliaris; M. Rufino y M. Morandini. 2000. Importancia del manejo hídrico en la mejora de la capacidad productiva de la caña de azúcar en Tucumán. In: Mem. Seminarios Inter-Americanos de Caña de Azúcar, Miami, EE. UU., pp.16-18. [ Links ]

32. Sampietro, D.; M. Vattuone and M. Isla. 2006. Plant growth inhibitors isolated from sugarcane (Saccharum officinarum) straw. J. Plant Physiol. 163: 837-846. [ Links ]

33. Sanzano, G. A. y G. S. Fadda. 2009.Características de los suelos para caña de azúcar: recomendaciones de manejo. In: Romero, E. R.; P. A. Digonzelli y J. Scandaliaris (eds.), Manual del Cañero, EEAOC, Tucumán, R. Argentina, pp. 23-34. [ Links ]

34. Sanzano, G. A.; F. A. Sosa; C. F. Hernández; M. Morandini; H. Rojas Quinteros; J. I. Romero y P. A. Digonzelli. 2009. Evaluación de la erosión hídrica en caña de azúcar con y sin cobertura de maloja. Avance Agroind. 30 (3): 16-18. [ Links ]

35. Scandaliaris, J.; M. Morandini; F. Pérez Zamora y N. Dantur. 1999. El manejo con caña verde y cultivo mínimo en la producción de caña de azúcar en Tucumán. Avance Agroind. 12 (79): 8-12. [ Links ]

36. Scandaliaris, J.; F. Pérez Zamora; M. Rufino; E. R. Romero y M. Morandini. 2002. La cosecha en verde como estrategia para disminuir el impacto ambiental de la caña de azúcar. Avance Agroind. 23 (1): 14-17. [ Links ]

37. Souza, Z. M.; R. Mello Prado; A. C. Paixao e L. G. Cesarin. 2005. Sistemas de colheita e manejo da palhada de cana-de-açucar. Pesq. Agropec. Bra. 40 (3): 271-278. [ Links ]

38. Thorburn, P. J.; H. L. Horan and J. S. Biggs. 2004. Nitrogen management following crop residue retention in sugarcane production. [On line]. Available at www.regional.org.au/au/asssi/supersoil2004/s9/oral/ index.htm (accessed 8 January 2010). [ Links ]

39. Thorburn, P. J.; M. E. Probert and F. A. Robertson. 2001. Modelling decomposition of sugar cane surface residues with APSIM-residue. Field Crops Res. 70: 223-232. [ Links ]

40. Tonatto, M. J.; J. F. de Ullivarri; E. Romero; P. Digonzelli; F. Pérez; J. Scandaliaris; L. Alonso; J. Giardina; S. Casen and M. Leggio Neme. 2009. Effect of post harvest trash management in sugarcane shoot emergence dynamics for Tucumán-Argentina. In: ISSCT Agronomy Workshop, 8, Uberlandia , Brasil, 2009, pp. 68-69. [ Links ]

41. Torres, J. and F. Villegas. 1996. Green cane management under heavy trash conditions. In: Proc. ISSCT Congress, 22, Cartagena , Colombia , 1996, pp. 142-148. [ Links ]

42. Vallis, I. ; W. Parton; B. Keating and A. Wood. 1996. Simulation of the effects of trash and N fertilizer management on soil organic matter levels and yields of sugarcane. Soil Tillage Res. 38: 115-132. [ Links ]

43. Van Antwerpen, R.; J. H. Meyer and G. D. Thompson. 2006. The impact of trashing on yield response in the South African sugar industry: a summary of results from several BT trials. Proc. S. Afr. Sug. Technol. Ass. 80: 130-135. [ Links ]

44. Velini, E. D. e D. Martins. 1998. Efeito da palha de cana-de-açucar sobre a germinaçao das principais especies de plantas daninhas desta cultura. Informe Técnico FCA/UNESP. San Pablo, Brasil. [ Links ]

45. Viator, R. P.; R. M. Johnson; C. C. Grimm and E. P. Richard. 2006. Allelopathic, autotoxic and hormetic effects of post-harvest sugarcane residue. Agron. J. 98: 1526-1531. [ Links ]

46. Viator, R. P.; R. M. Johnson and E. P. Richard. 2005. Challenges of post harvest residue management in the Louisiana sugarcane industry. In: Proc. ISSCT Congress, 25, Guatemala , Guatemala , pp. 238-245. [ Links ]

47. Weir, K. L.; D. E. Rolston and P. J. Thorburn. 1998. The potential for N losses via desnitrification beneath a green cane trash blanket. Proc. Aust. Soc. Sugar Cane Technol. 20: 169-174. [ Links ]

48. Wood, A. W. 1986. Green cane trash management in the Herbert Valley , preliminary results and research priorities. Proc. Aust. Soc. Sugar Cane Technol. 8: 85-94. [ Links ]

49. Wood, A. W. 1991. Management of crop residues following green harvesting of sugarcane in north Queensland . Soil and Tillage Res. 20: 69-85. [ Links ]