Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Revista industrial y agrícola de Tucumán

On-line version ISSN 1851-3018

Rev. ind. agric. Tucumán vol.93 no.2 Las Talitas Dec. 2016

TRABAJO YA PUBLICADO

Assessment of bioctivators in sugar cane, Tucumán, Argentina

Luis Gonzalo Alonso*, Eduardo R. Romero*, Pablo E. Fernández González*, María Fernanda Leggio*, Sofía Fajre* y Jorge Scandaliaris*

*Sección Caña de Azúcar, EEAOC. lgalonso@eeaoc.org.ar

Abstract

We evaluated the use of a foliar bioactivator at the beginning of the rainy season, as a strategy to accelerate sugarcane recovery after it had undergone the negative effects of water deficits at the onset of the crop cycle.

Three trials were carried out in commercial fields planted with variety LCP 85-384 in the first and second ratoon crops, located in areas with different water stress levels and with soils with different organic matter content. Four treatments were evaluated: 1) a control; 2) bioactivator 2 L/ha (B); 3) conventional fertilisation at a rate of 115 kg of N/ha- (CF) and 4) CF + B. At harvest, stalk population and stalk weight were measured and yield was estimated for each treatment. These assessments were complemented with sugarcane factory yield analyses. All the data were analysed with an ANOVA and a Fisher’s test (at 5 and 10% levels of statistical significance). All treatments had significant differences compared to the control regarding stalk population, but the greatest stalk population was obtained with the CF + B treatment (16% > control). All treatments had significantly greater stalk weight (P< 0.10) than the control, but stalk weights did not differ among fertiliser or bioactivator treatments. Weight increases measured in treatments with bio-activators (B and CF + B) amounted to 12%. All treatments had significantly greater cane yield when compared to the control treatment, with the greatest increases attained with the CF + B treatment (29.2% > control). The use of bio-activators influenced yield components in two different ways: when the sugarcane crop was fertilised with N, the bio-activator significantly increased stalk population, whereas in the case of crops without fertilisation, the effect was evident in both stalk population and weight.

Key words: bioactivator, water stress.

Resumen

Evaluación de bioactivadores en caña de azúcar, Tucumán, Argentina

Se evaluó el empleo de bioactivadores foliares en el inicio del período de lluvias en Tucumán, R. Argentina, a fin de facilitar la recuperación del cultivo ante las deficiencias hídricas que sufre el cañaveral en la fases iniciales del ciclo. Se realizaron 3 ensayos en lotes comerciales de caña soca, variedad LCP 85-384, en áreas con diferencias en el régimen pluviométrico y en el contenido de materia orgánica. Se evaluaron 4 tratamientos:

Control; Bioactivador 2 l/ha (B); Urea dosis convencional de 115 kg N/ha (CF); CF + B. En cosecha, se determinó la población de tallos y su peso unitario, y con estos datos se estimó el rendimiento cultural. Además se evaluó la calidad fabril. La información fue analizada con un ANOVA y el test de Fisher (al 5% y 10% de significación). Todos los tratamientos manifestaron diferencias significativas con el testigo al analizar la población de tallos, registrando las mayores diferencias el tratamiento CF + B (16%). En el peso por tallo, todos los tratamientos mostraron diferencias significativas respecto del testigo, pero sin diferencias entre ellos. Los incrementos alcanzados por los tratamientos con bioactivadores (B y CF+B) resultaron de un 12%. En el rendimiento cultural todos los tratamientos manifestaron diferencias significativas respecto del testigo, registrando los mayores incrementos el tratamiento CF + B (29,2%). El bioactivador influyó sobre los componentes del rendimiento de 2 maneras: cuando el cañaveral fue fertilizado con N, el efecto se manifestó en la población de tallos, mientras que en los cañaverales sin fertilizar, el efecto se presentó también en el peso por tallo.

Palabras clave: bioactivadores, estrés hídrico.

![]()

INTRDUCTION

In Tucumán, the beginning of the sugarcane growing season coincides with a period of low rainfall. As a result, and on account of the fact that 80% of plantations are not irrigated, the crop undergoes significant water stress at this stage. Under these conditions, it is of great importance to accomplish a rapid recovery of sugarcane crop in order to ensure high yields. Hence, the use of metabolic bio-activators in sugarcane crops constitutes a tool of great agricultural interest, since they allow the crop to recover rapidly, thus ensuring that plantations will have higher yields.

There is limited information about the use of bio-activators in sugarcane. Garcia et al. (2001) observed that, when they applied a biostimulator named Agrispon on sugarcane crops, they observed positive effects on stalk population, sugar content, increases in sugarcane weight/stalk, length, juice purity, and Pol % in cane.

The objective of this study was to evaluate the performance of a bioactivator made from seaweed extracts, applied at the beginning of the rainy season. This bioactivator was a liquid organic product, which contained amino-acids, hormones, polysaccharides, macronutrients (NPK 5-5-4) and traces of micronutrients (Mg, B, Fe and Zn) in its composition. (PSW SA, 2012).

MATERIALS AND METHODS

For this study, three trials were conducted in commercial plots planted with cultivar LCP 85-384 in the first and second ratoon crops. These plots were located in areas where different water stress levels had been found, and where soil presented different organic matter content levels. Two of these plots had soils with 1.1% and 1.7% organic matter content and were located in areas where average annual rainfall averaged 930 mm. By contrast, the remaining site had soils with high organic matter content (4.2%) and was located in an area with a higher annual rainfall mean (1450 mm).

The experimental design was a randomised block design, where plots had five 100-metre- long rows (a total area of 800 m2).

The following treatments were evaluated:

1. Control

2. Bioactivator 2 L/ha (B).

3. Urea conventional dose = 115 kg of N/ha - (CF)

4. Urea conventional dose + bioactivator 2 L/ha (CF + B)

The application of the bio-activator was performed with a carbon dioxide backpack with a volume of 75 L/ha, after fertilisation with nitrogen and when the crop had 6 to 8 expanded leaves.

At harvest, stalk population was evaluated in 10 m of row, as well as the weight of individual millable stems. With these data, yield for each treatment in the plots was estimated. Also, in the laboratory of the EEAOC Chemistry Department, factory quality of cane juice obtained with the different treatments was analysed.

RESULTS

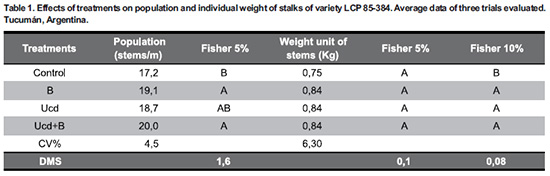

The CF + B treatment led to a higher average sugarcane stalk population, with 2.8 stalks/m of row increase compared with the control, and 1.3 stalks/m of row increase with respect to CF. The B treatment showed an average increase in the number of stalks of 1.8 stems/m of row compared with the control. In all cases except CF, differences with the control were significant (Table 1).

Regarding stalk weight, treatment B showed an average 0.088 kg increase in comparison with the control, while treatment CF + B had no stalk weight increase with the addition of bioactivator with respect to CF. (Table 1).

When analysing cane yield, all treatments were significantly different from the control. The highest yields were observed in plots where bioactivator was applied as a urea supplement (CF + B), with an increase of 23.7 t/ha compared to control, and 7.7 t/ha more than CF treatment (Figure 1). Treatment B had 19.1 t/h over the control and 3.1 t/ha more than CF (Figure 1). However, it should be noted that treatments B, CF and CF + B did not differ significantly from each other. This indicates that the addition of the bioactivator, when applied without nitrogen fertiliser, can lead to yields similar to those generated by traditional fertilisation.

Although this paper does not show the data for each trial evaluated, it was observed that bioactivator treatments showed a tendency to generate greater production increases in areas with low organic matter content and low rainfall.

When analysing juice factory quality, no significant differences were observed among treatments (Table 2).

CONCLUSIONS

The use of the bioactivator resulted in increases in sugarcane production, as stalks established better before the beginning of the harvest season, in both plots with nitrogen fertilisation and without. When sugarcane fields were not fertilised with nitrogen, there was an increase in stalk weight with the addition of a bioactivator.

In this study, the use of bioactivators without additional N fertilisation led to similar sugarcane yields to traditional fertilisation. The use of the bioactivator did not affect the quality of sugarcane juice.

1. García, I., Llerena, E., Díaz, J.C. et al. (2001). Uso de bioestimulante natural en el cultivo de la caña de azúcar. EPICA. Villa Clara, Cuba. Centro azúcar 2/2001.http://www.biblioteca.idict.villaclara.cu/ biblioteca/artículos/ciencia/art91

2. Peruvian Seaweed. Accessed 17 April 2012. www.pswsa.com/nuevosite/biomestimulantes.html.

.