Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Revista de Ciencia y Tecnología

versión On-line ISSN 1851-7587

Rev. cienc. tecnol. no.34 Posadas dic. 2020

Caracterización de las propiedades físicas y modales de los raquis de racimos de mbocayá para recolección mecanizada

Characterization of physical and modal properties of the rachis of macaw palm bunches aiming mechanized harvesting

Zenil Ricardo Cunha Rodrigues de Oliveira1,*, FábioLúcio Santos2, DomingosSarvioMagalhães Valente1, Francisco de Assis de Carvalho Pinto1, MateusResende Rodrigues2

1- Universidade Federal de Viçosa. Brasil.

2- Universidade Federal de Lavras. Brasil.

* E-mail: zenilricardo@gmail.com

Recibido:26/05/2020; Aprobado:20/10/2020

Resumen

La mbocayá (Acrocomiaaculeata) es una alternativa para la producción de biodiésel debido a las características de la planta como la gran adaptabilidad a los diferentes climas y la alta producción de aceite. Sin embargo, su explotación sigue siendo un obstáculo. Dado que el desarrollo de máquinas eficientes para la cosecha y poscosecha de la mbocayá requiere el estudio del comportamiento dinámico de la planta. El método de elementos finitos se puede utilizar en el diseño de máquinas para estudiar el comportamiento dinámico de la planta. Como parámetros de entrada para usar el método de elementos finitos, se les debe informar el sistema geométrico, físico y mecánico en estudio. El objetivo de este estudio fue determinar y evaluar las propiedades geométricas y físicas de los raquis de la mbocayá, además de investigar la transmisibilidad y el barrido de frecuencia mediante vibraciones mecánicas, en diferentes etapas de maduración. Se concluyó que las propiedades físicas y geométricas eran fundamentales para la construcción del modelo y la comprensión del comportamiento dinámico del raquis de la mbocayá. En la evolución de la etapa de maduración de inmaduro a maduro, la primera frecuencia natural cambia en magnitud de 22.66 a 15.90Hz.

Palabras claves:Acrocomiaaculeate; Transmisibilidad; Frecuencias naturales; Vibración mecánica; Barrido de frecuencia.

The Mbocaya palm (Acrocomiaaculeata) is an alternative for the production of biodiesel due to the characteristics of the plant such as the great adaptability to different climates and high production of oil. However, its exploitation remains an obstacle. Since the development of efficient machines for harvesting and post-harvesting of the macaw palm requires the study of the dynamic behavior of the plant, the finite element method can be used in machine design to study the dynamic behavior of the plant. As input parameters for using the finite element method, they should be informed about the geometrical, physical and mechanical system under study. The aim of this study was to determine and evaluate the geometric and physical properties of the rachis of Mbocaya palm, in addition to investigating the transmissibility and frequency sweep by means of mechanical vibrations, at different stages of maturation. It was concluded that the physical and geometric properties were fundamental for the construction of the model and understanding of the dynamic behavior of Mbocaya palm rachis. In the evolution of the maturation stage from immature to mature, the first natural frequency changes in magnitude from 22.66 to 15.90Hz.

Keywords:Acrocomia aculeate;Transmissibility; Natural frequencies;Mechanical vibration; Frequency sweeping.

Introduction

The macaw palm (Acrocomiaaculeata) is a native palm of tropical America, naturally occurring from Central America to extreme south of the American continent (Motoike et al., 2013). In Brazil, it is considered one of the most dispersed palm trees, tolerant to drought and low temperatures; this palm is found along in practically all regions of the country, growing in large populations in degraded or intact areas and is well-adapted to different ecosystems [2], [3].

Worldwide demand for renewable energy sources has been lead the agro-industrial sectors focus on oil crops. Macaw palm can be considered a solution to be introduced as alternative option among the classical oleaginous plants (i.e., soy, peanuts, maize, sunflower, etc.) due to high productivity and quality of its oil, including for the production of biofuels and pharmaceutical products [4], [5].

Commercial plantation, following suitable agronomic care, can yield 16,000-25,000 kg of fruit per hectare and produce up to 6200 kg ha-1 of oil[6]. However, in spite of the potential of macaw palm, its exploitation is based on extractivism, resulting in low productivity and poor quality of the generated products [3], [7]. Nowadays, the harvest is not mechanized, besides being made in a precarious way with scythes adapted to bamboo rods for the cutting the bunch of macaw palm. Due to the large number of spines in the stem and the great height of the plant, the harvest becomes a very expensive operation, causing a great amount of work accidents[1].

Considering that some crops such as coffee [8],olives[9]andtomato[10] employ mechanical harvesting based on mechanical vibrations with expressive results for fruit detachment, this principle can be used for mechanized harvesting of macaw palm fruits [11], [12]. Recently, Grupioni et al. (2018) used the principles of mechanical vibration in a prototype developed for the semi-mechanized harvest of macaw palm.

Since each body has infinite natural frequencies, and these vary with the stage of maturation, one can select the fruits through this principle. Using a source of vibrational energy with the same natural frequency of the fruit, the phenomenon of resonance will occur, in which the fruits tended to a great amplitude of oscillation, causing fruit to detach. Therefore, it will be possible to select the fruits by the maturation stage [14]. However, the path that this vibrational energy passes is the source of excitation (machine), rachis, rachilla and fruit. That is, it is necessary to know the transmissibility of this energy throughout the rachis, for that, one has to first know the properties of the rachis. Thus, for understanding the dynamic phenomena involved during the harvesting by mechanical vibrations, it is necessary the geometric and physical knowledge of the plant structure and fruit.

The determination of physical and geometric properties of the macaw palm rachis is essential for the improvement of the harvesting and the emergence of new processing techniques, providing a knowledge basis for machine-plant interaction project. Mechanical properties of the macaw palm fruit-rachilla system were analyzed by Velloso et al. (2017) and Villar et al. (2017). In addition to mechanical properties, Rangel et al. (2019) also studied the geometric and physical properties of the macaw palm fruit-rachilla system.

In this context, considering the potential of the crop, the aim of this work was to determine and evaluate the geometric and physical properties of the rachis of macaw palm. This work proposes an investigation of the vibration transmissibility and frequency sweeping by means of mechanical vibrations on macaw palm rachis. In addition, in order to study the dynamic behaviour of the rachis of macaw palm, a numerical modal analysis was performed and validated from the frequency spectrum data obtained from frequency sweep tests. The results obtained from this study will constitute a basis of knowledge for aiding designers on development of harvesting and post-processing machines.

Material and methods

The research was carried out using macaw palm bunches collected at the Active Germplasm Bank (AGB) of the Federal University of Viçosa, this experimental area was also used in another works such as Villar et al. (2017),Velloso et al. (2017) and Grupioni et al. (2018). The Active Germplasm Bank is located at Experimental Farm in Araponga - MG, at 20° 40' South latitude and 42° 31' West longitude, Brazil. Samples of macaw palm rachis came from four sites: BGP 12 - Ibiá - Araxá; BGP 13 - Sítio Paraíso - Belo Horizonte; BGP 31 - Três Marias; BGP 53 - Lavras - São João Del Rey.

The samples were always collected in the morning and the tests performed during the same day of collection and also the day after. The ambient temperature of 20°C was maintained in the analytical laboratory.

The geometric dimensions, mass, volume, specific mass, tests of vibration transmissibility, frequency sweep and modulus of elasticity were determined for the samples at each stage of maturation (rachis with immature and mature fruits). It was considered the maturation stage of immature fruits aged 180 days and mature when the natural detachment of the fruits occurs. This work does not evaluate issues related from macaw palm fruits, it only evaluates properties related to the rachis from macaw palm bunches. The different maturation stages of the macaw palm fruits are mentioned throughout this work to distinguish the time of permanence of the rachis in the plant.

Geometric dimensions

For each stage of maturation, the macaw palm rachis was divided into three parts (Figure 1): lower, middle and upper third. The average length of each third was obtained by performing a length measurement of the longitudinal axis from end to end, using a measurement tape with 1 mm of precision.

Figure 1. Image of a sample of the macaw palm rachis partitioned in thirds.

The average diameter of each third was obtained by performing measurements of the diameter in five cross sections along the macaw palm rachis sample (third part of sample), equally distributed from the ends. The diameter was measured in the cross sections on the X and Y axis (Figure 2). The instrument used for measurement was an analog caliper with a precision of 0.01 mm.

Figure 2. Equidistant measurements of the third of the macaw palm rachis (A) and cross section of each third in the X and Y (B) axis.

Mass and volume

The average masses of each third part of the macaw palm rachis were determined using five trial bodies with 1.5 cm of height for each stage of maturation, using a digital scale, with a resolution of 0.01 g.

For the determination of the average volumes, macaw palm trial bodies, for each stage of maturation, was employed a 100 mL beaker, with a resolution of 1 mL. Volume measurements were performed by the immersion of a sample into water.

Specific mass

The specific mass was determined for the rachis samples by using the average mass and volume obtained experimentally.

Transmissibility test

Transmissibility tests were performed using a vibration system manufactured by Ling Dynamic Systems (LDS), which consisted of a signal generator, an amplifier model PA 1000 L coupled to a field power source model FPS-10 L , an electromagnetic shaker model V 555 M6-CE and a Dactron controller model Comet USB. In addition, an apparatus was developed for the purpose of coupling the sample of the rachis to the electromagnetic vibrator.

At first, the macaw palm rachis was set to the apparatus developed for attachment to the mobile base of the electromagnetic shaker, then the high-sensitivity acceleration piezoelectric transducers (100.7 mv/g (Eu)), were fixed vertically, along the rachis one at each midpoint of each monitored third (fractions of the rachis). Considering that the accelerometers were placed directly on the rachis and fixed with the aid of wax fixation and adhesive tape (Figure 3).

Figure 3. Electromagnetic shaker prepared for carrying out the vibration tests (A) and macaw palm rachis fixed for the test (B).

The transmissibility of the rachis was determined from a sinusoidal signal with frequency of 10 Hz and amplitudes 0.25 mm, both constants, when the frequency of the vibration that was used is the same as the natural frequency of the fruit, resonance occurs, even for small amplitudes. The way to evaluate the input of movement and the response of the system was performed from the value RMS (Root Mean Square) of the system. Thus, the transmissibility was determined for the rachis of bunches with predominance of fruits in the maturation stages of immature and mature from different sites.

For the measurement of the acceleration signals from the three fractions of the rachis, a National Instruments data acquisition system was used, consisting of a base chassisNI cDAQ-9174 and a four-channel NI 9234 module used for acceleration signal acquisition. The acquisition system was connected to a computer and managed by LabView version 5.0 software. Acceleration data, as a time function, were submitted to Fast Fourier Transform (FFT) for the determination of the frequency spectra. The rachis transmissibility was calculated by Equation 1.

![]() (1)

(1)

where,

T = transmissibility, %;

Yp = acceleration of the monitored point, m s-²;

Ye = acceleration of excitation, m s-².

Frequency sweep test

The frequency sweep test was carried out in a manner analogous to the transmissibility test, with the macaw palm rachis attached to the apparatus coupled to the electromagnetic shaker shown in Figure 3 (A). However, the analysis was performed from the acceleration of the system from a sinusoidal signal in the frequency range from 10 to 80 Hz and amplitude of 0.25 mm. Three high-sensitivity piezoelectric transducers (100.7 mv/g (Eu)) were installed at the measurement points shown in Figure 3 (B). The accelerometers were placed directly on the rachis and fixed with the aid of fixing wax and adhesive tape. The same plane and the same maturation stages were monitored.

For the measurement of the acceleration signals from the three monitoring points, a National Instruments data acquisition system was used, consisting of a base chassisNI cDAQ-9174 and a four-channel NI 9234 module. The acquisition system connected to the computer was managed by LabView software version 5.0. The natural frequencies were determined from the frequency spectra, after performing the Fast Fourier Transform (FFT). From the frequency sweep tests, the natural frequencies were identified considering the response amplification peaks on the frequency spectra.

Compression test

Simultaneously with the sweep test, the macaw palm rachis compression test was performed to obtain the modulus of elasticity for the immature and mature maturation stages. The objective of this study was to evaluate the parameters associated with the system stiffness and its correlation with the variation of the natural frequencies. For the compression tests, INSTRON 3360 Series Dual Column Table Frames universal testing machine was used, using 20 cylindrical test bodies for each maturation stage. These test bodies were made from the upper third of the rachis with a circular cross section of 20 mm in diameter and 15 mm in length.

The tests were performed by means of compression, and the test bodies were placed between two parallel flat circular plates, submitted to constant deformations of small magnitude on the two opposite faces of the test body. The loading rate provided was 15.0 mmmin-1, was monitored by Bluehill 3 software and managed by the computer coupled to the universal testing machine. The elasticity modulus of the rachis was calculated directly by the software.

Modeling of the rachis from macaw palm

The physical and geometric data were used to develop a model of the macaw palm rachis using 3D-CAD Fusion 360 software. The modeling was carried out for the immature and mature maturation stages scenarios. Two three-dimensional models, with different levels of detail, of the macaw palm rachis were developed. The first model was developedconsidering a less sophisticated geometry, a mesh refinement of 5942 nodes and 3238 elements. A second model was elaboratedconsidering a more sophisticated geometry,this model presented a mesh with 12426 nodes and 7046 elements. The discretization of both models was made from 10-node tetrahedral elements and the interpolation function used was a hyperbolic function. The final meshes used was obtained after a convergence test of models.

From the three-dimensional models of rachis, using the finite element method,a numerical modal analysis was performed. This analysis allowed the determination of eigenvalues (natural frequencies) and eigenvectors (mode shapes) of the system. Then, the flexural mode shapes, associated with the corresponding natural frequencies, were determined.

The model was validated comparing the average natural frequencies, that was determined from experimental frequency sweep tests, with the simulated natural frequencies, obtained from numerical modal analysis. Regardless the sites, the validation process was performed for the immature and mature stages of maturation, considering the frequency range from 10 to 80 Hz. The model validation will enable to improve the comprehension of the dynamic behavior of the rachis, during the excitation by mechanical vibrations on mechanized harvesting process.

Statistical analysis

The data of geometric dimensions, mass, volume, specific mass, vibration transmissibility and frequency sweep tests of the samples were submitted to analysis of variance, according to a completely randomized design, with two treatments (immature and mature stages of maturation stages of the fruits) and using three replicates. The effect of the stage of maturation on behavior of geometric and physical properties, the transmissibility and the natural frequencies of the systemwas studied by Tukey test, at a significance level of 5%. Statistical analyses were performed using Assistat Statistic software, version 7.7 beta [17].

Results and discussion

Geometric dimensions

Length

Significant differences were observed only between stages of maturation (Table 1). The stage of maturation of the fruits influences the rachis length, thus, it is possible to infer that the rachis length tends decrease when the stage of maturation pass from immature to mature. However, there was no significant difference in the length of the rachis for the sites.

Table 1. Macaw palm rachis length and average diameters for immature and mature stages of maturation.

| Stages of Maturation | Length (cm) | Diameter X(cm) | Diameter Y(cm) | |

| Immature Mature |

| 88.50 a 73.60 b | 2.75 a 2.31 b | 2.16 a 1.90 b |

Means followed by the same letter in the column are not significantly different by the Tukey test at 5% probability.

Similar behavior was observed by Ghavami and Marinho (2005) in bamboos of the Guaduaangustifolia species. The author detected a gradual decrease of the length from the base to the top due to advance of the stage of maturation. Between the sites, significant differences were not detected. The largest length belongs to the BGP 12 access, with the size of 91.85 cm and the shortest length belongs to the BGP 31 access with 70.85 cm.

Diameter

Considering the diameters were measured on X and Y axis, it was observed that there is statistical significant difference between the axes, where X axis tends to be larger than the Y axis.The average diameter found for the X axis was 2.52 cm and for the Y axis it was 2.03 cm.However, there was no significant difference for the diameter of the rachis for the means of sites.

The average diameters were analyzed regarding the stages of maturation and the results are presented in Table 1.The average diameters for the both axes tend to decrease when the stage of maturation pass from immature to mature stage. According to Carlin et al. (2008), in a study about sugarcane, verified that the change in diameter occurred due to cell stretching. Similar behavior was observed for macaw palm rachis, which can be explained due the cells elongation caused by the bunch weight.

The average diameters were analyzed regarding the comparison between the sites (Table 2).

Table 2. Average diameters on X and Y axes, mass, volume and specific mass from the macaw palm rachis to the sites.

| Sites | Diameter X(cm) | Diameter Y(cm) | Mass (g) | Volume (cm3) | Specific mass (g cm-3) |

| BGP 12 BGP 13 BGP 31 BGP 53 | 3.06 a 2.20 b 2.32 b 2.53 ab | 2.60 a 1.80 b 1.82 b 1.95 b | 13.14 a 6.35 b 7.00 ab 10.22 ab | 14.60 a 7.98 b 8.13 b 9.93 ab | 0.88 ab 0.75 b 0.83 ab 1.01 a |

Means followed by the same letter in the column are not significantly different by the Tukey test at 5% probability.

For the diameter on X axis, the BGP 12 site was larger than the BGP 13 and BGP 31 sites. As for the diameter on the Y axis, the BGP 12 site was larger than the diameters of the other sites.

The average diameters was evaluated considering the different parts of the macaw rachis (Table 3), which was divide in three thirds as illustrated in Figure 1.

Table 3. Average diameters on the X axis and Y axis, mass, volume and specific mass of the macaw palm rachis for the lower, middle and upper third

| Third | Diameter X (cm) | Diameter Y (cm) | Mass (g) | Volume (cm3) | Specific mass (g cm-3) |

| Lower Middle Upper | 3.40 a 2.64 b 1.56 c | 2.40 a 2.27 a 1.44 b | 12.41 a 9.50 ab 5.63 b | 12.82 a 10.70 ab 7.00 b | 0.98 a 0.89 ab 0.74 b |

Means followed by the same letter in the column are not significantly different by the Tukey test at 5% probability.

Analyzing the thirds of the macaw palm rachis, for the diameter on the X axis, it was observed significant differences between all parts of the rachis. The largest rachis diameter was determined for the lower third, followed by the middle and upper third. On the Y axis, there was not observed significant difference between the lower and middle thirds. The upper third presented significant difference in relation to the others. It can be noted that for the both axes the diameters tend to reduce from lower to upper third.

Mass and volume

The results obtained for masses and volumes, considering immature and mature stages of maturation, there were not observed significant differences for these parameters.

The results for the masses and volumes of the macaw palm rachis were analyzed for the sites (Table 2).Regarding the sites, for the mass, BGP 12 differed significantly from BGP 13, presenting an average mass higher. However, comparing BGP 12 site with BGP 31 and BGP 53, there was not observed significant difference between the mass values.

For the volumes, BGP 12 site presented an average volume higher than the others, differing significantly from the BGP 13 and BGP 31 sites, which did not differ from each other. However, BGP 12 site did not differ statistically of the BGP 53.

The results for the average masses and volumes were analyzed for the thirds of the macaw palm rachis (Table 3).From the results presented in Table 3 for mass and volume, it can be stated that the average mass of the lower third is almost three times greater than the average mass of the upper third. For the volume, it can be inferred that the volume of the thirds of the macaw palm rachis tends to be larger at the lower third of the bunch, precisely where the cut during the harvesting process occurs.

Specific mass

The results for the specific mass of the macaw palm rachis were analyzed considering immature and mature stages of maturation and the sites (Table 2). However, there were not observed significant differences were observed for the maturation stage.

For the sites, BGP 53 differed from the BGP 13, the average specific mass determined was 1.01 g cm-3, while for the BGP 13 was 0.75 g cm-3. This means that for the same amount of volume, the BGP 53 site will have a largest amount of mass. The sites BGP 12 and BGP 31, did not differ from the other sites.The results for specific mass were analyzed for the thirds of the macaw palm rachis (Table 3).

From the results presented in Table 3 forspecific mass, lower and upper thirds presented significant difference between them. Similarly the results for the volume of the rachis (Table 3), the specific mass tends to be larger at the lower third of the bunch. The lower third has the highest specific mass, 0.98 g cm-3, followed by the middle third, 0.89 g cm-3 and, finally, the upper third, 0.74 g cm-3.

Evaristo et al. (2017), verified that the physical and chemical characteristics of the fruits from macaw palm vary according to the region, this fact did not occur with the rachis from macaw palm bunches. As evidenced, the rachis from macaw palm belongs to distant regions themselves. However, the results found in the present study show that there is a similarity between the rachis from macaw palm for these different sites, evidencing a data pattern.

Physical properties of agriculture products can influence many steps of the mechanization process and post-harvesting of products [21], [22]. Thus, determination of physical and geometric properties of the macaw palm rachis is essential for the improvement of the harvesting and the emergence of new processing techniques [13], [23].Considering the harvesting of the macaw fruits, performed by machines, it is fundamental the determination of physical properties of all structures that constitute the bunches, in order to study and comprehend its mechanical behavior during the interaction with the machines.

Transmissibility test

During the monitoring of the immature and mature maturation stages, it can be inferred that there was no significantly difference for the results found. The transmissibility result indicates that for the same vibrational energy applied under the conditions proposed by the test, more energy will be transmitted to the macaw palm rachis during the mature ripening stage, about 46% of the initial value, while 32% of the initial energy will transmitted to the rachis.

Regarding the sites, the results of the transmissibility indicate that for the same vibrational energy applied under the conditions proposed by the test, more energy will be transmitted to the macaw palm rachis belonging to the BGP 12 site, with 50% of the initial energy value; while, the BGP 13 site, has the lowest average value of transmissibility, about 25%. The sites BGP 31 and BGP 53, hold intermediate values, being 46 and 42%, respectively.

According to Rao (2008), the transmissibility depends on factors such as frequency ratio and damping ratio. Considering that these parameters are similar for the different sites, since the biological material, that is, the macaw palm rachises are similar to each other. These have the same geometric conformations, subject to the same weather conditions, besides having the same type of management. Thus, it is expected that the magnitude of the transmissibility be close to the different sites. This fact is evidenced by Tukey test at a significance level of 5%, which did not detect significant statistical difference for the transmissibility. Due to the stiffness of the material, transmissibility tends to occur differently in different materials [25]. The stiffness that macaw palm rachis present was similar to that found by Villibor et al. (2019). The biological material has, in its composition, constituents that can function as shock absorbers of vibrational energy, such as cell membranes, cell walls and fibers[27].

It was observed that for the macaw palm rachis input frequency and amplitude, there was no amplification of the output response, different from that reported by Castro-Garcia et al. (2017) in oranges, evidencing better transmission of energy at low frequency, for both stages of maturation.

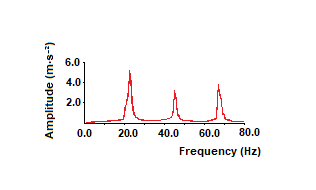

Frequency sweep tests

From the macaw palm rachis frequency sweep tests, performed for the 10 to 80 Hz range and amplitude of 0.25 mm, the natural frequencies were determined using the Fast Fourier Transform and frequency spectrum analysis. Figure 4 illustrates the frequency spectrum obtained for site BGP 31, from which the natural frequencies were extracted. The natural frequencies were identified considering the response amplification peaks on the frequency spectra. Similar methodology was applied for all sites considering immature and mature stages of maturation.

Figure 4. The frequency spectrum of the BGP 31 site showing three natural frequency peaks within the excitation range.

In Table 4 are present the experimental results obtained by the frequency sweep, which show the natural frequencies for the macaw palm rachis at different stages of maturation.

Table 4. Natural frequencies of the macaw palm rachis for the immature and mature maturation stages at the monitored points.

| Sites | Natural frequencies (Hz) | |

| Immature | Mature | |

| BGP 12 BGP 13 BGP 31 BGP 53 | 22.66, 45.26 and 67.85 22.65, 45.25 and 67.85 22.67, 45.26 and 67.86 22.65, 45.26 and 67.85 | 15.95, 22.68 and 45.27 15.90, 22.66 and 45.27 15.90, 22.66 and 45.27 15.72, 22.66 and 45.27 |

According to the results presented in Table 4, for each site, three natural frequencies were found within the frequency range scanned during the test. It is observed that all sites showed a similar behavior for natural frequencies, since, with the evolution of the maturation stage from immature to mature, the mode of vibration changed its magnitude from 22.66 to 15.90 Hz.

According to Rao (2008), the natural frequency is dependent of the stiffness and mass of the material, with the evolution of the maturation stage, there was a tendency of a decrease in the stiffness of the macaw palm rachis for the different maturation stages, once that a decrease of the modulus of elasticity occurred with the evolution of the maturation stage, going from 51.97 MPa when immature to 37.93 MPa when mature, implying in a lower stiffness of the material, resulting, therefore, in lower natural frequencies. However, BGP 53 site maintained similar natural frequency magnitudes for both maturation stages, which can be attributed by heterogeneity of the plant.

In addition, the results reported in Table 4 indicate that the natural frequency tends to decrease with the evolution of the maturation stage, which is interesting because in this way it is possible to separate the different maturation stages. Similar results were observed by Santos et al. (2010) and Villibor et al. (2016), both for coffee fruits, the authors were able to separate the different maturation stages of coffee from different natural frequencies. By means of mechanical vibrations, as well as (Pezzi and Caprara (2009) obtained for the grape crop and He et al. (2013), for the sweet cherry trees, it was observed amplitude amplification in the natural frequencies for the macaw palm rachis.

Modeling of the rachis from macaw palm

In Table 5are presented the results obtained for the frequencies in the mode of vibration of the rachis from macaw palm. Both models presented the response close to the experimental test. From the validation process, it can be observed that the immature stage of maturation presented an average error less than 5% for all natural frequencies evaluated.

Comparing the results presented in Table 5 with the results in Table 4,it can be observed that both models represent properly the dynamic behaviour of the macaw palm rachis. However, the error observed for mature stage of maturation (Table 6), for second natural frequency evaluated for models 1 and 2, may be associated with the lack of uniformity of the geometric and physical characteristics along the structure of the rachis.

Table 5. Frequencies of the macaw palm rachis for the Model 1 and Model 2.

| Stages of maturation | Frequencies (Hz) | |

| Model 1 | Model 2 | |

| Immature Mature | 23.40, 43.11 and 68.87 16.64, 30.62 and 48.81 | 23.41, 43.01 and 69.01 16.90, 31.02 and 49.47 |

Table 6.Validation error between simulated and experimental results for frequencies of the macaw palm rachis for the Model 1 and Model 2.

| Stages of maturation | Error (%) | |

| Model 1 | Model 2 | |

| Immature Mature | 3.1, 4.7 and 1.4 4.4, 25.9 and 7.2 | 3.2, 4.9 and 1.6 5.9, 26.9 and 8.4 |

The vibration modes (Figure 5), obtained for the macaw palm rachis models, corroborate the results obtained by the experimental test. Each mode of vibration is associated with a different natural frequency. The higher the printed frequency, the greater deflections will occur, resulting in possible stress concentration points. Note that the vibration modes are different for the same model; however, when the two models are compared, the vibration modes show similarities.

Figure 5.Vibration mode for macaw palm rachis in the immature maturation stage, model 1 (A, B, C) and model 2 (D, E, F).

The efficiency in detaching the fruit of the macaw palm occurs as the frequency of vibration that excites the plant is equal to or close to the vibration modes. In general, a more sophisticated mode of vibration of macaw palm can generate greater tensions favoring the detachment of the fruit [32]. In this way, the vibrational energy must be transmitted through the bunch to the fruit-rachilla system, similar to the coffee harvest by vibrations, in which the energy is transmitted to the fruit-stem system, resulting in the detachment [11], [12].

When the frequency of the vibration employed is the same as the natural frequency of the fruit. The amplitude amplification due to the phenomenon of resonance observed in the rachis reinforces the potential of using the principle of mechanical vibrations for the detachment of the fruit of the macaw palm bunches. In addition, it is important to note that this process has been used for the mechanized harvesting of several agricultural products, such as coffee[8], olive [9], pistachio [33], orange [28] and sweet cherry [31].

Conclusion

Under the conditions in which this work was conducted it can be concluded the length of the macaw palm rachis tended to decrease from immature to mature stage of maturation. The mass and volume of the macaw palm rachis tends to decrease along the length of the rachis. The specific mass of the macaw palm rachis tends to decrease from the lower third to the upper third. With the evolution of the stage of maturation from immature to mature, the first natural frequency, associated to the first flexural mode shape studied, changes in magnitude from 22.66 to 15.90Hz, which can be important during the mechanized harvesting by mechanical vibrations. Both models developed can represented properly the dynamic behavior of the macaw palm rachis and can be usedfor the study of the rachis in different scenarios.

References

[1] S. Y. Motoike et al., A cultura da macaúba: implantação e manejo de cultivos racionais, 1°. Viçosa: Editora UFV, 2013.

[2] P. E. F. Motta, N. Curi, A. T. Oliveira-Filho, and J. B. V. Gomes, "Ocorrência da macaúba em Minas Gerais: Relação com atributos climáticos, pedológicos e vegetacionais," Pesqui. Agropecu. Bras., vol. 37, no. 7, pp. 1023-1031, 2002, doi: 10.1590/s0100-204x2002000700017.

[3] T. P. Pires, E. S. Souza, K. N. Kuki, and S. Y. Motoike, "Ecophysiological traits of the macaw palm: A contribution towards the domestication of a novel oil crop," Ind. Crops Prod., vol. 44, pp. 200-210, 2013, doi: 10.1016/j.indcrop.2012.09.029.

[4] L. R. V. Conceição, L. M. Carneiro, D. S. Giordani, and H. F. Castro, "Synthesis of biodiesel from macaw palm oil using mesoporous solid catalyst comprising 12-molybdophosphoric acid and niobia," Renew. Energy, vol. 113, pp. 119-128, 2017, doi: 10.1016/j.renene.2017.05.080.

[5] A. B. Evaristo, J. A. S. Grossi, A. de C. O. Carneiro, L. D. Pimentel, S. Y. Motoike, and K. N. Kuki, "Actual and putative potentials of macauba palm as feedstock for solid biofuel production from residues," Biomass and Bioenergy, vol. 85, pp. 18-24, 2016, doi: 10.1016/j.biombioe.2015.11.024.

[6] M. C. Coimbra and N. Jorge, "Proximate composition of guariroba (Syagrus oleracea), jerivá (Syagrus romanzoffiana) and macaúba (Acrocomia aculeata) palm fruits," Food Res. Int., vol. 44, no. 7, pp. 2139-2142, 2011, doi: 10.1016/j.foodres.2011.03.032.

[7] S. Michelin et al., "Kinetics of ultrasound-assisted enzymatic biodiesel production from Macauba coconut oil," Renew. Energy, vol. 76, pp. 388-393, 2015, doi: 10.1016/j.renene.2014.11.067.

[8] A. L. F. Coelho, F. L. Santos, F. A. C. Pinto, and D. M. de Queiroz, "Detachment efficiency of fruits from coffee plants subjected to mechanical vibrations," Pesqui. Agropecuária Trop., vol. 45, no. 4, pp. 406-412, 2015, doi: 10.1590/1983-40632015v4536227.

[9] A. B. Dias, J. O. Peça, L. Santos, and A. Pinheiro, "A influência da poda mecânica na produção e na eficiência da colheita da azeitona por vibração The influence of mechanical pruning on olive production and shaker efficiency," Rev. Ciências Agrárias, vol. 30, no. 1, pp. 467-475, 2007, doi: 10.19084/rca.15440.

[10] J. P. B. Cunha, T. A. Machado, F. L. Santos, and L. M. Coelho, "Perdas na colheita de tomate industrial em função da regulagem da colhedora," Pesqui. Agropecu. Trop., vol. 44, no. 4, pp. 363-369, 2014, doi: 10.1590/s1983-40632014000400006.

[11] F. L. Santos, D. M. Queiroz, F. A. C. Pinto, and R. C. Resende, "Efeito da frequência e amplitude de vibração sobre a derriça de frutos de café Frequency and amplitude of vibration on coffee harvesting," Rev. Bras. Eng. Agrícola e Ambient., no. 67, pp. 425-431, 2010.

[12] F. L. Santos, D. M. Queiroz, D. S. M. Valente, and A. L. F. Coelho, "Simulação do comportamento dinâmico do sistema fruto-pedúnculo do café empregando o método de elementos finitos," Acta Sci. - Technol., vol. 37, no. 1, pp. 11-17, 2015, doi: 10.4025/actascitechnol.v37i1.19814.

[13] C. M. F. Grupioni, F. L. Santos, H. C. Fernandes, D. S. M. Valente, and F. A. C. Pinto, "Development and evaluation of operational performance of macaw fruits semi-mechanized harvester by means mechanical vibrations principle," Semin. Agrar., vol. 39, no. 2, pp. 497-510, 2018, doi: 10.5433/1679-0359.2018v39n2p497.

[14] N. S. Velloso, F. L. Santos, F. A. C. Pinto, F. M. M. Villar, and D. S. M. Valente, "Mechanical properties of the macaw palm fruit-rachilla system1 [Propriedades mecânicas do sistema fruto-ráquila de macaúba]," Pesqui. Agropecu. Trop., vol. 47, no. 2, pp. 218-225, 2017, doi: 10.1590/1983-40632016v4745792.

[15] F. M. M. Villar, F. A. C. Pinto, F. L. Santos, J. A. S. Grossi, and N. S. Velloso, "Elasticity modulus and damping ratio of macaw palm rachillas," Ciência Rural, vol. 47, no. 2, pp. 1-6, 2017, doi: 10.1590/0103-8478cr20160289.

[16] J. P. Rangel, D. M. Queiroz, F. A. Carvalho Pinto, F. L. Santos, and D. S. M. Valente, "Geometric, Physical and Mechanical Properties of the Fruit-rachilla of the Macauba Palm (Acrocomia aculeata) Considering Different Sampling Sites in the State of Minas Gerais in Brazil," J. Exp. Agric. Int., vol. 38, no. 3, pp. 1-6, 2019, doi: 10.9734/jeai/2019/v38i330301.

[17] F. A. S. e Silva and C. A. V. Azevedo, "The Assistat Software Version 7.7 and its use in the analysis of experimental data," African J. Agric. Res., vol. 11, no. 39, pp. 3733-3740, 2016, doi: 10.5897/ajar2016.11522.

[18] K. Ghavami and A. B. Marinho, "Propriedades físicas e mecânicas do colmo inteiro do bambu da espécie Guadua angustifolia," Rev. Bras. Eng. Agrícola e Ambient., vol. 9, no. 1, pp. 107-114, 2005, doi: 10.1590/s1415-43662005000100016.

[19] S. D. Carlin, M. A. Silva, and R. Rossetto, "Parâmetros biométricos e produtividade da cana-de- açúcar após tombamento dos colmos," Bragantia, vol. 67, no. 4, pp. 845-853, 2008, doi: 10.1590/s0006-87052008000400006.

[20] A. B. Evaristo, S. D. M. Goulart, A. D. Martins, L. D. Pimentel, and J. A. S. Grossi, "Caracterização Fisico-Química De Frutos De Macaúba Provenientes De Três Regiões Do Estado De Minas Gerais," Rev. Agrotecnologia - Agrotec, vol. 8, no. 2, p. 81, 2017, doi: 10.12971/2179-5959/agrotecnologia.v8n2p81-92.

[21] A. L. F. Coelho, F. L. Santos, F. A. C. Pinto, and D. M. Queiroz, "Determination of geometric, physical and mechanical properties of coffee fruit-stem-branch system," Rev. Bras. Eng. Agric. e Ambient., vol. 19, no. 3, pp. 286-292, 2015, doi: 10.1590/1807-1929/agriambi.v19n3p286-292.

[22] P. R. Ferrari and M. D. Ferreira, "Qualidade da classificação do tomate de mesa em unidades de beneficiamento," Eng. Agrícola, vol. 27, no. 2, pp. 579-586, 2007.

[23] A. G. Costa, F. A. C. Pinto, R. B. Alves Júnior, S. Y. Motoike, and L. M. N. Gracia, "Determination of macaw fruit harvest period by biospeckle laser technique," African J. Agric. Res., vol. 12, no. 9, pp. 674-683, 2017, doi: 10.5897/ajar2016.12039.

[24] S. Rao, Vibrações Mecânicas, 4°. São Paulo: Pearson, 2008.

[25] R. C. Hibbeler, Resistência dos materiais, 7°. São Paulo: Pearson Prentice Hall, 2010.

[26] G. P. Villibor, F. L. Santos, D. M. Queiroz, J. K. Khoury Junior, and F. A. C. Pinto, "Dynamic behavior of coffee fruit-stem system using modeling of flexible bodies," Comput. Electron. Agric., vol. 166, no. May 2018, p. 105009, 2019, doi: 10.1016/j.compag.2019.105009.

[27] E. Oliveira, B. R. Vital, A. S. Pimenta, R. M. Della Lucia, A. M. M. Ladeira, and A. C. O. Carneiro, "Estrutura anatômica da madeira e qualidade do carvão de Mimosa tenuiflora (Willd.) Poir," Rev. Árvore, vol. 30, no. 2, pp. 311-318, 2006, doi: 10.1590/s0100-67622006000200018.

[28] S. Castro-Garcia, G. L. Blanco-Roldán, L. Ferguson, E. J. González-Sánchez, and J. A. Gil-Ribes, "Frequency response of late-season 'Valencia' orange to selective harvesting by vibration for juice industry," Biosyst. Eng., vol. 155, pp. 77-83, 2017, doi: 10.1016/j.biosystemseng.2016.11.012.

[29] G. P. Villibor, F. L. Santos, D. M. Queiroz, J. K. Khoury Junior, and F. A. C. Pinto, "Determinação das propriedades modais do sistema fruto-pedúnculo do café por vídeos de alta velocidade e processamento de imagens digitais," Acta Sci. - Technol., vol. 38, no. 1, pp. 41-48, 2016, doi: 10.4025/actascitechnol.v38i1.27344.

[30] F. Pezzi and C. Caprara, "Mechanical grape harvesting: Investigation of the transmission of vibrations," Biosyst. Eng., vol. 103, no. 3, pp. 281-286, 2009, doi: 10.1016/j.biosystemseng.2009.04.002.

[31] L. He, J. Zhou, X. Du, D. Chen, Q. Zhang, and M. Karkee, "Energy efficacy analysis of a mechanical shaker insweet cherry harvesting," Biosyst. Eng., vol. 116, no. 4, pp. 309-315, 2013, doi: 10.1016/j.biosystemseng.2013.08.013.

[32] H. J. Ciro, "COFFEE HARVESTING I: DETERMINATION OF THE NATURAL FREQUENCIES OF THE FRUIT STEM SYSTEM IN COFFEE TREES," Appl. Eng. Agric., vol. 17, no. 4, pp. 475-479, 2001.

[33] R. Polat, I. Gezer, M. Guner, E. Dursun, D. Erdogan, and H. C. Bilim, "Mechanical harvesting of pistachio nuts," J. Food Eng., vol. 79, no. 4, pp. 1131-1135, 2007, doi: 10.1016/j.jfoodeng.2006.03.023.