Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Acta Odontológica Latinoamericana

versión On-line ISSN 1852-4834

Acta odontol. latinoam. vol.27 no.3 Buenos Aires dic. 2014

ARTÍCULOS ORIGINALES

In vitro evaluation of the film thickness of self-etching resin cements

Julio Chávez-Lozada, María del Carmen Urquía-Morales

Department of Operative Dentistry, I "B". School of Dentistry, University of Córdoba, Argentina.

CORRESPONDENCE Dr. Julio Chavez Lozada, Achaval Rodriguez N° 241. Cordoba, Argentina. juliochavezlozada@yahoo.com.ar

ABSTRACT

The aim of this study was to evaluate the film thickness of selfetching resin cement. The following materials were used: Group1, Relyx U100 (3M /ESPE); Group 2, BisCem (Bisco); Group 3, Max Cem (Kerr); Group 4, Set (SDI) and Group 5, Relyx ARC (3M/ESPE) as control. Two 5.4 x 76.2 x 1 mm glass slides were marked in the center to identify the area where the material would be placed. A volume of 0.05 ml was used for each specimen material. After 1, 3 and 6 minutes, a 50 N load was applied for one minute. The thickness of each specimen was then measured using a digital micrometer to the nearest 1 μm; (Digimatic, Mitutoyo Corporation, Japan.). Data were analyzed using ANOVA and Bonferroni's multiple comparison tests. No significant difference was found between the materials tested (p = 0.0921) or material/time interaction (p = 0.0864), but there were differences in the time factor (p = 0.0001). At one minute, the thinnest film was Relyx ARC (control) (14 μm), followed by Relyx U100 (17 μm), and Maxcem and SeT (19 μm). At 3 minutes, Group 5 (control) was also the thinnest film (19 μm), followed by Group 1 (21 μm), Group 3 (25 μm), Group 2 (29 μm), and Group 4 (31 μm). At 6 minutes, Group 4 was the thinnest (34 μm), followed by Group 1 (38 μm), Group 5 (40 μm), Group 2 (41 μm) and Group 3 (42 μm). The film thickness of resin cements was influenced by time and polymerization reaction. The film thickness of self-etching cements was low.

Key words: Resin cements; Film thickness.

RESUMEN

Evaluación in vitro del espesor de película de cementos resinosos de autograbado

El objetivo fue evaluar el espesor de pelicula de cementos resinosos de autograbado. Se utilizaron los siguientes materiales Grupo 1: Relyx U100 (3M /ESPE), Grupo 2 BisCem (Bisco), Grupo 3: Max Cem (Kerr), Grupo 4: Set (SDI) y Grupo 5: Relyx ARC (3M/ESPE) como control. Se emplearon dos superficies de vidrio de 25.4 x 76.2 x 1 mm., senaladas en su parte media con una marca, para ubicar el material sobre la misma area. Se utilizo un volumen de 0,05 ml. de material para cada probeta. Se espero 1, 3 o 6 minutos para aplicar una carga de 50 N durante 1 minuto. Trascurrido dicho lapso cada probeta se sometio a lectura de espesor de pelicula utilizando un micrometro digital, con una precision de 1um; (Digimatic, Mitutoyo Corporation, Japon.). Los datos fueron analizados mediante ANOVA y test de comparaciones multiples de Bonferroni, no hubo diferencias significativas entre los materiales evaluados (p = 0,0921), ni en la interaccion material / tiempo (p = 0,0864), pero si existieron diferencias en relacion al factor tiempo (p = 0,0001). Al minuto el menor espesor de pelicula correspondio a Relyx ARC (control) con un valor de 14 μm, seguido por Relyx U100 (17 μm), BisCem, Maxcem y SeT presentaron un valor de 19 μm. A los 3 minutos el grupo 5 (control) presento tambien el menor espesor (19 μm), seguido por el grupo 1 (21 μm), grupo 3 (25 μm), grupo 2 (29 μm), y grupo 4 (31 um). A los 6 minutos el grupo 4 mostro el menor valor con 34 μm, seguido por grupo 1 (38 μm), grupo 5 (40 μm), grupo 2 (41 μm) y grupo 3 (42 μm). El espesor de pelicula de los cementos resinosos se vio influenciado por el tiempo y reaccion de polimerizacion. Los cementos de autograbado presentaron un reducido espesor de pelicula.

Palabras clave: Cementos resinosos; Espesor de pelicula.

INTRODUCTION

Luting agents are used to fix rigid restorations to teeth and prevent them from becoming detached, and to achieve an adequate marginal seal that will ensure that the restorations last inside the mouth1,2 . It is important to select and use luting agents correctly because many of their advantages are lost if the wrong system is used2. Composite or resin cements have interesting physical and mechanical properties compared to other dental cements such as zinc phosphate3,4. These advantages include low solubility, high flexural resistance, low marginal leakage and better retention5- 8. Another important factor to consider is film thickness in order to achieve a rigid restoration without alterations in the seating, to prevent mar- ginal misfit and alterations in its location in the occlusal direction. Adequate cement thickness (40- 50 μm)9,10 and an appropriate volume of material reduce the need to create escape routes, and optimize the seating of the restoration, improve marginal fit, provides less exposure of the cement to mouth fluids and minimize contraction stress during polymerization by reducing the interface.11-13

Film thickness may directly affect the long-term clinical success of cemented restorations. Various factors affecting thickness have been analyzed, including physical surface phenomena, chemical interactions between materials and tooth, pressure applied upon seating the restoration, how the different materials are handled, dead spaces within the restoration, time between mixing and seating the rigid restoration14-16.

When attaching a restoration, during the luting technique it is necessary to consider both the intensity and the duration of the seating force of the structure to be attached. It is advisable to apply high pressure, which should be maintained until the material hardens, and to manipulate the material quickly and carefully in order to improve its physical, chemical and mechanical properties17.

Resin cement composition is based on a Bis-GMA, UDMA, TEGDMA type resin matrix with an inorganic reinforcing filler of glass, zirconium, silica or silicates, usually 50%-70% by weight6. Self-etching resin adhesive cements have recently been introduced on the market. They do not require treatment of the tooth structure, which incorporates monomers with phosphoric acid groups (phosphorylated methacrylates) whose acidity enables demineralization of the tooth tissue and adhesion18. This simplifies the technique and saves operational time for the adhesive procedure19,20.

Progress in the field of research, technological development and the production of a wide range of self-etching adhesive cements led us to conduct this study in order to determine whether these cements have one of the desirable properties of cementing agents: thin film.

MATERIALS AND METHODS

The testing method was adapted from ISO standard 4049:2000 for polymer-based restorative and luting dental materials10. The tests were performed in a laboratory under controlled temperature (21°C 2°C) and relative moisture ambient relative humidity (60% 10°C). Table 1 shows the experimental materials used in Groups 1 to 4 - self-conditioning resin cements, and Group 5 (control) - a conventional resin cement.

Table 1: Experimental materials.

Two 25.4 mm x 76.2mm x 1 mm glass slides were used. Their centers were marked so that the material would always be placed in the same area. An additional mark was made at one end of the slides to ensure the same orientation for all samples (Fig.1). The thickness of paired glass slides was measured with a digital micrometer (Digimatic, Mitutoyo Corporation, Japan) to the nearest 1 μm. Materials were handled following the instructions of the respective manufacturers.

Fig. 1: Marks on glass slides - in the center for placing the cement and at the top end for positioning.

A tuberculin syringe with modified tip (Figs. 2 and 3) was used to measure 0.05 ml of each material. The mixture was placed on a glass slide and covered with another. After 1, 3 and 6 minutes, constant pressure of 50 N was applied for 1 minute using a dynamometer (Fig. 4), after which the film thickness of each sample was measured using a digital micrometer (Fig. 5). Thickness was measured at three points for each specimen and time variable, and the arithmetic mean calculated. Sample size was three specimens for each material and time unit (n=9). The values were subject to analysis of factorial variance and Bonferroni's multiple comparisons test.

Fig. 2: Tuberculin type syringe with modified tip for standardization of the amount of luting agent to be used.

Fig. 3: Mixture loaded in the syringe.

Fig. 4: 50 N constant load applied by dynamometer.

Fig. 5: Measuring luting agent film thickness with a digital micrometer (Mitutoyo, Japan).

RESULTS

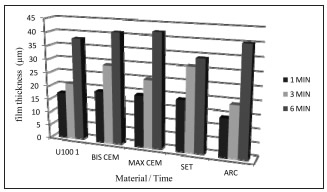

Table 2 shows the mean values for film thickness, standard deviations for each experimental material and study times. The thinnest film was Relyx ARC (control) (14 μm), followed by Relyx U100 (17 μm), and BisCem, Maxcem and SeT (19 μm). At 3 minutes, Group 5 (control) was also the thinnest (19 μm), followed in increasing order by Group 1 (21 μm), Group 3 (25 μm), Group 2 (29 μm), and Group 4 (31 um). At 6 minutes, Group 4 was thinnest (34 μm), followed by Group 1 (38 μm), Group 5 (40 μm), Group 2 (41 μm) and finally Group 3 (42 μm). These values are shown in Fig. 6. Analysis of variance (Table 3) showed no statistically significant difference between materials (p = 0.0921) or material/time interaction (p = 0.0864), but there were significant differences with regard to time (p = 0.0001).

Table 2: Arithmetic means and standard deviation.

Table 3: Analysis of variance (SS type III).

Fig. 6: Graphic representation of film thickness results in μm (mean values), expressed in Table 2.

Bonferroni's multiple comparison test shows significant differences in time for the different experimental materials (Table 4).

Table 4: Bonferroni's multiple comparison test.

DISCUSSION

Resin cements are used to achieve attachment and sealing when a rigid structure is attached to tooth tissues. These materials need to have adequate consistency - fluid enough according to the restoration to be cemented - achieving appropriate film thickness8,21-23. Cement spreading is a property that depends on the time factor when there is a reaction that determines its setting or change in state during that time7. ISO standard 4049/2000 for polymer-based dental materials10 establishes that polymer-based dental cement films should be less than 50 μm thick. Accordingly, this study used three waiting times: 1,3 and 6 minutes after preparing the mixture, followed by the application of a 50 N load. Our results showed significant differences for the time variable (p = 0.0001) for 6 minutes, compared to 1 and 3 minutes after preparing the mixture, for all experimental materials. For all the self-etching cements evaluated and the conventional resin cement, viscosity was found to increase with time from the mixture. Thus, it should be highlighted that the operator should work quickly and effectively to achieve adequate film thickness. Manufacturers' instructions provide working times for their products, specifying mixing time, working time, photopolmerization time and finally, self-polymerization time. The sum of all these times was not less than 7 minutes for any of the groups evaluated. This may explain why the thickness was less than 50 μm at 6 minutes for all groups. Still, film thickness increases significantly with time, so that timing should never be exceeded, since the viscosity of the material will increase, with a consequent increase in film thickness, reducing marginal fit and inducing greater polymerization tension leading to subsequent adhesive failure of the restoration16,24-26.

Resin cement film thickness is also influenced by the load applied during restoration seating. A load of sufficient strength and duration should be used to achieve a thin layer of material between the parts to be joined until the material hardens completelyl7,12,16,26,27. This study obtained film thicknesses of 14 μm to 19 μm, at 1 minute, 19 μm - 31 μm at 3 minutes and 34 μm to 42 μm at 6 minutes by applying a 50 N load for one minute, from which it may be inferred that the self-etching luting agents studied meet one of the desirable properties for resinous cements, which is thin films, with no significant difference among the different experimental materials (p = 0.0921). These results agree with those of Kious AR, Roberts HW, and Brackett WW 25. Moreover, Moraes RR, Boscato N, Jardim PS, Means with a letter in common are not significantly different (p<= 0,05) Schneider LFJ 26 report that self-adhesive resin cements polymerize more slowly and with a lower degree of final conversion, providing more time during seating, which might explain the low thicknesses recorded, even at 6 minutes, when they were not greater than 50 μm.

The viscosity of self-etching cements is different from that of traditional cements, which is related to the percentage of inorganic reinforcement filler and varies according to the material selected28-30. According to Han L, Okamoto A, Fukushima M and Okiji T 2, a lower percentage of filler particles may provide a thinner film thickness, according to the results reported in their paper. Of the luting agents evaluated in this study, the thinnest film was obtained with Relyx ARC (14 μm at 1 minute), which contains 67.5% inorganic filler by weight and particle size 1.5 μm. The others ranged from 17 μm to 19 μm at 1 minute, with the following filler percentages: Relyx U 100 (70%), Bis Cem (60%), Max Cem (66%) and SeT (65%). This may confirm the above.

CONCLUSIONS

Resinous luting agent film thickness was affected by the time from mixture and finally by the polymerization reaction. Self-etching luting agents produced thin films.

ACKNOWLEDGMENTS

We would like to thank Dr. Vivian Zahra and Dr. Andrea Kaplan of the Dental Materials Department at University of Buenos Aires for their cooperation in this study.

1. Bertacchini S, Cipponeri K. Medios cementantes adhesivos. Rev Asoc Odontol Argent 2002;90:124-130. [ Links ]

2. Han L, Okamoto A, Fukushima M, Okiji T. Evaluation of physical properties and surface degradation of self-adhesive resin cements. Dent mater J 2007;26:906-914. [ Links ]

3. White SN. Adhesive cements and cementation. J Calif Dent Assoc 1993;21:30-37. [ Links ]

4. White SN, Yu Z, Kipnis V. Effect of seating forces on film thickness of new adhesive luting agents. J Prosthet Dent 1992;68:476-481. [ Links ]

5. Attar N, Tam LE, Mc Comb D. Mechanical and physical properties of contemporary dental luting agents. J Prosthet Dent 2003;89:127-134. [ Links ]

6. Diaz Arnold AM, Vargas MA, Haselton DR. Current status of luting agents for fixed prosthodontics. J Prosthet Dent 1999;81:135-141. [ Links ]

7. Rosenstiel SF, Land MF, Crispin BJ. Dental luting agents: A review of the current literature. J Prosthet Dent 1998;80: 280-301. [ Links ]

8. White SN, Kipnis VJ. Effect of adhesive luting agents on the marginal seating of cast restorations. J Prosthet Dent 1993; 69:28-31. [ Links ]

9. American National Standars Institution / American Dental Association. ANSI/ADA Spec No 96 for dental waterbased cements; 1993. URL: http://www.ada.org/en/scienceresearch/dental-standards. [ Links ]

10. ISO 4049: 2000 E. Dentistry-polymer-based filling, restorative and luting materials, 3rd edition, 2000. [ Links ]

11. van der Vyver PJ, de Wet FA. The film thickness of five adhesive resin cement. SADJ 1998; 53: 377-379. [ Links ]

12. White SN, Yu Z, Kipnis V. Film thickness of new adhesive luting agents. J Prosthet Dent 1992; 67: 782-785. [ Links ]

13. Zahra VN, Macchi RL. Consistencia de cementos resinosos y asentamiento de restauraciones rigidas. Rev Asoc Odontol Argent 2007; 95: 205-209. [ Links ]

14. Gomes JC. La adhesion en prostodoncia fija, Cap.14. En: Henestroza HG, Borgia E, Busato ALS, Carvalho RM, Corts JP, de Souza Costa CA, Edelberg M, Garone W. Adhesion en Odontologia Restauradora. Curitiba, Brasil, Ed. MAIO 2003; 367-389. [ Links ]

15. Macchi RL, Kaplan AE. Incrustaciones, coronas y puentes. Cap. IV. En: Macchi RL. Materiales Dentales. 3a ed. Buenos Aires, Argentina, Ed Medica Panamericana 2000; 257-311. [ Links ]

16. Zahra VN, Abate PF, Almeida Chetti V, Macchi RL. Evaluacion del espesor de pelicula de cementos resinosos. Rev Asoc Odontol Argent 2003; 91:479-482. [ Links ]

17. Bertoldi Hepburn A. Fijacion de estructuras rigidas en odontologia restauradora. Una revision general. Rev Asoc Odontol Argent 2007;95:403-416. [ Links ]

18. Goracci C, Cury AH, Cantoro A, Papacchini F, Tay FR, Ferrari M. Microtensile bond strength and interfacial properties of self-etching and self-adhesive resin cements used to lute composite onlays under different seating forces. J Adhes Dent 2006; 8: 327-335. [ Links ]

19. Hikita K, Van Meerbeek B, De Munck J, Ikeda T, Van Landuyt K, Maida T, Lambrechts P, Peumans M. Bonding effectiveness of adhesive luting agents to enamel and dentin. Dent Mater 2007;23:71-80. [ Links ]

20. Audenino G, Bresciano ME, Bassi F, Carossa S. In vitro evaluation of fit of adhesively luted ceramic inlays. Int J Prosthodont 1999; 81:135-141. [ Links ]

21. Piemjai M. Effect of seating force, margin desing and cement on marginal seal and retention of complete metal crowns. Int J Prosthodont 2001;14:412-416. [ Links ]

22. van der Vyver PJ, Wet FA. The film thickness of five adhesive resin cements. SADJ 1998;53:377-379. [ Links ]

23. Yu Z, Strutz JM, Kipnis V, White SN. Effect of dynamic loading methods on cement film thickness in vitro. Int J Prosth 1995;4:251-255. [ Links ]

24. Vrochari AD, Eliades G, Hellwig E, Wrbas KT. Curing efficiency of four self-etching, self-adhesive resin cements. Dent Mater 2009;25:1104-1108. [ Links ]

25. Kious AR, Roberts HW, Brackett WW. Film thicknesses of recently introduced luting cements. J Prosthet Dent 2009; 101:189-192. [ Links ]

26. Moraes RR, Boscato N, Jardim PS, Schneider LFJ. Dual and self curing potential of self-adhesive resin cements as thin films. Oper Dent 2011;36:635-642. [ Links ]

27. Zahra VN, Macchi RL, Espesor de pelicula de cementos resinosos bajo la aplicacion de diferentes cargas. Rev Asoc Odontol Argent 2006;94:307-310. [ Links ]

28. Macchi RL. Cementos cap 11. En: Macchi RL. Materiales Dentales. 4°ed. Buenos Aires, Argentina, Ed Medica Panamericana 2007:149-153. [ Links ]

29. Bertoldi Hepburn A. Fijacion de estructuras rigidas en odontologia restauradora. Cap. 9. En: Bertoldi Hepburn A. Rehabilitacion Posendodontica, Base Racional y consideraciones esteticas. Buenos Aires, Argentina, Ed. Medica Panamericana 2012; 285-304. [ Links ]

30. Ferracane JL, Stansbury JW, Burke FJ. Self-adhesive resin cements - chemistry, properties and clinical considerations. J Oral Rehabil 2011; 38: 295-314. [ Links ]