Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Acta Odontológica Latinoamericana

On-line version ISSN 1852-4834

Acta odontol. latinoam. vol.29 no.2 Buenos Aires Sept. 2016

ARTÍCULOS ORIGINALES

Comparison of frictional resistance among conventional, active and passive self-ligating brackets with different combinations of arch wires: a finite elements study

Sandra L. Gómez1, Yesid Montoya2,3, Nora L. Garcia1, Ana L. Virgen1, Javier E. Botero1

1 Faculty of Dentistry, University of Antioquia, Medellin, Colombia.

2 School of Engineering of Antioquia, Medellin, Colombia.

3 Centro de especialistas en salud (CES ) University of Antioquia, Medellin, Colombia.

CORRESPONDENCE: Dra. Sandra Liliana Gomez Facultad de Odontologia, Universidad de Antioquia, Calle 70 No. 5221, Medellin, Colombia. Email: sandragomezortodonciaudea@gmail.com

ABSTRACT

The aim of this study was to compare frictional resistance among conventional, passive and active selfligating brackets using Finite Elements Analysis (FEA). Seventynine (79) slide tests were performed by combining an upper first bicuspid conventional bracket, 0.018” stainless steel wires and 0.010” ligature by means of an INSTRON 3345 load system to obtain average maximum static frictional resistance (MSFR). This value was compared to the FR (frictional resistance) obtained by simulation of a slide of the same combination by FEA following conventional bracket modeling by means of Computer Aided Design (CAD). Once the FEA was validated, bracket CADs were designed (upper right first bicuspid conventional, active and passive selfligating bracket) and bracket properties calculated. MSFR was compared among conventional, active and passive selfligating brackets with different alloys and archwire cross sections such as 0.018”, 0.019” x 0.025”and 0.020” x 0.020”. Passive selfligating brackets had the lowest MSFR, followed by conventional brackets and active selfligating brackets. In conventional brackets, a 0.018” archwire produced a linear pattern of stress with maximum concentration at the center. Conversely, stress in 0.020 x 0.020” and 0.019 x 0.025” archwires was distributed across the width of the slot. The highest normal forces were 1.53 N for the 0.018” archwire, 4.85 N for the 0.020 x 0.020” archwire and 8.18 N for the 0.019 x 0.025” archwire. Passive selfligating brackets presented less frictional resistance than conventional and active selfligating brackets. Regardless of bracket type, greater contact area between the slot and the archwire and the spring clip increased frictional resistance.

Key words: Friction; Orthodontic brackets; Finite element analysis.

RESUMEN

Comparacion de la resistencia friccional entre brackets convencionales, de autoligado activo y pasivo con diferentes combinaciones de arcos: un estudio de elementos finitos

El objetivo de este estudio fue comparar la resistencia friccional entre brackets convencionales, de autoligado pasivo y activo por medio del método de elementos finitos (MEF). Se realizaron setenta y nueve (79) deslizamientos combinando brackets convencionales de primer bicúspide superior con arcos de acero de 0,018” y ligadura metálica de 0,010” en una máquina INSTRON 3345, obteniendo el promedio de la resistencia estática máxima (REM). Este valor fue comparado con la resistencia friccional obtenida por simulación de un deslizamiento de la misma combinación por medio de MEF previo diseño asistido por computador (CAD) del bracket convencional. Una vez se validó MEF, se realizaron diseños CAD de los brackets (convencional, autoligado activo y pasivo de primer bicúspide superior derecho) y cálculos de sus propiedades. Se realizó una comparación entre brackets convencionales, brackets de autoligado activo y pasivo con diferentes aleaciones y secciones cruzadas de alambre 0.018”, 0.019” x 0.025” y 0.020” x 0.020”. Los brackets de autoligado pasivo mostraron la menor REM, seguidos de los brackets convencionales y finalmente los brackets de autoligado activo. En los brackets convencionales, el arco de 0,018” produjo un patrón lineal de stress en el fondo de la ranura, con su máxima concentración en el centro. Por el contrario, los arcos de 0.020” x 0.020” y 0.019 x 0.025” tuvieron una distribución de esfuerzos a través del ancho de la ranura. La mayor fuerza normal en los brackets convencionales fue para el arco 0.019”x 0.025” (8.18N), seguido por el arco 0.020 x 0.020” (4.85N) y finalmente el arco 0.018” (1.53N). Los brackets de autoligado pasivo presentaron menos resistencia friccional que los brackets convencionales y autoligado activo respectivamente. Independiente del tipo de bracket, una mayor área de contacto entre la ranura del bracket y el arco, y el spring clip aumentaron la resistencia friccional.

Palabras clave: Fricción; Brackets; Análisis de elementos finitos.

INTRODUCTION

Frictional force is defined as the tangential force produced at the interface between two bodies, which opposes the sliding of one on the other. Friction in orthodontics occurs between bracket, wire and ligature. The resulting frictional resistance reduces the efficiency of orthodontic treatment due to loss in the total force applied (21% to 60%)1. Greater force is therefore required to move teeth. However, forces of high magnitude can cause biological damage such as root resorption and pulp necrosis1. Archwire size and type of alloy, bracket size and material, the slot, ligating forces, interbracket distance, saliva and other factors can have direct or indirect influence on frictional resistance2,3. Selfligating brackets emerged in the mid 1930s, becoming popular in the 1980s4, and are presented as an alternative to conventional brackets for providing greater efficiency in the orthodontic treatment. Greater efficiency is based on reduced friction between bracket and archwire, shorter dental appointments and increased patient comfort, acceptance and cooperation3.

Several in vitro studies agree that selfligating brackets generate lower frictional resistance than conventional brackets when used with a small, round arch wires5-11. Further differences are reported between active and passive selfligating brackets12-14. However, these studies showed that the reduction in frictional force of selfligating brackets compared to conventional brackets is limited to certain archwire sizes in a 0.022” slot, after which frictional resistance is similar3, 5 or greater 10. The study of frictional force and stress distribution in selfligating brackets will provide additional evidence for their rational use. Finite element analysis (FEA) is a general numerical method for approximating solutions from partial differential equations. It has been applied in dental research, facilitating the solution of complex biomechanical interactions. However, its use in orthodontic research is scarce.

The aim of this study was to compare frictional resistance between conventional and selfligating brackets using different alloys and archwire cross sections by FEA.

MATERIALS AND METHODS

This study was conducted in three phases: experimental, validation and FEA modeling.

Experimental phase

We used upper right first bicuspid preadjusted conventional stainless steel brackets (0.022” x0.028” Mini Diamond Ormco, Glendora CA, USA) combined with stainless steel round arch wire 0.018” (Stainless Steel, SDS, Ormco, Glendora CA, USA) and stainless steel ligatures 0.010” (SDS Ormco, Glendora CA, USA). A tensile and compressive test was performed on the wire and on the bracket using a 3345 INSTRON machine with a 5000N}1N cell load at a speed of 5mm/min to obtain the elastic modulus (Young modulus) of each material. Poisson ratio was set to a constant of 0.3 (Table 1).

Table 1: Properties of brackets and wires.

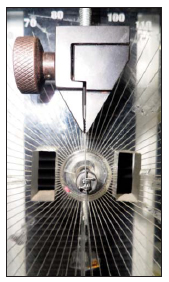

An acrylic structure adapted to the machine fixed one upper right first bicuspid bracket with vertical arrangement of the slot (Fig 1). Each arch wire was ligated to the bracket with stainless steel ligatures and then slid along the slot at a speed of 5mm/min for 2minutes with a cell load of 10}0.01N. Maximum static frictional resistance (MSFR) was measured. The experiment was repeated 79 times and average frictional resistance was calculated. Each sliding test was conducted with the same bracket, and different 0.018” stainless steel arch wire segments and 0.010” ligatures.

Fig. 1: An acrylic structure adapted to the INSTRON machine fixed the Upper right first bicuspid bracket, arch wire and ligature combination for the sliding test.

Validation of FEA

Upper right first bicuspid preadjusted conventional stainless steel brackets, round stainless steel arch wires and stainless steel ligatures were measured using a stereoscope(Nikon) with 8X and 80X magnification and a tolerance of }5 mm, assisted by image analysis software (NIS 3.1 Element, Nikon). A computeraided design (CAD) model of the bracket was constructed with microscopic measurements using the software Solid Edge 18 (Table 1, Fig. 2). Surface roughness of the slot and the arch wire was measured with a microscope (Eclipse X20 LV100) and average roughness between the observed peaks and valleys on the surface of the materials was calculated.

Fig. 2: Upper right first bicuspid bracket CAD designs. (A) Conventional bracket, (B) Passive selfligating (C) Active selfligating.

Frictional resistance was studied by FEA (ALGOR 16) in a simulation that applied the mean MSFR obtained in the experimental phase to the base of the conventional bracket slot with a 0.018” arch wire. The force distribution applied on the surface of the slot of the bracket was calculated as the weighted force on the area of influence (Fig. 3). The finite element analysis was validated by comparing the frictional resistance from the experimental method and the FEA with 95% reliability by Z test.

Fig. 3: Frictional force distribution in conventional bracket slot FEA approach.

Modeling and FEA simulation

CAD models of the following upper right first bicuspid brackets were constructed using Solid Edge V18 software, which used 4352, 4521 and 4535 tetragonal elements for (Fig.2 A, B and C): conventional Mini diamond (0.022” x 0.028”), 3MX Damon (0.022” x 0.027”) and In Ovation “R” (0.022” x 0.028”), respectively. In addition, CAD models of stainless steel, NickelTitanium (NiTi), betatitanium (TMA) and Sentalloy arch wires in 0.018”, 0.019” x 0.025”and 0.020” x 0.020” were constructed.

Surface roughness of the base of the slot was measured using a microscope (Nikon Eclipse100LV), assisted by software (NIS3.1ELEMENT3D reconstruction). Average roughness was 0.03 mm for three different types of brackets and it was incorporated into the CAD model of each bracket. Sliding simulations using different combinations of brackets and arch wires were performed using the ALGOR16 finite element analysis software. A 3N force was applied to the base of the slot in all simulations. A vertical force represented the ligation force. The normal force applied in each simulation was calculated by the following equations15: For conventional Mini diamond brackets:

![]()

where FN is the normal force applied by the ligature to the archwire (and also the base of the slot), i.e. the force produced by the ligature against the slot; E is the modulus of elasticity of the ligature; I is the moment of inertia of the cross section of the ligature; l is the length between the free ends of the ligature, and δ is the archwire displacement exerted on the ligature. For InOvation R brackets the relationship between force and displacement of the binding was15:

![]()

Damon brackets, the normal force was not calculated since there is no metal spring clip or ligature, so that normal force was not taken into account during sliding with this type of bracket.

To simulate bracket adhesion to the tooth surface, displacement restriction of the bracket base was applied. Frictional resistance was expressed by stress force (N/mm2) in each simulation by the Von Mises criteria.

RESULTS

Experimental phase

The in vitro average frictional resistance of the 79 sliding repetitions was 2.41 } 0.26 N (p = 0.05) with 95% CI (2.35 2.47 N). The results showed high consistency during the experiments.

Validation of FEA

The highest concentration of frictional force was located in the central area of the bottom of the conventional bracket slot, whereas at the edges of the slot, the forces were almost nonexistent (Fig. 3). The weighted sum of the forces according to their area of influence resulted in a force of 2.43 N. This FEA simulation was conducted once, in order to validate the approach with respect to experimental frictional sliding stage. Comparison of results obtained from the in vitro experiments and the FEA simulation showed that there is no statistical difference (p = 0.7493> 0.05) between the two methods. Hence, the FEA method is validated to study frictional forces in different combinations of brackets and archwires.

Modeling and FEA simulation

Each combination of brackets and archwires produced characteristic patterns of stress distribution at the bottom of the slot. Fig. 4 shows stress distribution for the three brackets in combination with the three different types of steel archwire. In a conventional bracket, a 0.018” archwire the stress was produced with an arrangement in the same line with a maximum concentration in the center of the line (Fig 4A). Conversely, 0.020 x 0.020“ and 0.019 x 0.025” wires produced stress distribution across the width of the slot. In this case, the contact surfaces are on two planes, and stresses are thus distributed more evenly.

Fig. 4: Stress distribution for the three types of brackets in combination with the three different types of stainless steel archwire by FEA approach. 4A. Conventional bracket / 0.018” archwire. 4B. Passive selfligating/ 0.019” x 0.025” archwire. 4C. Active selfligating/ 0.020” x 0.020” archwire.

Table 2 shows consolidated maximum stress for each bracketarchwire combination. The DAMON 3 MX bracket was found to produce the least stress in all combinations, followed by the conventional bracket and the InOvation R bracket, which produced the greatest stress. With respect to the size of the archwires, least stress occurred with the 0.018” archwires, followed in quantity by the 0.019 x 0.025” archwires, while maximum stress occurred with the 0.020” x 0.020” archwires. However, the In Ovation R bracket with 0020” x 0020” wires showed less stress than with the 0019” x 0025” archwires (Fig.4B, 4C). Normal forces were only calculated for conventional and In Ovation R brackets. The highest normal force was 1.53 N for the 0.018” archwire, 4.85 N for the 0.020” x 0.020” archwire and 8.18 N for the 0.019” x 0.025” archwire. For the In Ovation R bracket,the only combination that activated the spring clip was with 0.019” x 0.025” archwire, in which the normal force was 0.14 N.

Table 2: Results in N/mm2 of the FEA sliding simulations.

DISCUSSION

Testing frictional resistance in orthodontic systems in in vitro studies depends directly on different factors such as the alloy, surface texture, bracket type, size and geometry of the archwire4,14. Other factors, including the type of bracket ligating system and the critical angle between the archwire and the slot, have also been discussed16-18. However, in these studies it is difficult to control such variables under the same conditions for each experiment. In addition, specific characteristics of the biological environment of the mouth are difficult to repli cate1,3,19,20. In contrast, finite elements analysis (FEA) allows some of the variables related to frictional resistance (surface, force, angulation, bracket bonding strength) to be controlled more precisely in a simulation model, enabling inferences to be drawn regarding how this phenomenon occurs. In this study, the use of FEA was validated for the analysis of frictional resistance. The results of the 79 preliminary sliding experiments performed in an INSTRON machine showed that mean maximum static frictional resistance (MSFR) was comparable to the same results in the FEA analysis. FEA was thus used as a valid alternative to study frictional resistance with different types of bracket and archwires. Kojima et al. conducted a study in 2006 21with the aim of assessing the combined effect of friction and stiffness of an archwire applied in the movement of a canine during sliding mechanics. In this study, a 5 mm retraction of canines was simulated by FEA. The authors used conventional brackets and square stainless steel archwires (0.012” to 0.020”), assuming that the archwire and the slot had the same size and there was no clearance between them. They report that there is a reduction in the net force applied to the canine with increasing coefficients of friction. Nonetheless, the simulation showed a distribution of stress, rather than forces, and it is thus difficult to estimate the net force acting on each part of the bracket archwire system21. Other than the fact that the authors did not validate the FEA, the results provide significant insights of the frictional events occuring during orthodontic movement. In this study, the normal force, mechanical properties of the materials and average surface roughness of the archwire and bracket were calculated for stainless steel, because all of the materials have the same composition. Although there is not a friction coefficient, the calculation and use of these properties allowed deductions to be made regarding their effects in each simulation, according to the stress undergone by the surfaces. The results of this study show that in conventional brackets there is increased frictional resistance in the rectangular archwire compared to the square archwire. It may be attributable to the larger contact area between the bottom of the slot and the 0.020 x 0.020” archwire compared to the 0.019” x 0.025” archwire.

This indicates that there is greater normal force on the 0.019 x 0.025”archwire compared to the 0.020” x 0.020”archwire, which means that for simulations with FEA, the bracketarchwire contact surface is more important to MSFR than the normal force itself. The normal force applied by the ligature is a subjective variable that depends on each clinician and is therefore uncontrollable21. Clearly, the value of the stress was not affected by the mechanical properties introduced to the model (Young modulus, shear modulus and Poisson modulus), but rather by the contact surface geometry and the applied force. The interpretation of this behavior is that the stress is the intensive form of the applied force. The passive selfligating bracket showed the same behavior as conventional brackets with respect to the dimensions of the archwire.

Greater bracketarchwire surface contact produced higher MSFR values. Due to the fact that in the simulations with passive selfligating bracket there was no normal force to press the archwire against the bottom of the bracket, roughness was a constant and the properties of the materials did not influence this behavior. Hence, MSFR was the result of the contact surface between the bottom of the slot and the archwire. Active selfligating brackets had the lowest MSFR with the 0.018” archwire; from the stand point of shear stress, frictional force is only a function of the applied force as the same as the roughness and geometry of the slot and wire. In contrast, MSFR produced with the 0.019” x 0.025” archwire was greater than that produced with the 0.020” x 0.020” archwire. This difference was due to the normal force exerted by the spring clip. Spring clips in active selfligating brackets are activated with archwire sizes≥ 0.025”. Thus, when a 0.020” x 0.020” archwire is placed into the slot, it does not activate the spring clip and consequently there is no normal force present. On the other hand, the 0.019” x 0.025” archwire activates the spring clip and the normal force exerted is similar to that produced by the ligature, resulting in an increase in frictional resistance. From the simulations performed in this study, it can be inferred that the increase in MSFR was determined more by the normal force expressed by the spring clip than by the contact area between the archwire and the slot. Several in vitro studies 5,7,8 are consistent with this study, in which the passive selfligating brackets generated lower frictional resistance than conventional brackets used with small, round archwires, and even for larger archwires.18,22,23

With respect to active selfligating brackets, this study found that they have a higher frictional resistance than conventional brackets in all combinations, because the active selfligating bracket has greater contact area than the conventional bracket. Several studies 1,9,10, however, report lower frictional resistance of active selfligating brackets than conventional brackets, which may be because these studies included other variables such as roughness24, which was a constant in our study. In this study, the mechanical properties of the materials did not affect frictional resistance. The result of the FEA simulations, according to several in vitro studies23-28, showed active ligating brackets have higher frictional resistance than passive selfligating brackets due to the absence of normal force. Nonetheless, studies by Shivapuja and Berger5 compared the same types of brackets and reported no difference.

Several studies have analyzed how secondorder angulation and torque affect frictional resistance. Thorstenson and Kusy29 found that shear strength at any angle is lower for selfligating brackets than for conventional brackets. Another study13, however, noted that when secondorder angles were incorpo rated, active ligating brackets did not reduce frictional resistance when compared to conventional brackets. Unlike these studies, ours did not include angulation or torque as a variables to be analyzed, but future studies may include them, using FEA and evaluate their influence on frictional resistance.

CONCLUSIONS

According to the FEA, passive selfligating brackets have less frictional resistance than conventional and active selfligating brackets. Active selfligating brackets have the highest frictional resistance, determined by the greater contact area and the spring clip. However, regardless of bracket type, a greater contact area between slot and archwire increases frictional resistance. Passive selfligating brackets could be used to improve efficiency in initial phases of orthodontic treatment.

ACKNOWLEDGMENTS

We would like to thank biomedical engineer Sebastian Torres (Antioquia School of engineering CES University, Medellin, Colombia), for his scientific and academic support during the simulation analyses.

The authors report no conflict of interests.

1. Hain M, Dhopatkar A, Rock P. A comparison of different ligation methods on friction. Am J Orthod Dentofacial Orthop 2006;130:666-670. [ Links ]

2. Gandini P, Orsi L, Bertoncini C, Massironi S, Franchi L. In vitro frictional forces generated by three different ligation methods. Angle Orthod 2008;78:917-921. [ Links ]

3. Rinchuse DJ, Miles PG. Selfligating brackets: Present and future. Am J Orthod Dentofacial Orthop 2007;132:216-222. [ Links ]

4. Ehsani S, Mandich MA, El Bialy TH, Flores Mir C. Frictional resistance in selfligating orthodontic brackets and conventionally ligated brackets. Angle Orthod 2009; 79:592-601. [ Links ]

5. Shivapuja PK, Berger J. A comparative study of conventional ligation and selfligation bracket systems. Am J Orthod Dentofacial Orthop 1994;106:472-480. [ Links ]

6. Cacciafesta V, Sfondrini MF, Ricciardi A, Scribante A, Klersy C, Auricchio F. Evaluation of friction of stainless steel and esthetic selfligating brackets in various bracketarchwire combinations. Am J Orthod Dentofacial Orthop 2003; 124:395-402. [ Links ]

7. Griffiths HS, Sherriff M, Ireland AJ. Resistance to sliding with 3 types of elastomeric modules. Am J Orthod Dentofacial Orthop 2005;127:670-675. [ Links ]

8. Kim TK, Kim KD, Baek SH. Comparison of friction0al forces during the initial leveling stage in various combina tions of selfligating brackets and archwires with a customdesigned typodont system. Am J Orthod Dentofacial Orthop 2008;133:187e1524. [ Links ]

9. Voudouris JC. Interactive edgewise mechanisms: form and function comparison with conventional edgewise brackets. Am J Orthod Dentofacial Orthop 1997;111:119-140. [ Links ]

10. Tecco S, Festa F, Caputi S, Traini T, Di Iorio D, D’Attilio M. Friction of conventional and selfligating brackets using a 10 bracket model. Angle Orthod 2005;75:1041-1045.

11. Franchi L, Baccetti T, Camporesi M, Barbato E. Forces released during sliding mechanics with passive selfligating brackets or nonconventional elastomeric ligatures. Am J Orthod Dentofacial Orthop 2008;133:87-90. [ Links ]

12. Kahlon S, Rinchuse D, Robison J, Close JM. Invitro evaluation of frictional resistance with 5 ligation methods and Gianellytype working wires. Am J Orthod Dentofacial Orthop 2010;138:67-71. [ Links ]

13. Redlich M, Mayer Y, Harari D, Lewinstein I. In vitro study of frictional forces during sliding mechanics of ‘‘reducedfriction’’ brackets. Am J Orthod Dentofacial Orthop 2003; 124:69-73.

14. Krishnan V. Mechanical properties and surface characteristics of three archwire alloys. Angle Orthod 2004;74: 825-831. [ Links ]

15. Hibbeler R. Mechanics of materials, 4th Ed. Boston USA: Pearson 1998; 607-608. [ Links ]

16. Kusy RP, Whitley JQ. Frictional resistances of metallined ceramic brackets vs Conventional stainless steel brackets and development of 3D friction maps. Angle Orthod 2001; 71: 364-374. [ Links ]

17. Kapur R, Sihna PK, Nanda RS. Comparison of frictional resistance in titanium and stainless steel brackets. Am J Orthod 1999; 116: 271-274. [ Links ]

18. Kusy R.P, Whitley J. Influence of archwire and bracket dimensions on sliding mechanics: derivations and determinations of the critical contact angles for binding. Eur J Orthod 1999;21:199-208. [ Links ]

19. Frank CA, Nikolai RJ. A comparative study of frictional resistance between orthodontic bracket and archwire. Am J Orthod 1980;78:593-609. [ Links ]

20. Scott P, Di Biase A, Sheriff M, Coboume MT. Alignment efficiency of Damon 3 selfligating and conventional orthodontic bracket systems: A randomized clinical trial. Am J Orthod Dentofacial Orthop 2008;134:470. E18. [ Links ]

21. Kojima Y, Fukui H, Miyajima K. The effects of friction and flexural rigidity of the archwire on canine movement in sliding mechanics: A numerical simulation with a 3dimen sional finite element method. Am J Orthod Dentofacial Orthop 2006;130:275.e1275. e10. [ Links ]

22. Kusy RP, Whitley JQ, de Araujo G. Comparisons of surface roughness and sliding resistances of 6 titaniumbased or TMA type archwires. Am J Orthod Dentofacial Orthop 2004;126:589-603. [ Links ]

23. Sims AP, Waters NE, Birnie DJ. A comparison of the forces required to produce tooth movement ex vivo through three types of preadjusted brackets when subjected to determined tip or torque values. Am J Orthod 1994;21:367-373. [ Links ]

24. Kusy RP, Whitley J Q. Effects of surface roughness on the coefficients of friction in model orthodontic systems. J Biomech 1990;23:913-925. [ Links ]

25. Angolkar PV, Kapila S, Duncanson MG, Nanda RS. Evaluation of friction between ceramic brackets and orthodontic wires of four alloys. Am J Orthod Dentofacial Orthop1990;98:499-506. [ Links ]

26. Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofacial Orthop 1989;96:397-404. [ Links ]

27. Saunders CR, Kusy RP. Surface topography and frictional characteristics of ceramic brackets Am J Orthod Dentofacial Orthop 1994;106:76-87. [ Links ]

28. Oliver C, Daskalogiannakis J, Tompson B. Archwire depth is a significant parameter in the frictional resistance of active and interactive, but not passive, selfligating brackets. Angle Orthod 2011;81:1036-1044. [ Links ]

29. Thorstenson GA, Kusy RP. Resistance to sliding of selfligating brackets versus conventional stainless steel twin brackets with second order angulation in the dry and wet (saliva) states. Am J Orthod Dentofacial Orthop 2001;120: 361-370. [ Links ]