Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Acta Odontológica Latinoamericana

On-line version ISSN 1852-4834

Acta odontol. latinoam. vol.31 no.3 Buenos Aires Dec. 2018

ORIGINAL ARTICLE

Sliding resistance of rectangular vs. beveled archwires in two self-ligating brackets: a finite element study

Resistencia al deslizamiento entre arcos rectangulares y biselados en brackets de autoligado: estudio de elementos finitos

Armando J. Iriarte1, Susana Ortiz1, Katerine Cubides-Flechas1, Catalina Olaya1, Gustavo Jaimes-Monroy1,2,3

1 Universidad Antonio Nariño, Facultad de Odontología, Postgrado de Ortodoncia, Bogotá Colombia.

2 Universidad Antonio Nariño, Facultad de Odontología, Grupo Investigación en Salud Oral. Bogotá, Colombia.

3 Universidad Nacional Abierta y a Distancia. Escuela de Ciencias de la Salud, Bogotá, Colombia.

ABSTRACT

The aim of this study was to use a 3-D finite element method (FEM) to compare the sliding resistance of 0.019"x0.025" stainless steel conventional archwires versus 0.019"x0.025" stainless steel beveled archwires in active (In-Ovation® Dentsply) and passive (SmartClip®, 3M) self-ligating brackets with 0.022" x 0.028" slots. A model was designed for each kind of bracket-archwire system and the following parameters were introduced in the models: friction coefficient calculated for stainless steel bracket-wire: 0.7 pm; Poisson ratio for stainless steel wire: 0.3, and elastic module: 205 GPa for bracket and 190 GPa for archwire. Static structural analysis was applied for homogeneous, linear and isotropic properties considering contacts between wire and bracket as frictional. The results indicate that the beveled archwire generates less stress than the rectangular wire in SmartClip® and In-Ovation® brackets. Comparing brackets, SmartClip® generated less stress than InOvation®. It is concluded that beveled rectangular arch wires provide the advantage of reduced sliding resistance, which is better in some clinical situations to improve orthodontic mechanics.

Key words: Friction; Orthodontic brackets; Finite element analysis.

RESUMEN

El objetivo de este artículo fue comparar con el método tridimensional de elementos finitos (MEF) el comportamiento de la resistencia al deslizamiento expresado en esfuerzos de arcos de acero inoxidable 0.019"x0.025" convencionales y arcos de acero inoxidable con bisel de 0.019"x0.025" en brackets de autoligado slot 0.022" x 0.028" activo (InOvation® "R" Dentsply) y pasivo (SmartClip® 3M). Se diseñó un modelo de los brackets de autoligado In-Ovation® "R" Dentsply, SmartClip® 3My de los arcos de acero inoxidable convencionales y arcos de acero inoxidable con bisel, el análisis se calculó con el coeficiente de fricción para el bracket de acero inoxidable con el del arco de acero inoxidable: p 0.7. La relación de Poisson 0.3 para el arco de acero inoxidable.

El módulo de elasticidad del bracket: 205 GPa y del arco: 190 GPa. La aplicación del método se realizó para un análisis estructural estático con condiciones de material homogéneas, lineales e isotrópicas y con contactos de tipo fricción entre el arco y el bracket. Se observó que el arco biselado generó menos esfuerzo que el arco rectangular en el bracket SmartClip® y en el bracket In-Ovation® "R", siendo el SmartClip® en el que se generó menor esfuerzo. Se encontró que existe una ventaja en el uso de los arcos rectangulares con bisel ya que presentan menor resistencia al deslizamiento optimizando en algunas situaciones clínicas las mecánicas ortodónticas.

Palabras clave: Fricción; Brackets; Análisis de elementos finitos.

INTRODUCTION

Resistance to sliding occurs on a continuous archwire as it slides through the bracket slot, producing frictional forces1. Frictional forces act parallel to the long axis of the archwire and are produced by normal forces at 90° to the archwire1,2.

The ligating method produces some frictional force3-6, mostly related to the normal forces required for moving teeth1.

Frictional forces are evident throughout all stages of orthodontic treatment and involve mesiodistal sliding between the archwire and the bracket1.

Twelve to sixty percent of the force applied in fixed braces is lost through friction7. This happens not only with useful sliding mechanics such as canine retraction, but also in alignment arches, where if the arch cannot slide, buccal or lingual forces may be attenuated1. Friction may also be employed to open space in cases of discrepancies in arch length1. Although most orthodontic papers published refer to evaluation of friction, in reality they evaluate resistance to sliding8. Frictional resistance reduces the efficiency of orthodontic treatment due to the loss in total force applied2,9,10. Finite element analysis has shown that 60% to 80% of orthodontic force applied is lost during retraction due to the sliding mechanics of a canine along a rectangular archwire11.

It is important to eliminate or minimize frictional forces when planning orthodontic tooth movement12,13. During orthodontic treatment, frictional forces should be kept to a minimum in order to enable application of lower levels of force and optimal biological response for efficient dental movement14-16. In orthodontics, friction occurs between the bracket, the archwire and ligature 17-20. Resulting frictional resistance reduces the efficacy of orthodontic treatment due to the total loss of the force applied (21% to 60%)21.

Several studies have shown a significant reduction in friction by using self-ligating brackets, with a reduction in time required to move teeth6,22-25. Stefanos et al. (2010) performed a comparative study of friction with passive and active brackets, and found that passive self-ligating brackets have less static and kinetic friction than active self-ligating brackets when combined with 0.019"x 0.025" stainless steel archwires 3. Huang et al. (2012) showed that passive self-ligating brackets are associated to lower static or kinetic friction than conventional brackets20.

Shumacher et al. (1998) evaluated frictional forces when using conventional and beveled rectangular archwires, concluding that among the numerous parameters that affect the degree of friction exerted, archwire beveling has a positive, though secondary effect26. Comparison of all measurements revealed that archwires with slightly beveled edges combined with steel ligature should be preferred to an archwire without beveled edges, because a moderate bevel improves friction by approximately 10%26.

To optimize sliding mechanics, rectangular archwire cross section has been modified by beveling the edges26. The 3M® company has developed beveled archwires called hybrids for use with SmartClip® 3M self-ligating appliance, but they have not yet been tested in other self-ligating brands. Therefore, we propose a study to evaluate the benefits that those archwires may provide to other types of brackets. The aim of this study is to use the 3dimensional finite element method (FEM) to compare resistance to sliding expressed as stress of 0.019" x 0.025" conventional stainless steel wires and 0.019" x 0.025" stainless steel wires with beveled edges in active (In-Ovation® "R" Dentsply) and passive (SmartClip® 3M) self-ligating brackets with 0.022" x 0.028" slots .

MATERIALS AND METHODS

A numerical simulation was performed using the 3dimensional finite element method (FEM). Models were designed of the active (In-Ovation® "R" Dentsply) and passive (SmartClip® 3M) self-ligating brackets with 0.022" x 0.028" slots and of the conventional 0.019" x 0.025" stainless steel archwires and 0.019" x 0.025" stainless steel archwires with beveled edges, the latter using the measurements of the 3M patented hybrid archwire. For the analysis, the friction coefficient for the stainless steel bracket with the stainless steel archwire was calculated as p=0.727, Poisson ratio was 0.3 for the stainless steel archwire28,29 and modulus of elasticity was 205 GPa for the bracket and 190 GPa for the archwire10. The active bracket ligating system uses a latch and the passive system uses a clip. Slot size is the same for both brackets. The method presented herein was applied for a static structural analysis with homogeneous, lineal, isotropic material conditions and friction-type contacts between archwire and bracket.

The 3D model was designed according to the technical specifications of each manufacturer. Geometry, mesh and boundary conditions were defined in each model and developed on Autodesk Inventor® software (Fig. 1).

Fig. 1: Designs. (A) 0.019”x0.025” rectangular steel archwire, (B) 0.019”x0.025” beveled rectangular steel archwire, (C) Passive selfligating bracket, (D) Active selfligating bracket.

The Autodesk Inventor® 3D geometric model was exported and imported in Ansys Workbench®. When the model was acquired by the FEM software, it was meshed and contact area refinement was employed (Table 1) in order to achieve a mesh that would enable the friction problem to be resolved.

Table 1: Number of nodes and elements on which geometry was meshed.

Static structural analysis was performed to determine the difference in behavior with regard to friction between a rectangular archwire and an archwire with beveled edges for both types of brackets under the same working conditions (Tables 2-3, Fig. 2).

Table 2: Working conditions.

Table 3: Material properties.

Fig. 2: Boundary conditions. (A) Restriction of movement, (B) Application of sliding.

RESULTS

General strain

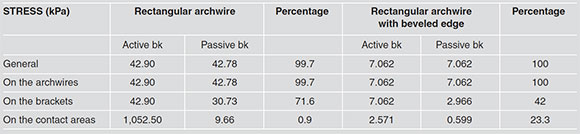

General results are presented in kilopascal (kPa). For the passive bracket, maximum stress was 42.78 kPa with rectangular archwire and 7.062 kPa with beveled archwire. For the active bracket, stress was 42.90 kPa with rectangular and 7.062 kPa with beveled archwire (Fig. 3,Table 4).

Fig. 3: Results of strains of the different models in Mpa. (A) Rectangular archwirePassive bracket, (B) Rectangular archwireActive bracket, (C) Beveled archwirePassive bracket, (D) Beveled archwireactive bracket.

Table 4 .

Strain on archwires

Results for strain test on archwires are presented in kilopascal (kPa). For the rectangular archwire, maximum stress was 42.78 kPa with passive bracket and 42.90 kPa with active bracket. For the beveled archwire, maximum strain was 7.062 kPa with passive bracket and 7.062 kPa with active bracket (Fig. 4,Tabla 4).

Fig. 4: Results of strains on wires in Mpa. (A) Rectangular wire, (B) Rectangular wire (C) Beveled wire (D) Beveled wire.

Stress on brackets

Results are presented in kilopascals (kPa). For sliding in passive bracket, maximum stress was 30.73 kPa for rectangular archwire and 2.966 kPa for beveled archwire. For active bracket it was 42.90 kPa for rectangular archwire and 7.062 kPa for beveled archwire (Fig. 5,Table 4).

Fig. 5: Results of strains on brackets in Mpa. (A) Passive bracket, (B) Active bracket, (C) Passive bracket, (D) Active bracket.

Strain in bracket contact areas

Results in contact areas are presented in kilopascals (kPa). Maximum value for passive bracket was 9.66 kPa with rectangular archwire and 0.599 kPa with beveled archwire. For active bracket, values were 1052.50 kPa with rectangular archwire and 2.571 kPa with beveled archwire (Fig. 6,Table 4).

Fig. 6: Results of strains for the contact areas (areas that generate friction) for each model in MPa. (A) Rectangular wirePassive bracket, (B) Rectangular wireActive bracket, (C) Beveled wirePassive bracket, (D) Beveled wireActive bracket.

Stress was calculated for archwires, brackets and areas in order to determine the proportional values, assigning 100% to the highest value. Table 5 shows the results of resistance to stress for the following conditions: general, on the archwires, on the brackets and on the contact areas, for rectangular archwire and beveled archwire. The results are relevant, considering that in this model, beveled archwire with both types of brackets has the lowest stress for all conditions assessed.

Table 5.

The proportion of strain for variability between the passive bracket and the two kinds of archwire was calculated in the same way. For general results, beveled wire obtained 16.5% of the stress generated by the rectangular archwire. For results on archwire, beveled archwire obtained 16.5% of the stress generated by the rectangular archwire. For the results on bracket, the beveled archwire obtained 9.7% of the stress generated by the rectangular archwire. In the results on bracket contact area, beveled archwire obtained 6.2% of the stress generated by the rectangular archwire (Table 5). Percentages of variability were calculated for rectangular archwire with the two kinds of bracket.

For general results, passive bracket stress was 99.7% of the stress generated in active bracket. For archwire, passive bracket obtained 99.7% of the stress generated in the active bracket. For bracket, passive bracket obtained 71.6% of the stress generated in the active bracket. For bracket contact area, passive bracket obtained 0.9% of the stress generated in the active bracket (Table 4). Proportions were calculated for beveled archwire with the two kinds of bracket. For general results, active bracket obtained 100% of the stress generated in the passive bracket. For archwire, active bracket obtained 100% of the stress generated in the passive bracket. For brackets, passive bracket obtained only 42% of the stress generated in active bracket. For bracket contact area, passive bracket obtained only 23.3% of the stress generated in active bracket (Table 4).

DISCUSSION

Finite element analysis has been used by different authors to evaluate resistance to sliding10,28-30. The current study compares resistance to sliding with conventional rectangular archwires and beveled rectangular archwires in active and passive self-ligating brackets, in view of the need for information to determine whether beveled archwires improve sliding mechanics.

This study found lower resistance to sliding in active and passive brackets with the 0.019" x 0.025" beveled archwire than with the rectangular non-beveled 0.019" x 0.025" archwire. This confirms the findings of Shumacher et al., 1998, evaluating frictional forces with beveled and unbeveled rectangular archwires during canine retraction using an electronic typodont and an orthodontic measurement simulation system. They concluded that among the many parameters affecting the degree of friction exerted, archwire bevel has a positive effect26. Comparison of all measurements shows that an archwire with slightly beveled edges combined with steel ligature is preferable to an archwire without beveled edges, since moderate bevel reduces friction by approximately 10%26. Current evidence suggests that further research is needed regarding these outcomes when archwires with beveled edges are used on brackets with different features from those indicated by sellers.

The current study showed more resistance to sliding in active brackets than in passive brackets when sliding rectangular archwire, in agreement with Stefanos et al. (2010), who found that passive self-ligating brackets have lower static and kinetic frictional forces than active self-ligating brackets when combined with 0.019" x 0.025" stainless steel archwire3.

The results of the current study agree with Huang et al. (2012), who showed that passive self-ligating brackets are associated to lower static or kinetic frictional force than conventional brackets20. Gómez et al. (2016) compared frictional resistance between passive and active self-ligating brackets using finite element analysis and in vitro assays.

They found that passive self-ligating brackets showed lowest resistance to sliding, followed by conventional brackets and active brackets. They determined that a greater contact area between the slot, the archwire and the clip increases resistance to sliding10. The results in the paper by Gómez are consistent with the finding in the current finite element model, where there was lower resistance to sliding in passive self-ligating brackets than in active self-ligating brackets when sliding a 0.019" x 0.025" rectangular archwire. In addition, it was established that when stress isare measured in the model, both in brackets and archwires, a larger contact area between the slot and the archwire increases resistance to sliding.

The stress generated for this finite element model in the SmartClip® bracket showed that the beveled archwire had lower resistance to sliding than the rectangular archwire.

The stress generated for this finite element model in the In-Ovation® "R" bracket showed that the beveled archwire had lower resistance to sliding than the rectangular archwire.

Analysis of the stress generated for each bracket type in this finite elements model shows that there is lower resistance to sliding in passive self-ligating brackets than in active self-ligating brackets for 0.019" x 0.025" rectangular archwire.

It is recommended to use in vitro and in vivo studies to compare the results of this model and determine its clinical application because resistance to sliding is determined by many variables such as biological parameters (saliva, plaque, tissue response, etc.), mechanical characteristics (angle, degree of malocclusion, etc.) and physical and chemical properties of the material.

ACKNOWLEDGMENTS

The authors thank José Alejandro Guerrero Vargas, engineer, from National University of Colombia, for his work on the construction of the finite elements model.

FUNDING

None

CORRESPONDENCE

Dr.Gustavo Jaimes Monroy

Universidad Antonio Nariño, Sede Circunvalar,

Carrera 3 Este # 47 A - 15, Bloque 5 Bogotá Colombia

tavojaimes@uan.edu.co

1. Burstone C, Choy K. The Biomechanical Foundation of Clinical Orthodontics. 1a ed. Chicago, Berlin, Tokyo, London, Paris, Milan, Barcelona, Istanbul, Moscow, New Delhi, Prague, Sao Paulo, Seoul, and Warsaw: Quintessence Publishing Co, Inc; 2015; P. 608. [ Links ]

2. Rossouw PE, Kamelchuk LS, Kusy RP. A fundamental review of variables associated with low velocity frictional dynamics. Semin Orthod. 2003;9:223-235. [ Links ]

3. Stefanos S, Secchi AG, Coby G Tanna N, Mante FK. Friction between various self-ligating brackets and archwire couples during sliding mechanics. Am J Orthod Dentofac Orthop 2010; 1379:463-467. [ Links ]

4. Cacciafesta V, Sfondrini F, Ricciardi A. Evaluation of friction of stainless steel and esthetic self-ligating brackets in various bracket-archwire combinations. Am J Orthod Dentofac Orthop 2003; 124:395-402. [ Links ]

5. Gandini P, Orsi L, Bertoncini C, Massironi S, et al. In vitro frictional forces generated by three different ligation methods. Angle Orthod 2008; 78:917-921. [ Links ]

6. Rozzi M, Mucedero M, Franchi L. Friction in a hybrid system. An in vitro study. Roma Italia: Oral & implantology 2010; p. 2-8. [ Links ]

7. Kusy RP, Whitley JQ. Friction between different wire-bracket configurations and materials. Semin Orthod 1997; 3:166-177. [ Links ]

8. Ehsani S, Mandich MA, El-Bialy TH, Flores-Mir C. Frictional resistance in self-ligating orthodontic brackets and conventionally ligated brackets a systematic review. Angle Orthod 2009; 79:592-601. [ Links ]

9. Kusy RP. Influence of angulation on the resistance to sliding in fixed appliances. Am J Orthod Dentofacial Orthop 1999; 115:39-51. [ Links ]

10. Gômez SL, Montoya Y, Garcia NL, Virgen AL, Botero JE. Comparison of frictional resistance among conventional , active and passive self-ligating brackets with different combinations of arch wires : a finite elements study. Acta Odontol Latinoam 2016; 29:130-136. [ Links ]

11. Kojima Y, Fukui H. Numerical simulation of canine retraction by sliding mechanics. Am J Orthod Dentofac Orthop 2005; 127:542-551. [ Links ]

12. Drescher D, Bourauel C, Schumacher HA. Frictional forces between bracket and arch wire. Am J Orthod Dentofac Orthop 1989; 96:397-404. [ Links ]

13. Frank CA, Nikolai RJ. A comparative study of frictional resistances between orthodontic bracket and arch wire. Am J Orthod 1980; 78:593-609. [ Links ]

14. Kapila S, Angolkar P V, Duncanson MG, Nanda RS. Evaluation of friction between edgewise stainless steel brackets and orthodontic wires of four alloys. Am J Orthod Dentofac Orthop 1990; 98:117-126. [ Links ]

15. Ogata RH, Nanda RS, Duncanson JMG, Sinha PK, Currier GF. Frictional resistances in stainless steel bracket-wire combinations with effects of vertical defections. Am J Orthod Dentofac Orthop 1996; 109:535-542. [ Links ]

16. Park JH, Lee YK, Lim BS, Kim CW. Frictional forces between lingual brackets and archwires measured by a friction tester. Angle Orthod 2004; 74:816-824. [ Links ]

17. Bednar JR, Gruendeman GW, Sandrik JL. A comparative study of frictional forces between orthodontic brackets and arch wires. Am J Orthod Dentofac Orthop 1991; 100:513-522. [ Links ]

18. Edwards GD, Davies EH, Jones SP. The ex vivo effect of ligation technique on the static frictional resistance of stainless steel brackets and archwires. Br J Orthod 1995; 22:145-153. [ Links ]

19. Wichelhaus A, Geserick M, Hibst R, Sander FG. The effect of surface treatment and clinical use on friction in NiTi orthodontic wires. Dent Mater 2005; 21:938-945. [ Links ]

20. Huang TH, Luk HS, Hsu YC, Kao CT. An in vitro comparison of the frictional forces between archwires and self-ligating brackets of passive and active types. Eur J Orthod 2012; 34:625-632. [ Links ]

21. Hain M, Dhopatkar A, Rock P. A comparison of different ligation methods on friction. Am J Orthod Dentofac Orthop 2006; 130:666-670. [ Links ]

22. Pizzoni L, Ravnholt G, Melsen B. Frictional forces related to self-ligating brackets. Eur J Orthod 1998; 20:283-291. [ Links ]

23. Thomas S, Sherriff M, Birnie D. A comparative in vitro study of the frictional characteristics of two types of self-ligating brackets and two types of pre-adjusted edgewise brackets tied with elastomeric ligatures. Eur J Orthod 1998; 20:589-596. [ Links ]

24. Shivapuja PK, Berger J. A comparative study of conventional ligation and self-ligation bracket systems. Am J Orthod Dentofac Orthop 1994; 106:472-480. [ Links ]

25. Kahlon S, Rinchuse D, Robison JM, Close JM. In-vitro evaluation of frictional resistance with 5 ligation methods and Gianelly-type working wires. Am J Orthod Dentofac Orthop 2010; 138:67-71. [ Links ]

26. Schumacher HA, Bourauel C, Drescher D. Frictional Forces when Rectangular Guiding Arches with Varying Edge Bevel Are Employed . J Orofac Orthop 1998; 59:139-149. [ Links ]

27. Serway RA, Kirkpatrick LD. Physics for Scientists and Engineers with Modern Physics. Vol. 26, The Physics Teacher 1988; p. 121. [ Links ]

28. Kojima Y, Fukui H, Miyajima K. The effects of friction and flexural rigidity of the archwire on canine movement in sliding mechanics: A numerical simulation with a 3dimensional finite element method. Am J Orthod Dentofac Orthop 2006; 130:1-10. [ Links ]

29. Kojima Y, Fukui H. Numeric simulations of en-masse space closure with sliding mechanics. Am J Orthod Dentofac Orthop 2010; 138:702.e1-702.e6. [ Links ]

30. Hamanaka R, Yamaoka S, Anh TN, Tominaga JY, Koga Y, Yoshida N. Numeric simulation model for long-term orthodontic tooth movement with contact boundary conditions using the finite element method. Am J Orthod Dentofacial Orthop 2017; 152:601-612. [ Links ]