INTRODUCTION

Science and technology are increasingly investing in implant dentistry, which is one of the main specialties requiring innovative materials 1 . One of these materials is PEEK (polyether-ether-ketone), an aromatic semicrystalline polymer developed in England in the late 1970s. PEEK is a high-perfor-mance thermoplastic material being researched in dentistry 2-5 .

PEEK has been considered for use in restorative procedures due to its mechanical properties 6 . In oral rehabilitation, its viability has been studied mainly for prostheses and dental implants. In Implantology specifically, it is studied as a potential altemative to titanium and zirconia, considering its biocompatibility and physical properties such as elasticity, resistance and radiolucency 7-9 .

PEEK has high resilience, resistance to fracture and corrosion and shock absorption, and low transmission of forces to the adjacent bone 10 , which can prevent abutment screw fractures, transmission of occlusal overloads to the marginal bone around dental implants, and bone loss 10 .

PEEK has an elastic modulus similar to that of bone, so it can absorb mechanical shocks. Prosthetic abutments and dental implants made from PEEK can therefore absorb and foster dissipation of masticatory loads to the peri-implant bone, thereby preventing implant failures 10 . Its main disadvantages are that it is bioinert, which may be a problem for osseointegration, and susceptible to stress deformation 9-10 . In thermal cycling with artificial saliva, PEEK has low retention in prostheses, especially at very acidic or very alkaline pH values 11-12 . There are few randomized controlled clinical studies to ensure effectiveness in its clinical use 9-10 .

Passive fit is one of the most important prerequisites for maintaining the implant-bone interface. To achieve a passive fit or stress-free framework, the framework should theoretically not induce stress on the implant components or surrounding bone in absence of external load application 13 . However, according to the available literature, it is practically impossible to achieve completely passive fit 13 . Prosthetic complications such as loosening or fracture of the prosthetic abutment screw, infrastructure and ceramic covering have been documented and may be related to poor fit of the framework 13 . In bone tissue, complications such as infections, oronasal communication or peri-implantitis are quite rare 14 .

In implant-supported bars, there is a direct relationship between the amount of deformation and the force of occlusion, while there is an inverse relationship with the modulus of elasticity of the framework material of the implant-supported bar 15 . The most usual techniques for making bars for protocol-type prostheses ultimately produce heavy structures and use laboratory procedures requiring extensive execution time, fostering failures in their manufacture. In this regard, PEEK could be an altemative material. However, due to the scarce evidence and protocol-type prostheses, further studies are required. Considering as a null hypothesis that PEEK promotes fit similar to that of cobalt-chrome, which is the material traditionally used, the aim of this study was to evaluate the fit accuracy of PEEK and cobalt-chrome implant bars, after being submitted to cycling mechanics.

MATERIALS AND METHOD

Experimental design

This was an experimental in vitro study. Experimental units consisted of two implants and mini abutments seated on them, numbered as mini abutment I and mini abutment II, the latter being closest to the cantilever. The mini abutments were connected with bars that had two levels, one made of cobalt-chrome and other made of PEEK. The positioning of the implant/mini prosthetic abutment and bars was measured before and after dry mechanical cycling. As a dependent variable, there was an assessment of the mismatch between mini abutments I and II to cylinders made of Co-Cr alloy and PEEK and the counter-torque of the screws of the mini abutments after the dry mechanical cycling test.

Sample and master model preparation

Twenty solid rectangular bars were prepared, half of them (n=10) made of polyether-ether-ketone (PEEK), and the other half (n=10) of cobalt-chrome, to be used as a control group. Aluminum molds 30 mm long x 6.97 mm wide x 12.60 mm tall were made for fixing the implants. To guide the positioning of the two external hexagon implants (3.75 x 11mm) and 4.1mm platform (Neodent), a lathe was used to make perforations 3.5 mm in diameter in the aluminum mold.

The perforations were equidistant and parallel, with precision of one micrometer (1 pm), and numbered I and II. The implants were subsequently placed using a ratchet, and standardizad with torque of 60 N.cm (Fig. 1).

Fig. 1 Master die. Dimensions: 12.60 mm high x 30 mm long x 6.97 mm thick. The distance between implants I and II was 15.24 mm.

HE 4.1 mini conical abutments (Neodent, Curitiba, Brazil) were installed on the implants with a regular transmucosal height of 1 mm and torque 32N.cm, as recommended by the manufacturer. Then, proto-col-type bars were made, a PEEK-type polymeric disc (Juvora Dental Discs, Cleveleys, UK) and a wax disc (Vitazanfabrik, Bad Sackingen, Germany) were positioned on a five-axis milling machine for machining the bars (Juvora Dental Discs, Cleveleys, UK).

After installing all the implants in the master molds with their respective mini abutments, they were scanned with a 3shape scanner, and an adapted solid body protocol-type bar project 16 was executed in the Dental System 3Shape program (Fig. 2). Ten PEEK polymer bars and ten wax bars were made in the same design, as a quadrilateral figure with dimensions 30 mm long x 6.97 mm wide x 12.60 mm tall. The wax bars were subjected to the induction casting process. The passivity of all bars was tested by visual verification in their respective metallic molds. The metal bars and polymer (PEEK) bars were screwed into the mini abutments on the implants with torque of 10N.cm, as recommended by the manufacturer, and then submitted to the dry mechanical cycling test.

Mechanical cycling

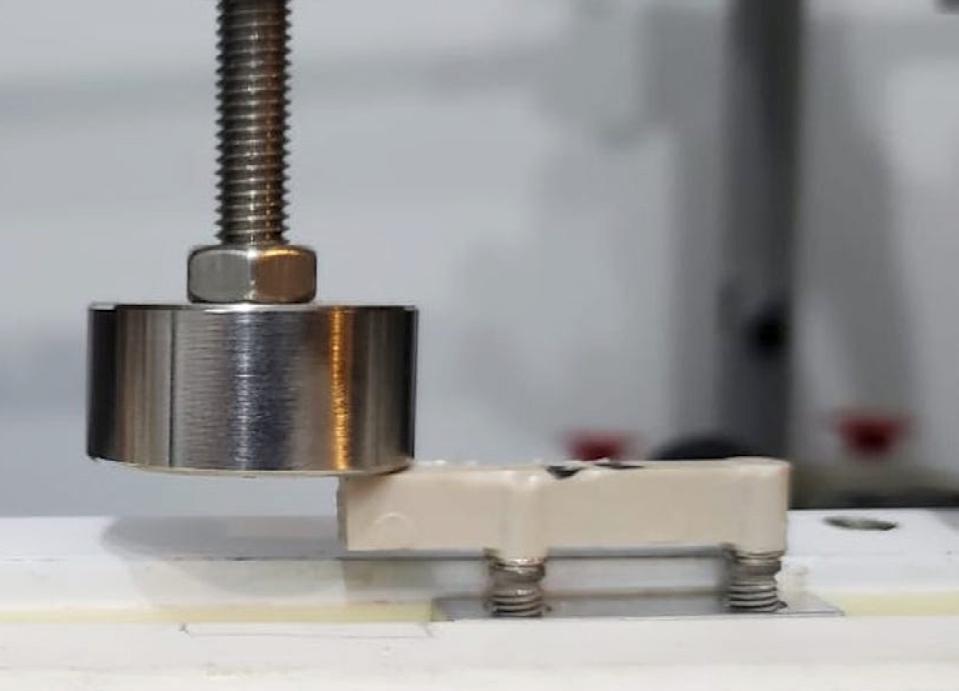

The cyclic load tests were performed in a device for mechanical cycling (MSFM, Elquip, Sao Carlos, SP, Brazil), dry and at room temperature, applying

1 million cycles on the distal cantilever of the bar in the axial direction, which simulates 50 years 17 . The cylinder drive speed and frequency were controlled by the control box that moved the pistons located inside these cylinders, compressing the specimens with a controlled force of 120N and sinusoidal loading, at a frequency of 2Hz 18 (Fig. 3).

Mini abutment/implant interface fit assessment

Before and after the mechanical cycles, the samples of the implant - mini abutment/bar set were positioned in a microhardness tester to measure the mismatch of the implant/prosthetic abutment interface and respective bars, with an increase of 100 times (Pantec, Campinas, SP - Brazil). Eight readings were performed, two on the anterior face and two on the posterior face of each implant/mini-abutment and bar set, totaling 80 measurements for each group of 10 sets. Two measurements were taken on each mini-plier, I and II, at the point where the bar was adapted to the mini-abutment. The other measurements were taken in exactly the same locations on the opposite side. Thus, four measurements were

taken on the anterior side and four on the posterior side, totaling eight measurements. An arithmetic mean of the measurements of each implant was used for analysis.

Counter-torque

Before and after the mechanical cycles, the samples of the implant - mini abutment/bar set were placed in a microhardness tester (Pantec, Campinas, SP, Brazil) to measure the mismatch of the implant/ prosthetic abutment interface and respective bars, with an increase of 100 times. A TQ 8800 digital torquemeter (LT Lutron, Taiwan) was used to measure the counter-torque of the mini abutment screws after cycling and check the abutment/implant interface mismatch. All the analyses were performed by the same operator.

Statistical analysis

Fit data were checked for adherence to normal distribution. In order to investígate the effects of bar material, implant positioning and mechanical cycling, as well as the triple and dual interactions among these three factors, the three-way analysis of variance for repeated measures was used. For multiple compari-sons, Tukey’s test was used. For counter-torque val-ues, the effects of bar material and implant position-ing, non-parametric Mann-Whitney tests were used. Statistical calculations were performed using SPSS 23 software (SPSS Inc., Chicago, IL, USA), setting the significance level at 5%.

RESULTS

Table 1 summarizes the mean values and standard deviations of the fit between the mini abutments and the protocol-type cylinder made of PEEK or cobalt-chrome, before and after mechanical cycling. Three-way analysis of variance for repeated measurements showed that there was no statistically significant interaction among the three study factors (bar material, implant positioning and mechanical cycling) (p = 0.592). No statistically significant effect was identified between the bar material and implant positioning (p = 0.321), or between implant positioning and mechanical cycling (p = 0.503). The association between bar material and mechanical cycling was statistically significant (p = 0.007).

Table 1 Means and standard deviations of the fit (pm) between the mini abutments and the cylinder of protocol-type bars made of PEEK or cobalt-chrome, before and after mechanical cycling.

|

Bar material |

Before cycling |

After cycling |

||

|---|---|---|---|---|

|

Mini abutments I |

Mini abutments II |

Mini abutments I |

Mini abutments II |

|

|

PEEK |

6.02 (0.93) |

6.32 (1.24) |

5.81 (1.48) |

5.97 (1.10) |

|

Cobalt-Chrome |

7.35 (1.04) |

7.17 (0.82) |

10.62 (5.88) |

9.17 (1.21) |

Table 2 shows the results of the statistically significant interaction. Both before and after mechanical cycling, the misfit was significantly greater with the cobalt-chrome bar than with the PEEK bar. Only cobalt-chrome resulted in greater misfit with mechanical cycling. For the PEEK bar, the misfit between the mini abutments and their cylinder was not significantly affected by mechanical cycling.

Table 2 Means and standard deviations of misfit (pm) between the cylinder of protocol-type bars made of PEEK or cobalt-chrome and the mini abutments, without considering their positioning, before and after mechanical cycling.

|

Bar material |

Before cycling* |

After cycling* |

|---|---|---|

|

PEEK |

6.17 Aa (1.08) |

5.89 Aa (1.27) |

|

Cobalt-Chrome |

7.26 Ba (0.92) |

9.89 Bb (4.20) |

The Mann-Whitney tests showed no significant difference (Table 3) in the values of counter-torque in the screws of the mini-abutments I and II with either cobalt-chrome (p = 0.257) or PEEK (p = 0.473) bars.

Table 3 Medians, means and standard deviations of the counter-torque (N.cm) of mini abutment screws, according to their positioning and the material used in making the protocol-type bar.

|

Bar material |

Mini abutment I |

Mini abutment II |

|---|---|---|

|

PEEK |

3 Aa 2.50 (1.4) |

2 Aa 1.90 (1.4) |

|

Cobalt-Chrome |

4 Aa 2.3 (5.36) |

1 Aa 0.40 (3.9) |

DISCUSSION

The search for alternative materials for implant-supported bars is justified by the concern about a possible release of metals from cobalt-chrome alloys into the bloodstream 3 . The present study sought to evalúate the properties of PEEK by comparing fit accuracy between PEEK and conventional Co-Cr bars. The findings refuted the null hypothesis because the experimental bar had lower misfit values.

The results demonstrated that the interaction between the bar’s composition material and the performance of mechanical cycling affected the marginal fit of the mini abutment. In this context, PEEK bars achieved better marginal fit before and even after mechanical cycling. This might be explained by the fact that PEEK has a lower modulus of elasticity and absorbs more tension, distributing the load on the bar more evenly 18-20 .

These findings complement existing evidence for use in dentistry, which point to aesthetic feasibility 21 , biocompatibility and elasticity 10 , with several studies suggesting optimistic results regarding physical, chemical and mechanical properties 19-21 . In the present study, the cantilever region was chosen because it is the most affected by masticatory forces, as noted in other studies 16, 23 . Room temperature was used without impact on the results since the critical temperature to modify the properties of PEEK is above 75 °C 24 .

PEEK is limited to use in healing abutments or prosthetic dental devices. Further, more complex investigations are needed, including histopathological studies investigating how to improve osseointegration, since PEEK is bioinert 9, 10-25 . However, it has been proven that osseointegration occurs in implants with PEEK 26 , and surface modification with laser, bioactive materials or chemical treatments has been proposed 27 .

The need for further research on protocol bars is confirmed by the fact that the literature is mainly related to overdentures. Corroborating the results of the present research, other studies have reported that structures made of PEEK provide better retention, and lower stress concentration or misfit than those made of Co-Cr alloy 20,28, 29 . Clinical and longer-term studies have shown good outcomes and patient satisfaction with PEEK 30 . Despite the lack of studies with protocol bars, the findings mentioned above suggest that PEEK is a promising material for im-plant dentistry.

In other situations, for example, when the All-on-Four® technique was used, the stress peak was higher for PEEK bars than conventional bars 31 . For zygomatic implants, there was no difference in tension between PEEK and the cobalt-chrome alloy 32 . Compressive strength was lower in PEEK bars than in nickel-chrome bars 16 .

The results of this study support the use of PEEK as an alternative for protocol bars, since it promoted a smaller misfit, being a functionally viable option, in addition to being a good aesthetic option, according to other studies 31, 33 . The differences between PEEK and cobalt-chrome bars can be explained by their surface features, regarding which the influence of particle size and uniformity, as well as the mechanical properties, have been reported 3 . Moreover, evidence is emerging that PEEK bars improve mastication performance, bite force capacity and occlusal pattern, in addition to providing greater patient sat-isfaction 34 .

The “counter-torque” response variable did not indicate any difference between materials. It is speculated that PEEK promoted the same passivity as the cobalt-chrome alloy, protecting the screw similarly. Like the current study, most studies on PEEK in oral rehabilitation are still experimental. Despite the need for larger long-term clinical studies, it is important to reinforce the evidence of experimental studies that support and increase the safety of using the material in clinical practice, which reinforces the relevance of the present study.

It is concluded that the PEEK protocol bar provided better fit of the mini abutments to the implants, even after mechanical cycling. The counter-torque of the screws was similar in all evaluated scenarios.