Servicios Personalizados

Revista

Articulo

Indicadores

-

Citado por SciELO

Citado por SciELO

Links relacionados

-

Similares en

SciELO

Similares en

SciELO

Compartir

Acta Odontológica Latinoamericana

versión On-line ISSN 1852-4834

Acta odontol. latinoam. vol.23 no.2 Buenos Aires set. 2010

ARTÍCULOS ORIGINALES

Influence of retentive areas associated to onlay preparations on the dimensional stability of silicone impression materials

Regis A. Yatsuda1, Adriano F. Lima2, Regiane Yatsuda3, Andrea N. Cavalcanti4, Cláudia I. Capp5, Moacyr D. Novelli6, Antonio A. de Cara5

1 Senior Reference Center of São Paulo State, SP, Brazil.

2 Department of Restorative Dentistry, Piracicaba School of Dentistry, State University of Campinas, Piracicaba, SP, Brazil.

3 Center of Technology in Health, Federal University of Bahia, Vitória da Conquista, BA, Brazil.

4 School of Dentistry, School of Medicine and Public Health of Bahia (EBMSP), Salvador, BA, Brazil.

5 Department of Restorative Dentistry School of Dentistry, University of Sao Paulo, Sao Paulo, Brazil.

6 Department of General Pathology, School of Dentistry, University of Sao Paulo, Sao Paulo, Brazil.

CORRESPONDENCE Prof.Regis Alfredo Yatsuda Rua Padre Jose Morschhauser, 204, Sao Paulo - SP, Brazil E-mail: reyatsuda@yahoo.com

ABSTRACT

This study evaluated the effect of retentive areas on onlay preparations on the dimensional alterations in condensation and addition silicone materials. A standard model with an onlay preparation was made. Each impression material was used through the double or simultaneous impression technique (n=25), resulting in a hundred impressions of the same model. Impressions were poured with type IV dental stone. Digital images were taken with a light microscope and the distances between the reference points created on the plaster dies were compared with the ones on the standard model. In the occlusal, mesial-medium and mesial-cervical segments, the double impression (DI) with condensation silicone presented similar values compared to the standard model. The values of the addition silicone with DI were similar to the standard model only in the mesial-occlusal segment. In the other segments (distal-cervical, distal-medium and distal-occlusal), all groups were statistically different from the control. It could be concluded that addition and condensation silicone impressions provided plaster dies with significant dimensional alterations in most of the evaluated areas when compared to the standard model. The retentive areas related to the onlay preparation influenced the dimensional stability of the addition and condensation silicone impressions.

Key words: Dental impression material; Onlay; Polyvinyl siloxane; Dental impression technique.

RESUMO

Influência de áreas retentivas de preparos do tipo onlay na estabilidade dimensional de materiais de moldagem

Este estudo avaliou as alteracoes dimensionais de silicones de condensacao e adicao usados em duas tecnicas como resultado de areas retentivas de preparos do tipo onlay. Um modelo padrao foi feito e vinte e cinco moldagens realizadas com os dois materiais, atraves da tecnica de dupla impressao ou impressao simultanea, e cada material resultou em 50 modelos de gesso. Imagens digitais foram feitas com um microscopio de luz e as distancias entre os pontos de referencia criados no modelo de gesso foram comparados aos pontos de referencia no modelo padrao. Nos segmentos oclusais, medio-mesial e cervico-mesial, a tecnica de dupla impressao (DI) com silicone de condensacao apresentou valores similares comparados ao modelo padrao. Os valores do silicone de adicao com DI foram similares ao modelo padrao somente no segmento mesio-oclusal. Nos outros segmentos (disto-cervical, medio-distal e disto-oclusal), todos os grupos foram estatisticamente diferentes do controle. Pode- se concluir que moldagens com silicone de adicao e condensacao conferem modelos de gesso com alteracoes dimensionais significativas na maioria das areas avaliadas, quando comparadas ao modelo padrao. As areas retentivas relacionadas ao preparo de onlay influenciaram na estabilidade dimensional das moldagens atraves dos silicones de condensacao e adicao.

Palabras chave: Materiais de moldagem dental; Onlay; Polivinil siloxano; Tecnicas de moldagem dental.

INTRODUCTION

There are several clinical situations in which the use of extensive indirect restorations is indicated. Teeth with great structure loss due to caries, endodontic treatments or fracture, require restorations to protect the dental remnants, such as indirect restorations (IR). These restorations reestablish form and function, and increase the longevity of the tooth. The process of performing indirect restorations involves various sequential steps. Impression is a clinical procedure used to get the most faithful replica of the dental preparation, and is considered as one of the most challenging procedures1. This step is very important because any inaccuracy in the impression process will be transmitted to the other steps, thus affecting the final quality of the IR. The elasticity of an impression material can avoid rips or plastic deformation when the material passes through retentive areas at the removal of the mold from patient’s mouth2. In normal clinical conditions, retentive areas are seen in unprepared adjacent teeth, in teeth with retentive dental preparations, in large interproximal spaces, in cervical areas or below the edges of the tooth preparation.

Previous in vitro studies have associated the properties of elastomeric materials with the presence of retentive areas in the tooth preparations for indirect restorations, especially crowns3,4. The purpose of the present study was to investigate this phenomenon in an onlay preparation, which is a tooth preparation commonly used in clinical practice. Two silicone impression materials and two techniques were tested. The null hypothesis of this study is that impression techniques and materials would produce casts with similar accuracy compared to a standard model.

MATERIALS AND METHODS

Standard model and impression

A replica of the dental arch (P-oclusal; Sao Paulo – SP; Brazil) was used to simulate a clinical situation with a prosthetic space in the inferior second premolar (tooth 45) region. After that, an onlay preparation was done involving the mesial-occlusal-distal surfaces at the gingival level, with a diamond bur (#2135, KG Sorensen; Sao Paulo; Brazil) in a highspeed handpiece under air-water spray refrigeration. Similar preparation design was used in a previous study, which evaluated the accuracy of impressions made with dual-arch tray5. Using the thermal expansion casting technique, a metallic replica in nickel-chromium alloy was made for the tooth 46. This replica was finished with aluminum oxide sandblasting, followed by an extra fine diamond bur (#2135FF, KG Sorensen; Sao Paulo; Brazil) and metal burnishing with a sequence of abrasive Viking rubber tips (KG Sorensen; Sao Paulo; Brazil). Reading reference points were made in the proximal and occlusal surfaces of the tooth preparation with a spherical carbide bur (FG 34; Jet Brand; U.S.A.). Six points were marked on each proximal surface of the dental preparation, distributed in duplicate at three distinct depths: cervical, medium and occlusal thirds. The occlusal third points were located at the edge regions of the proximal boxes, and the medium and cervical third points were located at the edge regions of the proximal grinding (slice). Two more points were marked on the occlusal surface, regions of intersection between vestibular and lingual sulcus, and the edge of the tooth preparation. Thus, six reference points were marked on each proximal surface, resulting in three distinct segments for each proximal surface: distalcervical (DC), distal-medium (DM), distal-occlusal (DO), mesial-cervical (MC), mesial-medium (MM), mesial-occlusal (MO). Two reference points were marked on the occlusal surface, resulting in an occlusal segment (O), resulting in seven segments for each tooth or die.

Tooth 46 was re-positioned in the replica of the dental arch. This dental arch, together with the metallic replica of the tooth preparation and the respective reference points were used as the standard model (Fig. 1). The standard model was duplicated with addition silicone (Flexitime; Heraeus; Germany) and poured with type IV dental stone (Durone; Dentsply; Sao Paulo; Brazil) in order to make an individual acrylic tray.

Fig. 1: Onlay preparation positioned on the standard mode.

Device for impression standardization

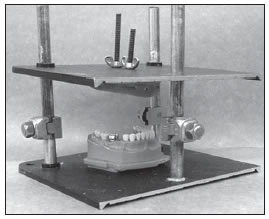

The device for impression standardization consisted of a stainless steel base 190 mm wide, 200 mm long and 5 mm thick, in which the standard model was centered and fixed with screws (Fig. 2). The individual tray was also fixed in a standardized position in relation to the standard model, keeping a uniform impression thickness of 3 mm, without producing pressure. This position allowed the vertical displacement of the impression tray, preventing improper lateral movements during its separation from the standard model.

Fig. 2: Device for impression standardization. The position allows the vertical displacement of the impression tray, preventing improper lateral movements during the separation from the standard model.

Reading device

The reference points in the plaster dies and the metallic tooth preparation were read with a light microscope (Citoval 2; Carl Zeiss; Jena; Germany), with 13× magnification and 0.01 mm accuracy. The images were captured and digitalized with a digital camera (Hyper HAD SSC DC14; Sony; Japan) connected to the microscope, and analyzed and processed with the software Microsoft Vidcap 32 (Microsoft Corp.; USA.). The distances between the reference points in the digitalized images were measured with the distance measurement tool of the ImageLab 2000, version 2.4 software.

Manipulation of the impression material

Two impression materials were used in this study: an addition silicone (AS) (Flexitime; Heraeus; Germany), and condensation silicone (CS) (Optosil Xantopren; Heraeus; Germany). Both materials were manipulated according to manufactures’ instructions; and in both impression techniques, the tray was covered with a layer of tray adhesive.

Simultaneous Impression (SI)

In the simultaneous impression technique, the putty material was placed in the individual tray, and a depression in the center of the impression material was made with digital pressure. The light material was manipulated by means of an auto-mixture system; and then it was injected in the relieved area and also on the area to be copied at the standard model. The filled tray was placed over the standard model through the impression device. After the setting time, which varied in accordance to the impression material used, the tray was removed in one sudden movement.

Double Impression (DI)

The double impression technique consisted of two steps. In the first step, the putty material was placed on the individual tray and positioned over the standard model through the impression device. After the setting time, the tray was removed. After a visual analysis of impression quality, the putty material was prepared by relieving retentive areas with a scalpel blade no 13 (Bard-Parker; Erwin Guth). The relieved areas were the interdental papillae regions next to the prosthetic space and excesses due to the silicone draining. Ridges to help light silicone draining were made in the vestibular and lingual regions of the putty silicone impression. In the second step, the impression was refilled with the light impression material. After that, the tray was repositioned over the standard model through the impression device. After the setting time of the light material, the tray was removed.

Plaster dies

After final analysis of the quality from the 100 impressions, a delay period of 20 minutes was allowed before pouring the dental stone, according to manufacturers’ instructions. A type IV dental stone (Durone; Dentsply; Sao Paulo; Brazil) was used, following the water - plaster ratio recommended by the manufacturer. The dental stone was manually mixed and impressions were manually filled using a vibration device. After 1 hour, the plaster die was separated from the respective impression.

Data collection and readings

The standard tooth preparation and plaster die readings were done by two calibrated observers. In the standard tooth preparation, each observer carried out ten readings per segment, totalizing twenty readings per segment. In the plaster dies, each observer carried out one reading for each segment, totalizing two readings per segment.

Statistical analysis

The means of the seven segments, in accordance with the different materials and impression techniques, were analyzed for normal distribution, and after confirming this data normality, they were analyzed with Repeated Measures ANOVA, and with the Tukey test for multiple comparison. The impression techniques and materials were compared with the ST (control group) through the One-way ANOVA/Dunnett test. Statistical analysis was carried out in the statistical software SAS, version 9.1, with a confidence interval of 95%.

RESULTS

Table 1 shows the results. In segments O, MM and MC; condensation silicone with double impression presented similar values compared to the control group, demonstrating the best behavior in this situation. The addition silicone with double impression technique presented similar values to the control group in segment MO. In segments DO, DM and DC, no experimental group presented similar values to the control group.

Table 1: Mean dimensions of stone casts according to impression technique (n=25) of the all segments analyzed.

DISCUSSION

The null hypothesis of this study was rejected, since the impression materials and techniques presented different values in most segments tested. The accuracy of tooth impressions has been studied in clinical and laboratory studies3,6-8. Impression materials can be categorized in two types: monophase and dual-phase. An impression technique with monophase materials consists of the use of a medium viscosity material, and the impression is made in a single-step procedure. When the impression technique uses a dual-phase material, like putty and light-body washes, it can be made in one or two steps 3. In this study, the accuracy of the impressions of an onlay preparation using one and two step techniques and two dual-phase materials was investigated. According to the results, a significant increase was detected on the O box measurements in all groups, except the condensation silicone with double impression technique, when compared to the standard group. These greater values coincided with the cervical of the vestibular and lingual region of the tooth, which are areas of greater retentiveness. During impression removal, the cervical region might have induced the deformation of the impression material, stretching it in vestibule-lingual direction and expanding its internal surface to a point that exceeded the elastic limits of the elastomeric material, causing permanent dimensional alterations. Similar behavior of these silicones has been observed in some previous studies9,10.

Another fact that might contribute to the deformation of the impressions could be the presence of the putty material in some regions of higher retentiveness. In areas such as the equatorial line of the tooth, the material was unable to gain complete elastic recovery, causing permanent deformations in the impression11. The better behavior of the double impression technique in some segments could be due to the relief of the retentive areas, which provide better reattachment. Also, the presence of only light material in the areas of higher retentiveness might have helped the elastic recovery. In the segments of the distal occlusal and mesial occlusal boxes, both impression materials provided smaller dies compared to the standard group. The dimensional reduction, in these two segments located in the intracoronal area of MOD preparation can be attributed to the permanent deformation suffered by the impression during its removal. The confined impression material enters in the cavity walls of the boxes and, under tension, suffers lateral retractions of the corresponding surface to the intracoronal area in the vestibule-lingual direction (walls of the boxes), and expansion of the corresponding surface of the impression to the extracoronary areas of the preparation (proximal slices and free surfaces).

The analysis of the distal-medium, distal-cervical segments in the plaster dies, as well as the mesialcervical segment showed expansion of its measurements in relation to the standard tooth preparation, with exception of the condensation silicone double impression technique in mesialcervical segment. These dimensional alterations may be related to the retentive anatomy of the standard tooth preparation. The distal surface of the lower first molar presents an anatomical characteristic that renders it a more retentive form compared to the mesial surface. In addition to presenting lower limits, the inclination of the coronary and root portions of the distal surface forms an acute angle to the col, conferring a greater degree of retentiveness in relation to the mesial surface. The cervical regions of the proximal surfaces, located next to the angle area of the col, are more retentive than the mesial regions. Also in the standard model, the presence of the lower second molar and the prosthetic space with the absence of the lower second premolar made the distal interproximal region still more retentive compared to the mesial. Beyond the retentiveness degree of the areas to be copied, there are factors that can influence the quality of the impressions, such as impression technique8,12, the bulk of the material13 and the impression material12. The use of a device for impression standardization made it possible to minimize interferences, allowing standardization of the individual impression position in relation to the standard model, keeping a uniform thickness of 3 mm for the impression, without exerting extreme pressure during impression’s nesting and removal. The thickness chosen for the impressions was the same as used in a previous investigation14.

In the present study, the impressions of addition and condensation silicones produced plaster dies with dimensional alterations in all analyzed areas, when compared to the standard model. Therefore, it might be suggested that the retentive areas located in the tooth with onlay preparation significantly influence the dimensional stability of the addition and condensation silicone impressions.

CONCLUSION

Within the limitations of this in vitro study, it can be concluded that: The retentive areas on the tooth with the onlay preparation influenced the dimensional stability of the addition and condensation silicone impressions, providing plaster dies with significant dimensional alterations in most of the evaluated areas when compared to the standard model, regardless of the technique used.

1. Beier US, Grunert I, Kulmer S, Dumfahrt H. Quality of impressions using hydrophilic polyvinyl siloxane in a clinical study of 249 patients. Int J Prosthodont 2007;20: 270-274. [ Links ]

2. Donovan TE, Chee WW. A review of contemporary impression materials and techniques. Dent Clin North Am 2004;48: vi-vii, 445-470. [ Links ]

3. Caputi S, Varvara G. Dimensional accuracy of resultant casts made by a monophase, one-step and two-step, and a novel two-step putty/light-body impression technique: an in vitro study. J Prosthet Dent 2008;99:274-281. [ Links ]

4. Balkenhol M, Ferger P, Wostmann B. Dimensional accuracy of 2-stage putty-wash impressions: influence of impression trays and viscosity. Int J Prosthodont 2007;20:573-575. [ Links ]

5. Wostmann B, Rehmann P, Balkenhol M. Accuracy of impressions obtained with dual-arch trays. Int J Prosthodont 2009; 22:158-160. [ Links ]

6. Samet N, Shohat M, Livny A, Weiss EI. A clinical evaluation of fixed partial denture impressions. J Prosthet Dent 2005; 94:112-117. [ Links ]

7. Millar BJ, Dunne SM, Robinson PB. In vitro study of the number of surface defects in monophase and two-phase addition silicone impressions. J Prosthet Dent 1998;80:32-35. [ Links ]

8. Nissan J, Laufer BZ, Brosh T, Assif D. Accuracy of three polyvinyl siloxane putty-wash impression techniques. J Prosthet Dent 2000;83:161-165. [ Links ]

9. Federick DR, Caputo A. Comparing the accuracy of reversible hydrocolloid and elastomeric impression materials. J Am Dent Assoc 1997;128:183-188. [ Links ]

10. Hansson O, Eklund J. Impressions for prosthodontic restorations reproducing narrow spaces and severe undercuts. Acta Odontol Scand 1988;46:199-206. [ Links ]

11. Morgano SM, Milot P, Ducharme P, Rose L. Ability of various impression materials to produce duplicate dies from successive impressions. J Prosthet Dent 1995;73:333-340. [ Links ]

12. Chen SY, Liang WM, Chen FN. Factors affecting the accuracy of elastometric impression materials. J Dent 2004;32:603-609. [ Links ]

13. Nissan J, Gross M, Shifman A, Assif D. Effect of wash bulk on the accuracy of polyvinyl siloxane putty-wash impressions. J Oral Rehabil 2002;29:357-361. [ Links ]

14. Eames WB, Wallace SW, Suway NB, Rogers LB. Accuracy and dimensional stability of elastomeric impression materials. J Prosthet Dent 1979;42:159-162. [ Links ]