Services on Demand

Journal

Article

Indicators

-

Cited by SciELO

Cited by SciELO

Related links

-

Similars in

SciELO

Similars in

SciELO

Share

Acta Odontológica Latinoamericana

On-line version ISSN 1852-4834

Acta odontol. latinoam. vol.28 no.2 Buenos Aires Aug. 2015

ARTÍCULOS ORIGINALES

Influence of alginate impression materials and storage time on surface detail reproduction and dimensional accuracy of stone models

Ricardo D. Guiraldo1, Ana F.F. Moreti1, Julia Martinelli1, Sandrine B. Berger1, Luciana L. Meneghel1, Rodrigo V. Caixeta1, Mário A.C. Sinhoreti2

1 Department of Restorative Dentistry, School of Dentistry, University North of Parana, Londrina, PR, Brazil

2 Department of Restorative Dentistry, Piracicaba Dental School, State University of Campinas, Piracicaba, SP, Brazil

CORRESPONDENCE Dr.Ricardo Danil Guiraldo University of North Parana - UNOPAR Rua Marselha, 183 86041-140 - Londrina, PR - Brazil e-mail: rdguiraldo@gmail.com

ABSTRACT

This study compared the surface detail reproduction and dimensional accuracy of stone models obtained from molds prepared using different alginate impression materials (Cavex ColorChange, Hydrogum 5, or Jeltrate Plus) and with different storage times (1, 3, and 5 days) to models from molds that were filled immediately with no storage time. The molds were prepared over a matrix containing 50-μm line, (ISO 1563 standard) under pressure with a perforated metal tray. The molds were removed 2 minutes after loss of sticky consistency and either filled immediately or stored in closed jars at 100% relative humidity and 37°C for 1, 3, or 5 days. The molds were filled with dental plaster (Durone IV). Surface detail reproduction and dimensional accuracy were evaluated using optical microscopy on the 50-μm wide line, which was 25 mm in length, according to ISO 1563 standard. The dimensional accuracy results (%) were subjected to analysis of variance. The 50-μm wide line (ISO 1563 standard) was completely reproduced by all alginate impression materials regardless of the storage time. There was no statistically significant difference in the mean dimensional accuracy values of stone models made from molds composed of different alginate impression materials and with different storage times (p = 0.989). In conclusion, storing the mold for five days prior to filling did not change the surface detail reproduction or dimensional accuracy of the alginates examined in this study.

Key words: Dental impression materials; Alginates; Dimensional measurement accuracy.

RESUMO

Influência dos alginatos e tempo de armazenamento na reprodução de detalhes da superfície e estabilidade dimensional de modelos de gesso

Este estudo comparou a reproducao de detalhes da superficie e estabilidade dimensional de modelos de gesso obtidos a partir de diferentes alginatos (Cavex ColorChange, Hydrogum 5, Jeltrate Plus) e com diferentes tempos de armazenagem (1, 3, e 5 dias) para modelos obtidos de moldes que foram preenchidos imediatamente sem tempo de armazenagem. Os moldes foram preparados sobre matriz contendo linha de 50 μm (norma ISO 1563) realizado sob pressao com moldeira de metal perfurada. Os moldes foram removidos 2 minutos apos a perda de consis - tencia pegajosa e preenchidos imediatamente ou armazenados em frascos fechados com temperatura (37°C) e umidade relativa (100%) controladas por 1, 3 ou 5 dias. Os moldes foram preenchidos com gesso dental (Durone IV). A reproducao de detalhes da superficie e a estabilidade dimensional foram avaliadas usando microscopia optica na linha 50 μm com 25 mm de comprimento, de acordo com a norma ISO 1563. Os resultados de estabilidade dimensional (%) foram submetidos a analise de variancia. A linha de 50 μm (norma ISO 1563) foi completamente reproduzida por todos os alginatos, independentemente do tempo de armazenagem. Nao houve diferenca estatisticamente significa - tiva nos valores medios de estabilidade de modelos de gesso obtidos de moldes de diferentes alginatos com diferentes tempos de armazenagem (p = 0.989). Em conclusao, o armazenamento do molde durante cinco dias antes do preenchimento nao alterou a reproducao de detalhes da superficie ou estabilidade dimensional dos alginatos examinadas neste estudo.

Palavras-chave: Materiais de moldagem dentais; Alginatos; Exatidao de mensuracao dimensional.

INTRODUCTION

Impression materials are used in dentistry to make accurate casts of oral tissues1. They must be capable of recording the anatomic topography of the desired area and remain dimensionally stable1. Alginate impression materials have been used in dentistry since 19472. Alginates are commonly used as a twocomponent system of powder and water. The powder contains sodium or potassium alginates (soluble alginates), diatomaceous earth acting as filler particles, calcium sulfate as a reactor, a fluoride as an accelerator, and sodium phosphate as a retarder3. In the alginate structure, gel fibrils are held together by primary bonds occurring due to the substitution of sodium ions by calcium ions on two neighboring molecules4. The gel forms as a complex, entangled structure, which traps sodium alginate that has not reacted with the calcium salt, excess water, charged particles, and reaction byproducts4. Under these conditions, the final alginate structure is very sensitive to conditions that can change the amount of water trapped in the fibrillar assembly. Consequently, the dimensional stability of an alginate mold is highly vulnerable the weather and moisture conditions during storage, before it is used to make the plaster model.

Surface detail reproduction and dimensional accuracy are necessary to make a true copy of the molded anatomical structures. Thus, these properties are used to analyze the quality of impression materials5. A previous study reported that the dimensional changes of alginate impressions in 100% relative humidity varied with the brand of the impression material6. However, molds are generally filled with plaster as quickly as possible, avoiding long exposure to air and the resulting syneresis and evaporation. If immediate casting is not possible, it is recommended that the mold be kept in an environment with 100% relative humidity to preserve the water balance within the material. Many alginate manufacturers recommend that models be made within 12 h of casting because increased dimensional changes occur after 12-24 h7. This study evaluated the surface detail reproduction and dimensional accuracy of stone models obtained from molds prepared using different alginate impression materials and with different storage times (1, 3, and 5 days) compared to stone models produced from molds that were filled immediately with no storage time. The null hypotheses tested were that the surface detail reproduction and dimensional accuracy of stone models are not affected by the alginate impression material or the storage time.

MATERIALS AND METHODS

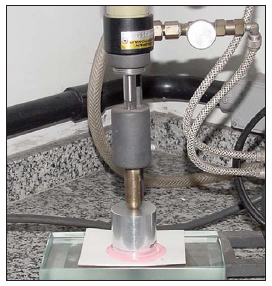

The following alginate impression materials were used in this study: Cavex ColorChange (batch number 120817, Cavex Holland BV, Haarlem, The Netherlands), Hydrogum 5 (batch number 161477, Zhermack, Badia Polesine, RO, Italy), and Jeltrate Plus (batch number 757944E, Dentsply Caulk, Milford, DE, USA). The dimensional accuracy and surface detail reproduction were evaluated in accordance with the ISO 1563 standard8. The molds were prepared over a matrix (38 mm outer diameter and 29.97 mm internal diameter) containing three parallel lines that were 20, 50, and 75 μm wide and 25 mm in length and spaced 2.5 mm apart. Two additional lines marked X and X' were used to determine the dimensional accuracy and surface detail reproduction on the 50-μm wide line (Fig. 1). Before performing the impression procedure, the matrix was ultrasonically cleaned and dried with compressed air. The alginate impression materials were prepared in accordance with the manufacturer's instructions. A perforated metal tray (31 mm internal diameter, 5 mm high) was placed on a glass plate and filled with the molding material (Fig. 1). The tray was joined to the matrix, and a pressure of 2 kgf was applied using a pneumatic press to simulate the impression process and allow for leakage of excess material1 (Fig. 2).

Fig. 1: Matrix in accordance with the ISO 1563 standard and tray.

Fig. 2: Method of positioning of the tray and matrix with a pressure of 2 kgf using a pneumatic press.

The molds were removed 2 minutes after loss of sticky consistency. Then the molds were rinsed with 150 mL of distilled water and dried. For the control groups, the molds were immediately filled with gypsum plaster (Durone IV, batch number 821320F; Dentsply Caulk). In the other groups, the molds were sealed in closed jars at 100% relative humidity (humidifier) and stored at 37°C (greenhouse) for 1, 3, or 5 days and then cast.

Thus, the samples were divided into 12 groups (n = 5) according to storage time and alginate impression material: Group 1: no storage time (control group) + Jeltrate Plus; Group 2: no storage time (control group) + Cavex ColorChange; Group 3: no storage time (control group) + Hydrogum 5; Group 4: stored for 1 day + Jeltrate Plus; Group 5: stored for 1 day + Cavex ColorChange; Group 6: stored for 1 day + Hydrogum 5; Group 7: stored for 3 days + Jeltrate Plus; Group 8: stored for 3 days + Cavex ColorChange; Group 9: stored for 3 days + Hydrogum 5; Group 10: stored for 5 days + Jeltrate Plus; Group 11: stored for 5 days + Cavex ColorChange; and Group 12: stored for 5 days + Hydrogum 5. The stone models were separated from the tray containing the alginate 1 h after the start of stone mixing.

Measurements of surface detail reproduction were performed using an optical microscope (SZM; Bel Engineering SRL, MI, Italy). The stone models were examined under low-angle illumination at magnifications of ×4 to ×12 to determine whether the 50-μm wide line was completely reproduced over the full 25 mm length between the intersecting reference lines (X and X'), in accordance with the ISO 1563 standard (13). Dimensional accuracy measurements were performed on the stone models using an optical microscope (STM; Olympus Optical, Co., Ltd., Japan) with an accuracy of 0.0005 mm. The dimensional accuracy was expressed as a percentage (L) and was calculated in accordance with ISO 15638 standard using the equation: L = [(L2 - L1) / L1] x 100, in which L1 is the distance between the lines on the matrix and L2 is the distance between the lines on the stone model. Then, 100% was added to the results of the equation and the dimensional accuracy results were subjected to the Kolmogorov-Smirnov test for normality, and then to two-way ANOVA (material x storage time).

RESULTS

The surface details of all alginate impression materials were fully replicated regardless of storage time (100% of the 5 samples in the 12 groups). There was no statistically significant difference in the mean values of dimensional accuracy in combinations among the storage times and alginate impression materials (p = 0.989) or independent factors (material and storage time) (Table 1).

Table 1: Mean values of dimensional accuracy (%) for combinations among the storage times and alginate impression materials.

DISCUSSION

Irreversible hydrocolloids are hydrophilic materials that can capture the details of hard and soft tissues in the presence of moisture9. These water-based materials are inexpensive and can easily be manipulated by following the manufacturer's instructions9. Concerns regarding their performance include their low tear strength, dimensional instability when pouring is delayed, and inability to produce accurate casts upon repouring10. Thus, it is not surprising that the dimensional stability of various brands of irreversible hydrocolloids decreases with increased storage time9. This decrease in dimensional stability is caused by the gain or loss of water from the impression after setting. Imbibition (absorption of fluid by a colloid that results in swelling), evaporation, and syneresis (expulsion of a liquid from a gel) result in dimensional changes9. The effects of water evaporation and imbibition can be minimized by pouring the impression as soon as possible9. Moreover, irreversible hydrocolloid impressions may be wrapped in a damp paper towel for shipment to the dental laboratory, rather than pouring the casts immediately in the dental office11. Thus, it would be interesting to compare the dimensional accuracy of casts made from irreversible hydrocolloids (i.e., Cavex Color Change and Hydrogum 5), which manufacturers say work better if the cast is poured within 5 days, with a conventional hydrocolloid (Jeltrate Plus). To examine this, we delayed pouring the gypsum to simulate routine clinical procedures by storing the molds for 1, 3, or 5 days.

Studies have supported pouring casts immediately or within 10 minutes12,13, without wrapping them in a wet towel to avoid any absorption of water by the material14. Thus, impressions made using irreversible hydrocolloid materials may undergo dimensional changes if not poured immediately because of water exchange with the surrounding environment or by syneresis, which is inherent to the material. In studies of different brands of hydrocolloid materials with different study conditions and storage intervals, researchers have reported that pouring casts from irreversible hydrocolloid impressions immediately or within 10 minutes to 1 hour after making the impression helps to decrease errors and avoid the discrepancies that may occur with prolonged storage12,15. Other studies have shown that the impressions made using certain brands of hydro - colloid materials may be stored for up to 3 hours before being poured6,16. In the present study, regardless of the brand of alginate or storage time, there was no statistical difference in surface detail reproduction or dimensional accuracy measured in stone models made from molds within 5 days. Similar results were observed in another study which showed that two irreversible hydrocolloid substitutes (Alginot FS and Position PentaQuick) were dimensionally stable for up to 7 days17. Moreover, a previous study, in which impressions were rinsed with water and stored in a sealed plastic container that was maintained in an environment of 100% humidity, showed that the cast surfaces poured after storage were better than those poured immediately after rinsing18. Tan et al.18 reported that this was because the exudates from syneresis, which retard the setting of stone and affect the cast surface, decreased during storage. The decrease in exudates during impression storage was reported to decrease the scratch depth of stone models19. This was not observed in the present study.

However, the syneresis phenomenon did not have a negative effect on the surfaces of the plaster models. The setting expansion of gypsum plaster might have compensated the contraction in the alginate caused by syneresis. Torassian et al.17 compared the dimensional stability of typodont and plaster models cast from molds made from two alginates (Identic and imprEssix) at 72 h, 120 h, and 168 h. Measurements were made in several directions, including the anteriorposterior (measured from the central pit of the first molar to the midline face of the respective central incisor), transverse (measured from the central pit of the first molar to the central pit of the contralateral first molar), and vertical (measured from the incisal edge at the midline of the maxillary right and left central incisors to the gingival margin) dimensions17. The Identic alginate exhibited shrinkage in all dimensions, and the intercanine width and vertical measurements of the imprEssix alginate decreased over time. In the present study, there was no statistical difference in dimensions when different methodologies and alginate materials were used. In this study, the ISO 1563 standard was used because dimensional changes could clinically affect dental work involving alginate molds with different storage times. Thus, before carrying out clinical procedures, it is necessary to conduct additional tests using different methodologies, such as those described in the aforementioned study,17 with the materials used in the present study. Acceptable methods of measuring the dimensional accuracy of casts include measuring calipers5,20, micrometers21, dial gauges22, and measuring microscopes1,23. The latter device was used in the present study due to its high accuracy (0.5 μm). The largest dimensional deviation between the matrix and stone models was 0.16% in Group 5 (stored for 1 day + Cavex ColorChange), which did not differ statistically from the other material/storage combinations. Alginate impression materials are typically recommended for prosthetics and orthodontic purposes where the level of accuracy is perceived as less critical5. However, our results suggest that they have sufficient dimensional accuracy for other uses as well. Furthermore, it should be noted that the study was conducted in the laboratory using a strict protocol for all sample preparation steps. To extrapolate these results to the clinical reality, this strict protocol should be performed and other properties, which were not examined in this study, should be tested in future. Thus, based on the results of this study, the null hypothesis was accepted: there was no difference in the dimensional accuracy of models cast from different alginate molds and stored for different lengths of time.

CONCLUSION

In conclusion, the results indicate there is no difference in surface detail reproduction and dimensional accuracy in plaster models made from alginate molds, regardless of differences in storage time or alginate used. Thus, storing the mold for five days prior to filling did not change the surface detail replication or the dimensional accuracy in this study. However, further studies are needed to confirm these findings clinically.

ACKNOWLEDGMENTS

The authors thank Engineer Marcos Blanco Cangiani for assistance with matrix and Figures and Professor Murilo Baena Lopes for his assistance with the Figures.

1. Guiraldo RD, Borsato TT, Berger SB, Lopes MB, Gonini-Jr A, Sinhoreti MA. Surface detail reproduction and dimensional accuracy of stone models: influence of disinfectant solutions and alginate impression materials. Braz Dent J 2012; 23: 417-421. [ Links ]

2. Hansson O, Eklund J. A historical review of hydrocolloids and an investigation of the dimensional accuracy of the new alginates for crown and bridge impressions when using stock trays. Swed Dent J 1984; 8:81-95. [ Links ]

3. Carlo HL, Fonseca RB, Goncalves LS, Correr-Sobrinho L, Soares CJ, Sinhoreti MA. Analysis of filler particle levels and sizes in dental alginates. Mater Res 2010;13:261-264. [ Links ]

4. Anusavice K.J. Phillips' Science of Dental Materials, 11th ed, Philadelphia Saunders Company, 2003. [ Links ]

5. Taylor RL, Wright PS, Maryan C. Disinfection procedures: their effect on the dimensional accuracy and surface quality of irreversible hydrocolloid impression materials and gypsum casts. Dent Mater 2002; 18:103-110. [ Links ]

6. Hiraguchi H, Nakagawa H, Wakashima M, Miyanaga K, Sakaguchi S, Nishiyama M. Effect of storage period of alginate impressions following spray with disinfectant solutions on the dimensional accuracy and deformation of stone models. Dent Mater J 2005; 24:36-42. [ Links ]

7. Craig RG. Review of dental impression materials. Adv Dent Res 1988; 2:51-64. [ Links ]

8. ISO 1563 "Dental alginate impression material" Geneva Switzerland, 1990. [ Links ]

9. Nassar U, Aziz T, Flores-Mir C. Dimensional stability of irreversible hydrocolloid impression materials as a function of pouring time: a systematic review. J Prosthet Dent 2011; 106:126-133. [ Links ]

10. Rubel BS. Impression materials: A comparative review of impression materials most commonly used in restorative dentistry. Dent Clin North Am 2007; 51:629-642. [ Links ]

11. Nassar U, Hussein B, Oko A, Carey JP, Flores-Mir C. Dimensional accuracy of 2 irreversible hydrocolloid alternative impression materials with immediate and delayed pouring. J Can Dent Assoc 2012; 78:c2. [ Links ]

12. Shaba OP, Adegbulugbe IC, Oderinu OH. Dimensional stability of alginate impression material over a four hours time frame. Niger Q J Hosp Med 2007;17:1-4. [ Links ]

13. Chen SY, Liang WM, Chen FN. Factors affecting the accuracy of elastometric impression materials. J Dent 2004; 32:603-609. [ Links ]

14. Donovan TE, Chee WW. A review of contemporary impression materials and techniques. Dent Clin North Am 2004; 48:445-470. [ Links ]

15. Walker MP, Burckhard J, Mitts DA, Williams KB. Dimensional change over time of extended-storage alginate impression materials. Angle Orthod 2010; 80:1110-1115. [ Links ]

16. Hiraguchi H, Kaketani M, Hirose H, Yoneyama T. The influence of storing alginate impressions sprayed with disinfectant on dimensional accuracy and deformation of maxillary edentulous stone models. Dent Mat J 2010; 29:309-315. [ Links ]

17. Torassian G, Kau CH, English JD, Powers J, Bussa HI, Marie Salas-Lopez A, Corbett JA. Digital models vs. plaster models using alginate and alginate substitute materials. Angle Orthod 2010; 80:474-481. [ Links ]

18. Tan HK, Hooper PM, Buttar IA, Wolfaardt JF. Effects of disinfecting irreversible hydrocolloid impressions on the resultant gypsum casts: Part III - Dimensional changes. J Prosthet Dent 1993; 70:532-537. [ Links ]

19. Hiraguchi H1, Nakagawa H, Wakashima M, Miyanaga K, Saigo M, Nishiyama M. Effects of disinfecting alginate impressions on the scratch hardness of stone models. Dent Mater J 2006; 25:172-176. [ Links ]

20. Woodward JD, Morris JC, Khan Z. Accuracy of stone casts produced by perforated trays and nonperforated trays. J Prosthet Dent 1985; 53:347-350. [ Links ]

21. Rueggeberg FA, Beall FE, Kelly MT, Schuster GS. Sodium hypochlorite disinfection of irreversible hydrocolloid impression material. J Prosthet Dent 1992; 67:628-631. [ Links ]

22. Millstein PL. Determining the accuracy of gypsum casts made from type IV dental stone. J Oral Rehabil 1992; 19: 239-243. [ Links ]

23. Hilton TJ, Schwartz RS, Bradley DV Jr. Immersion disinfection of irreversible hydrocolloid impressions. Part 2: Effects on gypsum casts. Int J Prosthodont 1994; 7:424-433. [ Links ]